21—ENG

MGP-SL10120H-2A

TROUBLESHOOTING GUIDE

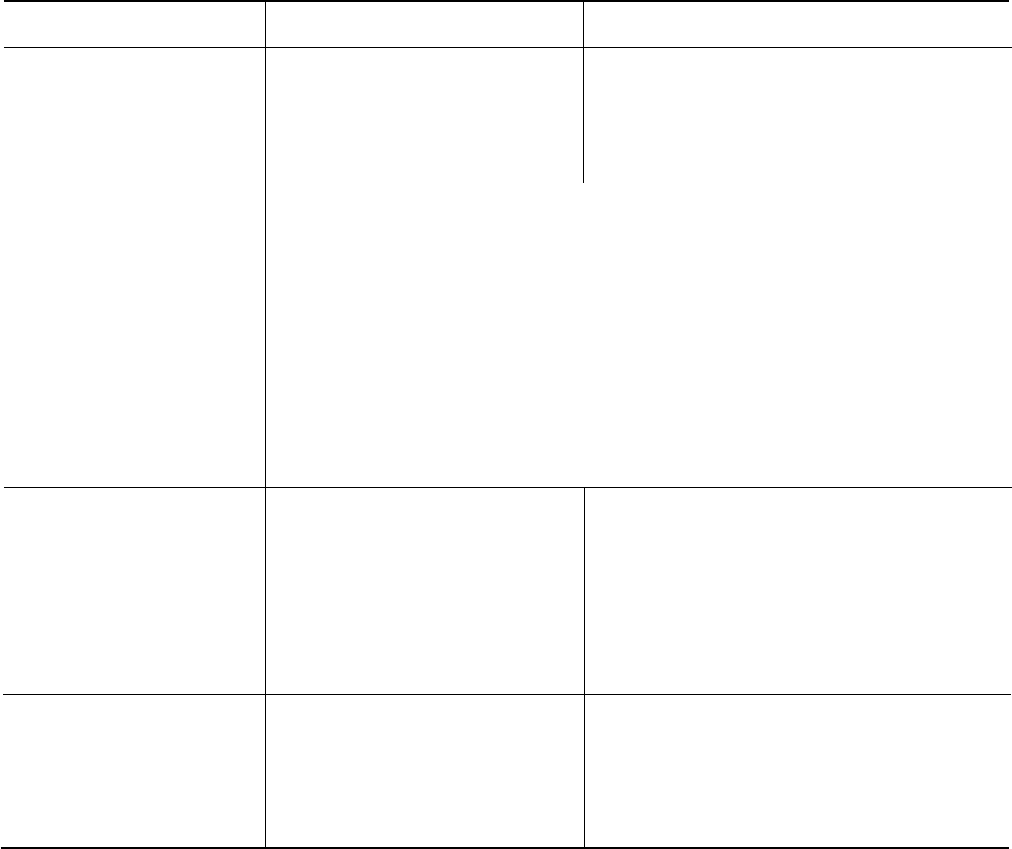

PROBLEM

CAUSE CORRECTION

Too many motor starts per hour. Consult Service Center.

Check electrical hookup and installation data or con-

sult electrician.

Improper wiring gauge.

Incorrect voltage.

Water in pump crankcase; oil

appears milky in color.

Liquid water or moisture in air

lines.

Humid operating conditions.

Relocate compressor outfit, or change oil frequently.

Motor overheating.

(Continued)

Consult Service Center.

Install compressed air dryer sized for the flow and

dryness level required.

Unit not reaching proper operating

temperature because the compres-

sor runs infrequently and is oversized

for the air requirement.

Condensation forms in air lines when

the warm compressed air coming

from the air tank starts to cool down

as it travels through the air lines.

NOTENOTE

NOTENOTE

NOTE

Current style electric motors run relatively hot under normal operating

conditions, with reasonable compressor loading. This condition is normal

and no adjustment is necessary.

Under normal operating conditions, the motor amperage draw will not

exceed the nameplate amperage rating, plus the service factor, as it appears

on the electric motor. If a condition of sustained high amperage exists, refer

to service checks above and/or consult electrician. If cause cannot be isolated

by an electrician, consult with Service Center for additional assistance.