27

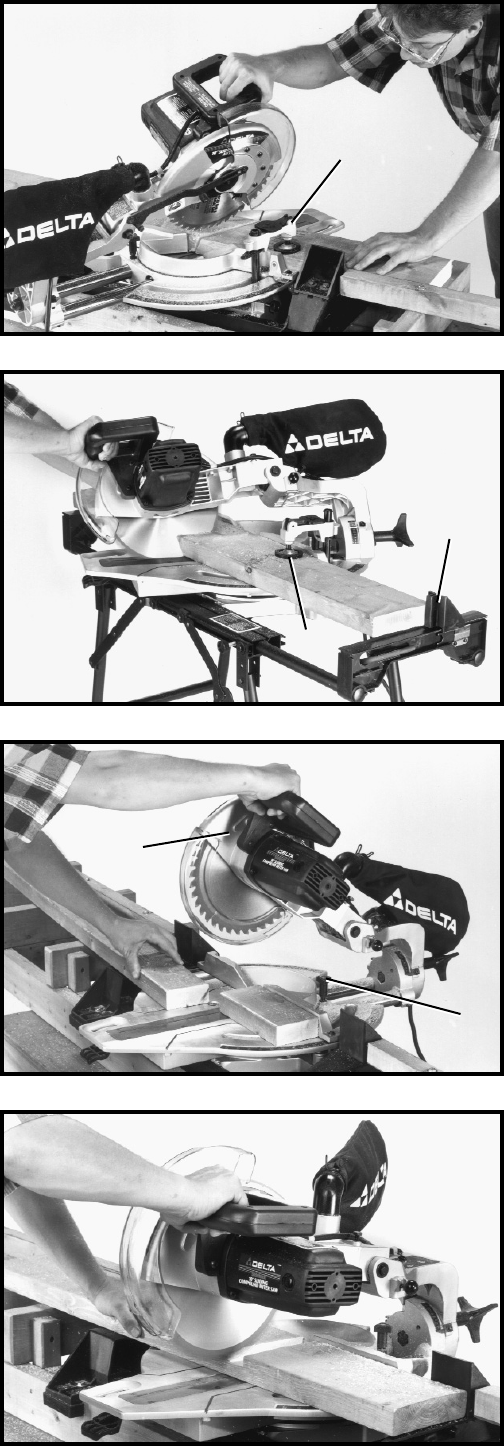

Fig. 79

Fig. 80

Fig. 81

Fig. 82

USING THE WORK CLAMP

AND STOCK STOP

Figures 79 and 80 illustrate a compound miter/bevel cut

being made using the work clamp (A), which is used to

firmly hold the work against the table, and the auxiliary

fence (B), which has been adjusted to be used as a

stock stop. IMPORTANT: When the work clamp (A) is

used in conjunction with the stock stop (B), the work

clamp (A) and stock stop (B) Fig. 80, should ALWAYS be

on the same side of the saw blade. This is important as

it prevents the free end of the workpiece from binding

between the blade and the stock stop.

USING SAW AS

A CHOP SAW

The sliding action of the saw must be locked in the

rear position, as shown in Fig. 81, by tightening lock

knob (A), when cutting material that is narrow enough to

allow the saw blade to cut through in a chopping motion.

The cuttinghead (B) is pushed straight down to make the

cut. After the cut is completed, release the switch trigger

and let the blade come to a complete stop before

returning the cuttinghead to the up position.

DADO CUTTING

Dado cutting can easily be accomplished with your

compound slide saw, as shown in Fig. 82, using a single

saw blade and moving the workpiece sideways the width

of the saw blade after each cut. The cut is made in the

conventional way as explained in the section “CORRECT

OPERATING PROCEDURE” and the downward travel of

the saw blade is adjusted for the depth of the dado as

explained in the section “ADJUSTING DOWNWARD

TRAVEL OF SAW BLADE”.

A

A

B

B

A