If the steps above do not solve the problem or if the repairs involved are too

complex, contact a qualified technician.

IMPORTANT!

Be CERTAIN to shut off the Plasma Cutter, and disconnect it from power and air before

adjusting, cleaning, or repairing the unit. A technician should discharge all capacitors before

performing any internal procedures.

Page 21SKU 91814

For technical questions, please call 1-800-444-3353

TROUBLESHOOTING (CONTINUED)

You may wish to take note

of the setting required for

this metal thickness.

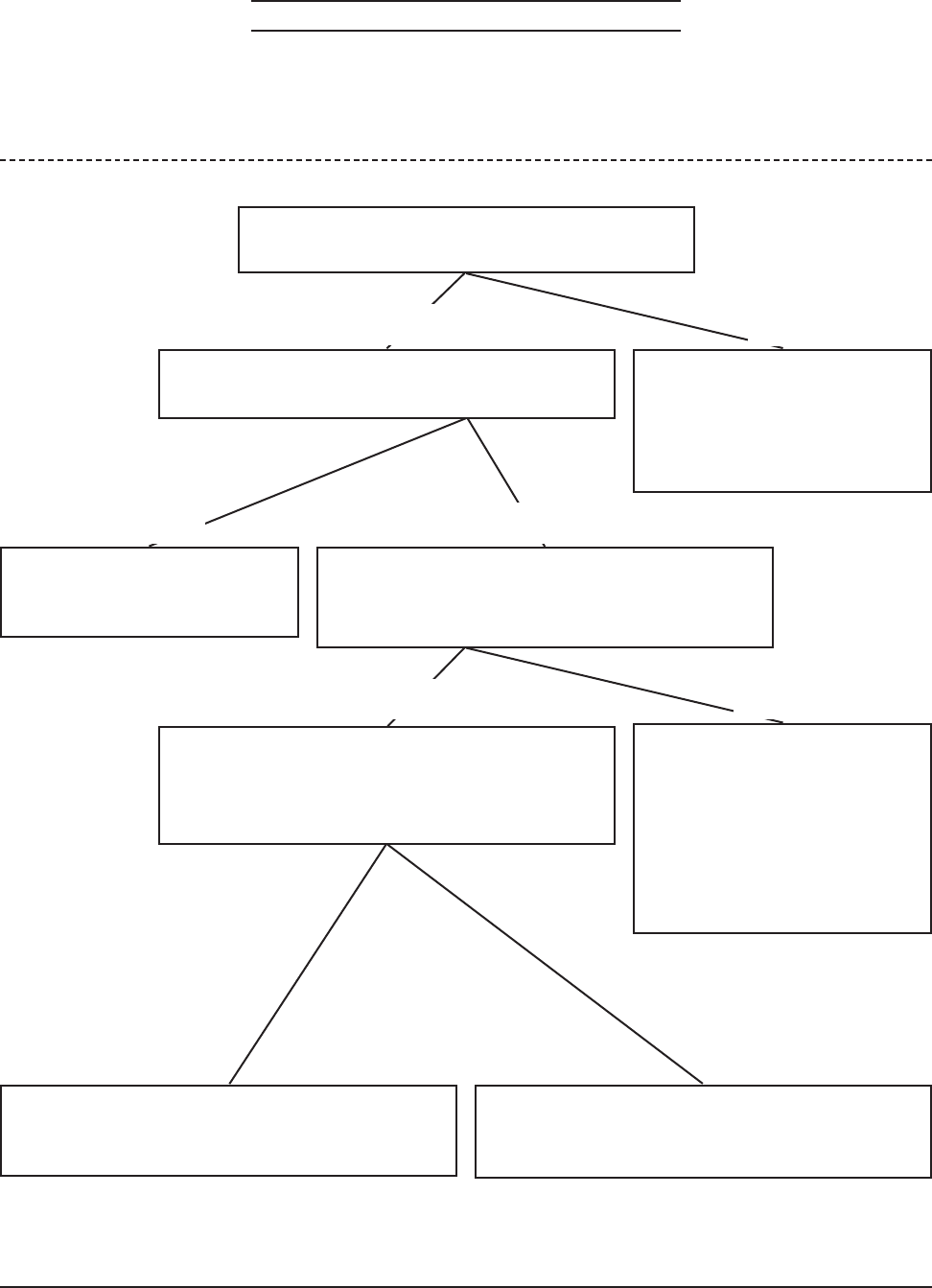

CUT GOES ONLY PARTIALLY THROUGH THE WORKPIECE

The Air pressure may be too low.

Check the Air Pressure setting on the

regulator’s gauge.

Turn up the current adjustment knob and

try again.

Material being cut is too thick. Maximum

thickness for steel is 3/8”.

You may wish to cut the

object along one side and

then cut along the other.

If this is not practical, use

a more powerful Cutter.

WITHIN THICKNESS

RANGE

MATERIAL

TOO THICK

a. Verify that the compres-

sor is delivering at least

3.5 CFM @ 65 PSI to the

tool.

b. The Regulator on the

unit must be set to at

least 60 PSI.

AIR

PRESSURE

AIR

PRESSURE

PROBLEM

CORRECTED

PROBLEM PERSISTS AT

MAXIMUM SETTING

Disconnect the Torch Cables.

Disassemble the torch assembly and

inspect all internal components, as ex-

plained on page 13.

Replace any damaged or missing compo-

nents and reassemble carefully, following

the directions on page 13.

TORCH IN GOOD

CONDITION

DAMAGED

COMPONENTS FOUND

Try cutting at a slower pace, the arc may

not have enough time to cut through the

workpiece.

REV 07/05