Page 15For technical questions, please call 1-800-444-3353.SKU 98265

5. Remove the blade and replace with a

new one. Make sure the arrow on the

blade matches the direction of the arrow

embossed on the blade cover.

6. With the at wrench in place again,

reinstall the blade’s hex bolt turning

clockwise, and tighten securely.

7. Replace the clear Cover and secure with

the three Hex Screws removed earlier.

Cleaning the Saw

1. With the saw turned off and the cord

pulled out from the outlet, wipe down all

of the external parts of the unit with a

damp (not dripping wet) sponge.

2. Make sure that the Water Tray is also

cleaned and a container of some type is

located below the Drain Plug (E03). Re-

move the plug and drain the water and

silt accumulated by the cutting operation.

3. Use more water to clean out the residual

silt from the water tray.

4. Replace the Drain Plug. Check condition

of the O-Ring (E02) and replace if torn or

cut.

5. The cleaning process is faster and easier

if the unit is tipped on end and carefully

(do not wet the motor) hosed down.

6. Wipe the entire unit down including the

sides and Sliding Bars (C16).

7. Clean out the pump by removing the

Filter (A26), placing the pump into a con-

tainer of clean water, and running it to

pump out any remaining silt. Back ush

the screen Filter (A26) and replace onto

the pump.

REV 10b

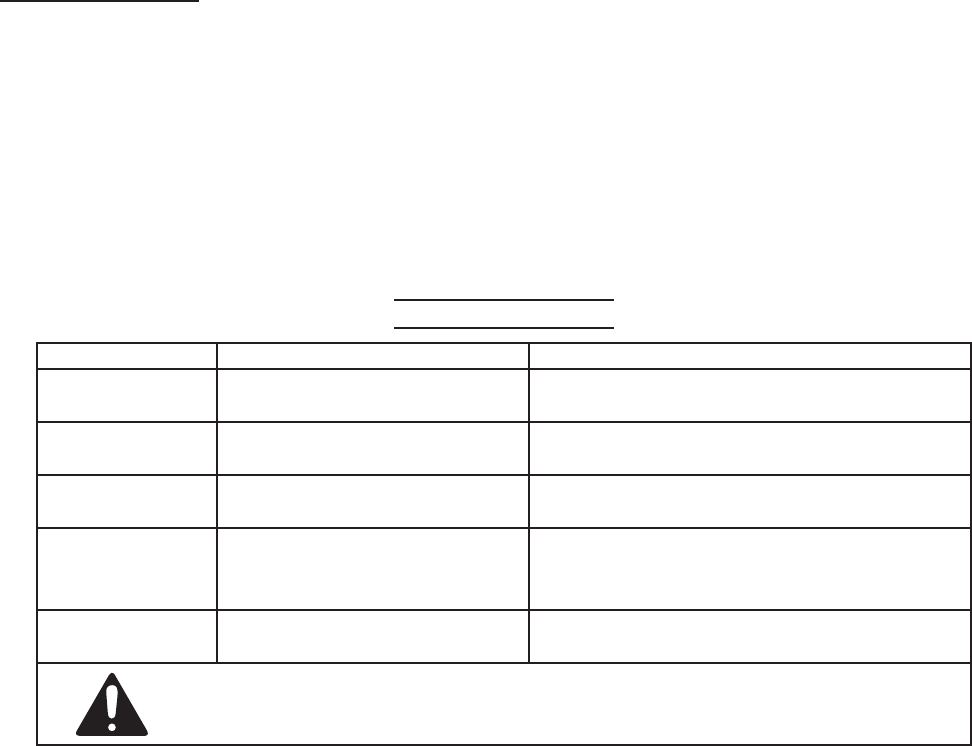

Troubleshooting

Problem Possible Causes Likely Solutions

Tool will not start

1. No power at outlet.

2. Cord not connected.

1. Check power at outlet.

2. Check that cord is plugged in.

Blade spins slowly

1. Arbor shaft binding

2. Motor brushes worn

1. Check shaft for free spinning

2. Replace brushes

Excessive vibration 1. Bent or off-balance blade

2. Bent Arbor Shaft

1. Replace blade with new one

2. Check shaft for run-out

Running hot;

excess smoke

1. Water ow problem.

2. Not enough water

3. Running with hot/warm water

1. Check connection

2. Add proper amount of water

3. Always run with cold water

Restricted Saw

Travel

1. Dry or damaged Holder.

2. Bent Sliding Bars.

1. Lubricate or service Holder components.

2. Replace Sliding Bars.

Follow all safety precautions whenever diagnosing or servicing the

tool. Disconnect power supply before service.