38

CUTTING CROWN MOLDING

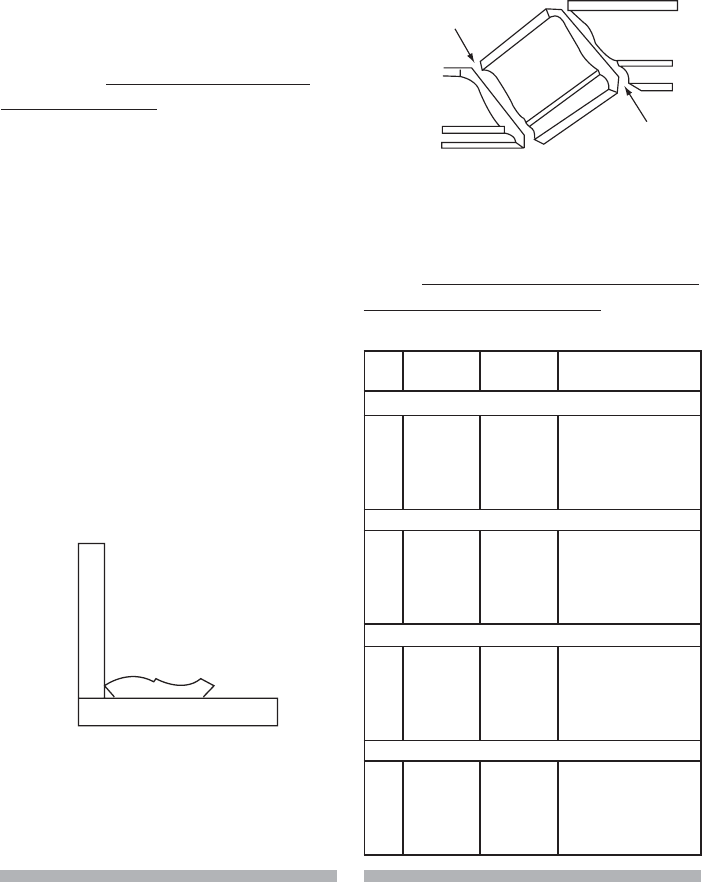

(FIG. HH, II)

Your compound miter saw is suited

for the diffi cult task of cutting crown

molding. To fi t properly, crown molding

must be compound-mitered with

extreme accuracy. The two surfaces

on a piece of crown molding that fi t

fl at against the ceiling and wall are at

angles that, when added together,

equal exactly 90°.

Most crown molding has a top rear

angle (the section that fi ts fl at against

the ceiling) of 52°and a bottom rear

angle (the section that fi ts fl at against

the wall) of 38°.

In order to accurately cut crown

molding for a 90° inside or outside

corner, lay the molding with its broad

back surface fl at on the saw table.

When setting the bevel and miter angles

for compound miters, remember that the

settings are interdependent; changing

one changes the other, as well.

Fig. HH

Bevel/Miter Settings

Fig. II

Settings for standard crown molding

lying flat on compound miter saw

table

NOTE: The chart below references

a compound cut for crown molding

ONLY WHEN THE ANGLE BETWEEN

THE WALLS EQUALS 90°.

F

e

n

c

e

Miter saw table

Inside corner

Outside corner

Compound cut crown moldings

OR

OL

IR

IL

Bevel/Miter Settings

KEY BEVEL

SETTING

MITER

SETTING

TYPE OF CUT

Inside corner-Left side

IL

33.9° 31.6° Right 1. Position top of molding

against fence.

2. Miter table set at

RIGHT 31.6°.

3. LEFT side is fi nished

piece.

Inside corner-Right side

IR

33.9° 31.6° Left 1. Position bottom of

molding against fence.

2. Miter table set at LEFT

31.6°.

3. LEFT side is fi nished

piece.

Outside corner-Left side

OL

33.9° 31.6° Left 1. Position bottom of

molding against fence.

2. Miter table set at LEFT

31.6°.

3. RIGHT side is fi nished

piece.

Outside corner-Right side

OR

33.9° 31.6° Left 1. Position top of molding

against fence.

2. Miter table set at

RIGHT 31.6°.

3. RIGHT side is fi nished

piece.