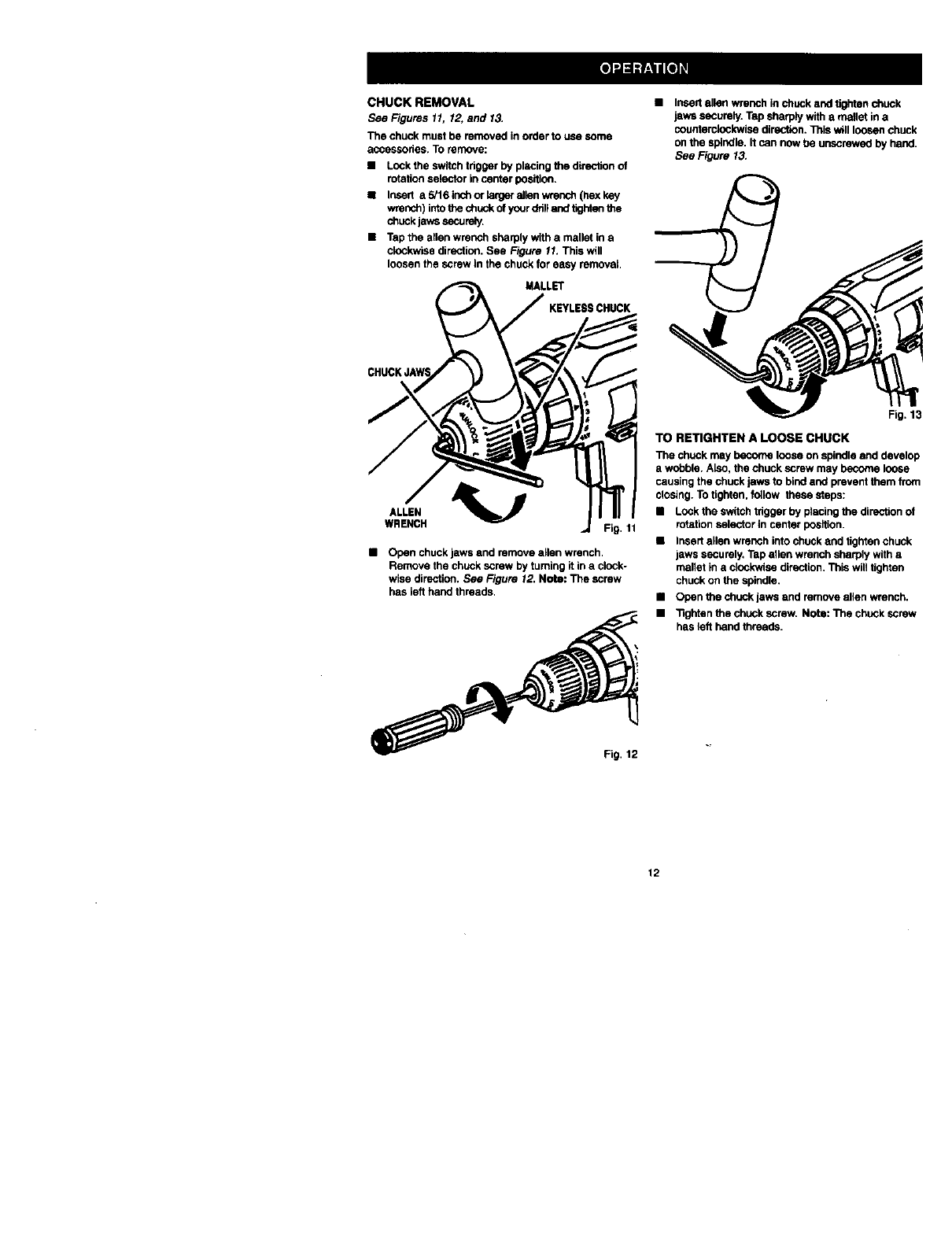

CHUCKREMOVAL

See Figures 11, 12, and 13.

The chuck must be removed in order to use some

accessodes. To remove:

• Lock the switch tdgger by placing the direction of

rotation selector in center position,

• Insert a5/16inchorlargerallenwmnch(haxkey

wrench) intc the chuck ofyour drilland tighten tha

chuck jaws securely.

• Tap the a,an wretch sharply with a mallet in a

c_ockwise direction. See Figure 11. This will

loosen the screw in the chuck for easy removal

MALLET

KETLESSCHUCK

ALLEN

WRENCH

Fig. 11

• Open chuck jaws and remove allen wrench.

Remove the chuck screw by turning d in a clock-

wise direction. See Figure 12, Note: The screw

has loft hand threads,

• Insert allen wrench in chuck and tighten chuck

jaws securely. Tap sharply with a mallet in a

counterclockwise direction. This will loosen chuck

on the spindle, n can now be unscrewed by hand.

See Figure 13.

Fig, 13

TO RETIGHTEN A LOOSE CHUCK

The chuck may become loose on spindle and develop

a wobble. Also, the chuck screw may become loose

causing the chuck jaws to bind and prevent them from

closing. To tighten, follow these steps:

• Lock the switch tdgger by placing the direction of

rotetion selector in center position.

• Insert allen wrench into chuck and tighten chuck

jaws securely, Tap allen wrench sharply with a

mallet in a clockwise direction, This will tighten

chuck on the spindle,

• Open the chuck jaws and remove allen wrench.

• "Rghten the chuck screw, Note: The chuck screw

has left hand threads.

Fig. 12

12