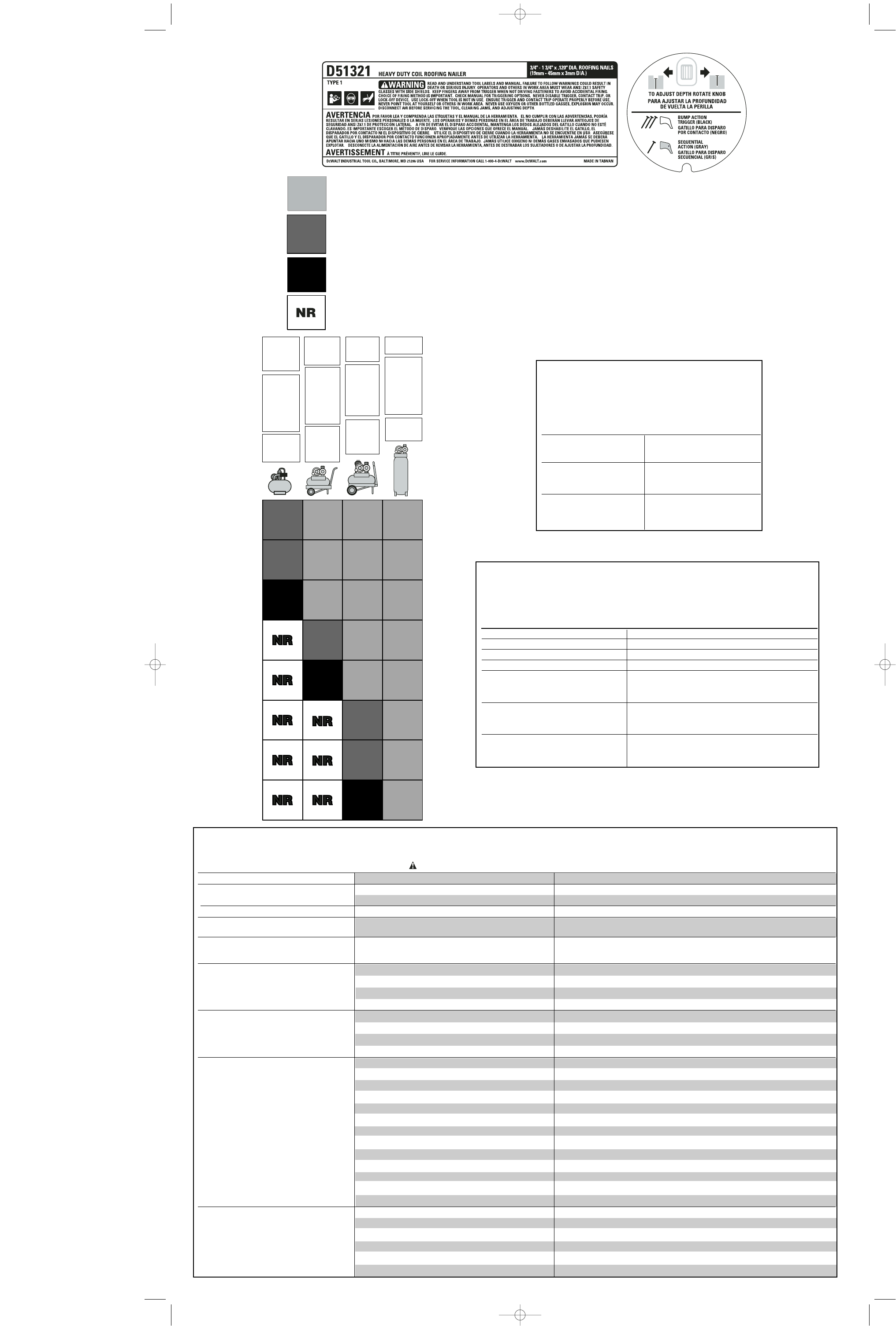

Compressor will be sufficient for tools at all production rates.

