17

CUTTING A SHOULDER

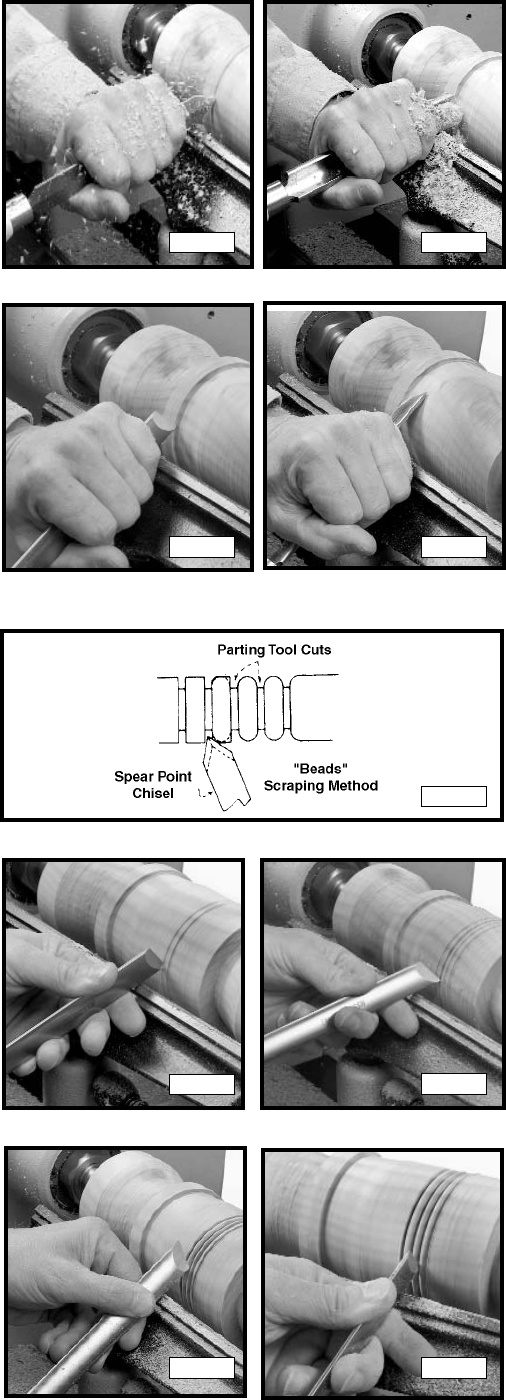

Use the parting tool first to reduce the wood to within

1/16” of the required shoulder and diameter (Fig. 43).

Clean the waste stock out with the gouge (Fig. 44), then

use the skew for the actual cutting of the shoulder (Figs.

45A and 45B), which is a duplication of squaring an end.

The skew then makes the horizontal cut, but in a differ-

ent manner from plain cylinder work. If the shoulder is

long, use the ordinary skew position for the outer portion

of the cut. At the angle between the horizontal and ver-

tical cuts, the heel of the chisel moves into a position

tangent between the skew and the cylinder (Fig. 46). In

this position, raise the handle of the chisel slightly to

allow it to cut while the tool moves along the rest. Use a

very light cut to produce smooth work. The heel of the

skew can be used for making the entire cut, if desired,

but the cut, whether in this position or any other posi-

tion, should not be picked up directly at the end of the

stock. Horizontal cuts started directly from the end of

the work will have a tendency to bite into the wood,

often ruining the entire piece. Always run off the end and

not into it. Where a very short shoulder makes this

impossible, use the skew in a flat scraping position. If

the cutting technique is used, engage only with the heel

of skew in a very light cut.

CUTTING SMALL BEADS

Beads can be scraped or cut. Using the spear chisel is

the easiest method of scraping, and works to best

advantage on beads separated by parting tool cuts

(Fig. 46). Scraping is slower than cutting and is not as

clean, but it has the advantage of protecting the work

from long gashes.

Cutting beads quickly and accurately with the small

skew is one of the most difficult lathe operations.

Various working methods can be used . The first cut is a

vertical incision at the point where the two curved sur-

faces will eventually come together. Make this cut with

either heel or toe of skew. Fig. 47 shows the use of the

toe. Place the skew at right angles to the work . The chis-

el is flat on its side at the start, and is evenly rotated

through the successive stages of the cut (Figs. 48, 49

and 50). At the same time, the chisel is pulled slightly

backward to maintain the cutting point. The entire cut is

made with the heel of chisel. The opposite side of the

bead is cut in the same manner, one cut serving to

produce the full shape in each instance. This action

produces beads that are beautifully smooth and

polished, and the technique is well worth mastering.

Fig. 43

Fig. 44

Fig. 45

Fig. 46

Fig. 46

Fig. 47

Fig. 48

Fig. 49

Fig. 50