20

BEVEL RIPPING

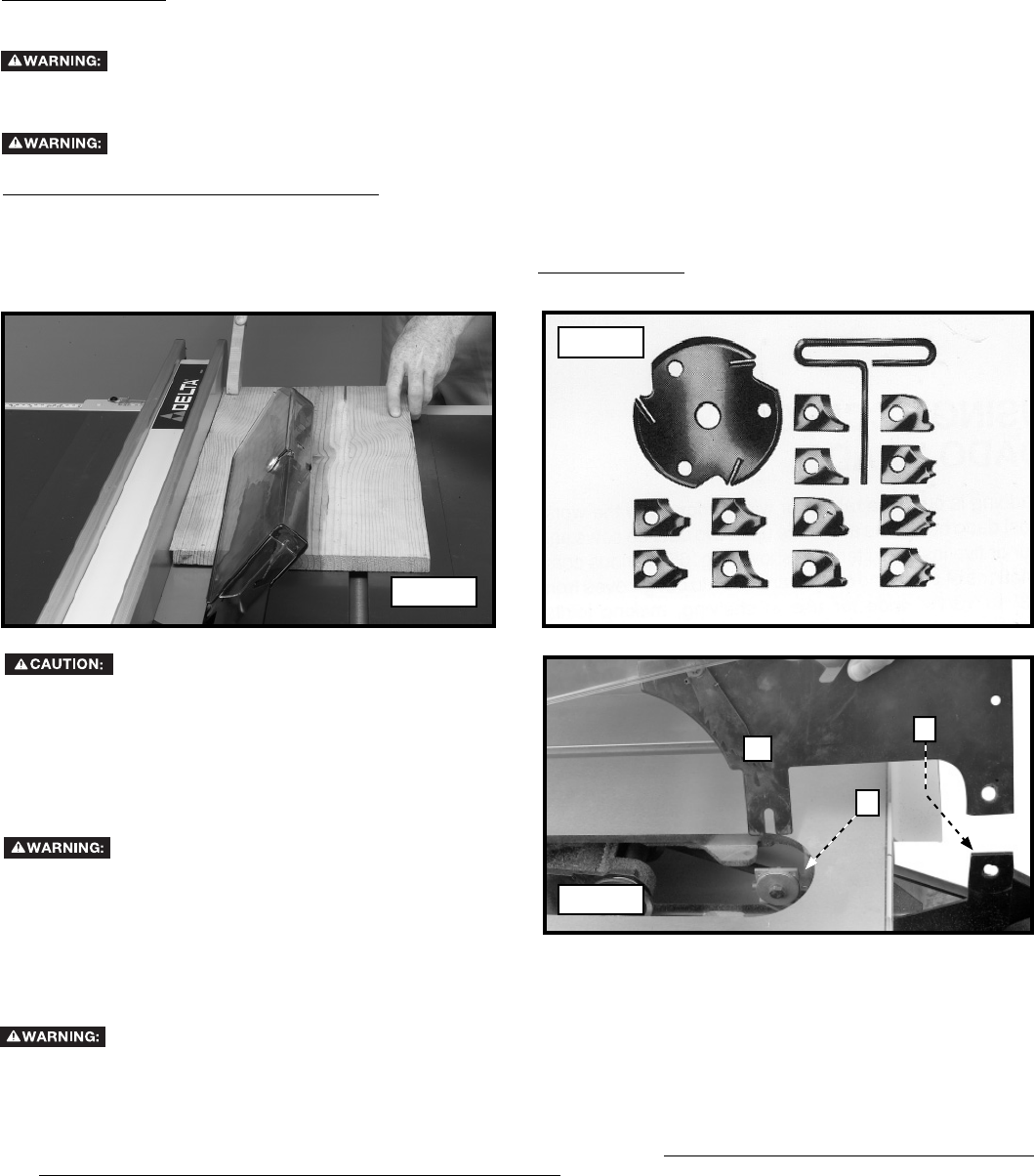

Bevel ripping (Fig. 47) is the same as ripping except the bevel angle is set to an angle other than 0°.

When possible, place the fence on the right side of the blade so that the blade is tilted away from the

fence and hands. keep your hands clear of the blade and use a pushstick to feed the workpiece if there is less than 6”

between the fence and the blade.

Use caution when starting the cut to prevent binding of the guard against the workpiece.

For certain cutting operations (dadoing and

moulding) where the workpiece is not cut completely

through, the blade guard and splitter assembly cannot be

used. Loosen screws at (G) and (H) Fig. 49. Lift and remove

the blade guard and splitter assembly (W).

Use pushsticks, hold-downs, jigs, fixtures,

or featherboards to help guide and control the workpiece

when the guard cannot be used.

HOW TO USE A MOULDING CUTTERHEAD

NOTE: The outside arbor flange cannot be used with the moulding cutterhead. Tighten the arbor nut against the cutterhead body.

Do not lose the outside arbor flange. It will be needed when reattaching a blade to the arbor.

Always return and fasten the blade guard and splitter assembly to its proper operating position for

normal thru-sawing operations.

Fig. 47

Fig. 48

Fig. 49

W

H

G

Moulding is cutting a shape on the edge or face of the workpiece with a special moulding cutterhead.

The moulding head consists of a cutterhead in which can be mounted various shapes of steel knives (Fig. 48). Each of the

three knives in a set is fitted into a groove in the cutterhead and securely clamped with a screw. Keep the knife grooves free

of sawdust to allow the cutter to seating properly.

1. You can easily attach a moulding cutterhead (A) Fig. 50 to the saw arbor. Also, you must use the accessory moulding

cutterhead table insert (B) in place of the standard table insert.

2. When using the moulding cutterhead, add wood-facing (C) to the face of the rip fence (Fig. 51). The wood-facing is

attached to the fence with wood screws through holes which must be drilled in the fence. Stock that is 3/4" inch thick is

suitable for most work, although an occasional job may require 1" facing.

3. Position the wood-facing over the cutterhead with the cutterhead below the surface of the table. Turn the saw on

and raise the cutterhead. The cutterhead will cut its own groove in the wood-facing. Fig. 51 shows a typical moulding

operation.