Le compresseur peut actionner tout outil, quel que soit le taux de production.

El compresor será suficiente para las herramientas a todo índice de producción.

Compressor will be sufficient at slow or moderate production rates, but may have difficulty at very rapid rates.

Le compresseur peut actionner des outils à des taux de production faibles ou modérés, mais peut avoir de la difficulté à

des taux très élevés.

El compresor será suficiente a índices de producción lentos o moderados pero tendrá dificultad con índices demasiado rápidos.

Compressor will be adequate only when tools are utilized at slow production rates. (punch-out or occasional use)

Le compresseur ne sera vraiment efficace que lorsque les outils sont utilisés à de faibles taux de production (p. ex., lors de

travaux rapides ou occasionnels).

El compresor será adecuado sólo cuando las herramientas sean utilizadas a índices de producción lentos (perforación o uso

ocasional).

Not Recommended

Taux non recommandés

No se recomienda

Troubleshooting Guide

MANY COMMON PROBLEMS CAN BE SOLVED EASILY BY UTILIZING THE CHART BELOW. FOR MORE SERIOUS OR PERSISTENT PROBLEMS,

CONTACTA D

EWALT SERVICE CENTER OR CALL 1-(800)-4-DEWALT.

DISCONNECT AIR FROM TOOL BEFORE ALL REPAIRS

Trigger valve housing leaks O-ring or valve stem failure Replace valve using: Trigger Valve Kit: Cat. # D510005

Top cap leaks air Loose cap screws Tighten cap screws using appropriate Allen wrench

Damaged or worn gasket or O-ring Replace gasket/O-rings using: O-ring Repair Kit, Cat. # D513211

Exhaust leaks Main seal or O-ring damaged, debris in tool. Replace gasket/O-rings using: O-ring Repair Kit, Cat. # D513211

Air leaks around nose when Damaged or worn O-rings Replace gasket/O-rings using: O-ring Repair Kit, Cat. # D513211

tool is at rest. (Driver blade in up position)

Air leaks around nose when tool is in

actuated position. (Driver blade in Damaged or worn bumper Replace bumper using: Bumper Kit, Cat. # D513213

down position)

Tool does not cycle in cold weather Tool not receiving air Check air supply

Valve may be frozen Warm up tool

Damaged or worn O-rings Replace gasket/O-rings using: O-ring Repair Kit, Cat. # D513211

Broken or damaged driver blade Replace Driver Blade Kit: Cat. # D513212

Lack of power; sluggish Low air pressure Check air supply

Lack of lubrication Lubricate tool using approved pneumatic tool oil.

Damaged or worn O-rings Replace gasket/O-rings using: O-ring Repair Kit, Cat # D513211

Exhaust port blocked or clogged Disconnect air, remove exhaust plate from top of tool, clean port

Skipping nails; intermittent feed Air restricted Check air supply and couplers

Lack of lubrication Lubricate tool using approved pneumatic tool oil

Nose piece screws loose Tighten nosepiece screws using appropriate allen wrench

Wrong size/angle fasteners Use only recommended fasteners

Dirty canister Clean canister track and nosepiece

Worn canister Replace canister

Broken or damaged driver blade Replace Driver Blade Kit; Cat. # D513212

Trigger valve O-ring worn or damaged Replace valve using: Trigger Valve Kit; Cat. # D510005

Worn piston O-ring Replace Piston O-Ring using: O-Ring Repair Kit, Cat.# D513211

Worn or damaged check pawl and/or feed pawl Replace check pawl and/or feed pawl

Canister loose Check that canister latch is holding firmly

Nail platform at incorrect setting Set nail platform to proper nail setting

Feed piston O-ring worn or damaged Replace feed piston O-ring using: O-Ring Repair Kit, Cat. # D513211

Fasteners jam in tool Driver channel in nose piece worn Replace nosepiece

Wrong size/ angle fasteners Use only recommended fasteners

Canister loose Check that canister screws are holding firmly

Worn driver blade Replace Driver Blade Kit; Cat # D513212

Nose piece screws loose Tighten nosepiece screws using appropriate Allen wrench

Nails not feeding properly Ensure nails are feeding properly into nose.

NAIL SPECIFICATIONS

D51321 COIL ROOFING NAILER

CARACTÉRISTIQUES DES CLOUS

D51321 CLOUEUSE À BOBINE POUR TOITURES

ESPECIFICACIONES DE LOS CLAVOS

D51321 CLAVADORA PARA TECHADO EN ROLLO

Nail Lengths .75'' - 1.75''

Longueur 20 – 40 mm (0,75 – 1,75 po.)

Largo de clavos 20 – 40 mm (0,75 – 1,75 pulg.)

Shank Diameters .120

Diamètre de tige 3 mm (0,120 po.)

Diámetro del vástago 3 mm (0,120 pulg.)

Nail Coil Angle 15˚

Angle de la bobine 15°

Ángulo del rollo de clavos 15˚

TOOL SPECIFICATIONS

D51321 COIL ROOFING NAILER

CARACTÉRISTIQUES DE L’OUTIL

D51321 CLOUEUSE À BOBINE POUR TOITURES

ESPECIFICACIONES DE LA HERRAMIENTA

D51321 CLAVADORA PARA TECHADO EN ROLLO

Height / Hauteur / Altura 11.4'' (289,6 mm)

Width / Largeur / Ancho 4.6" (118,1 mm)

Length / Longueur / Largo 10.6'' (269,7 mm)

Weight / Poids / Peso 4.90 lbs. (2,22 kg)

Recommended Operating Pressure 70 - 120 psig (4.9 - 8.3 bar, 5 to 8.5 kg/cm

2

)

Pression d’utilisation recommandée de 5 à 8,5 kg/cm

2

(70 à 120 lb/po

2

ou 4,9 à 8,3 bar)

Presión de operación recomendada 70 - 120 psi (4,9 – 8,3 bar, 5 a 8,5 kg/cm

2

)

Air Consumption per 100 cycles 4.15 scfm @ 100 psi

Consommation d’air par 100 cycles 4,15 scfm à 100 psi (0,12 scmm a 6,9 bar)

Consumo de aire por cada 100 ciclos 4,15 scfm a 100 psi (0,12 scmm a 6,9 bar)

Loading capacity Up to 120 nails

Capacité de charge Jusqu’à 120 clous

Capacidad de carga Hasta 120 clavos

5.5 HP Gas

2 HP Elec.

8 - 9 CFM

Portable

Handcarry

3.2 - 4 CFM

8 HP Gas

14 - 16

CFM

Industrial

23+ CFM

Petit

outil

portatif

5,4 – 6,8 CMM

(3,2 – 4 CFM)

Outil à gaz

(5,5 hp)

Outil élec-

trique

(2 hp)

13,6 – 15,3

CMM

(8 - 9 CFM)

Outil à gaz

(8 hp)

23,8 – 27,2

CMM

(14 – 16

CFM)

Outil indus-

triel

39,1+ CMM

(23+ CFM)

Portátil

5,4 – 6,8 CMM

(3,2 – 4 CFM)

5,5 HP Gas

2 HP Elec.

13,6 – 15,3

CMM

(8 - 9 CFM)

8 HP Gas

23,8 – 27,2

CMM

(14 – 16

CFM)

Industrial

39,1+ CMM

(23+ CFM)

NUMBER OF TOOLS CONNECTED TO COMPRESSOR

NOMBRE D’OUTILS RACCORDÉS AU COMPRESSEUR

NÚMERO DE HERRAMIENTAS CONECTADAS AL COMPRESOR

1

2

3

4

5

6

7

8+

Fig. 10

614989-00, D51321 3/19/04 5:45 PM Page 6