16

English

2. Move compressor into an inclined position so drain valve (J) is

at the lowest point (this will assist in removing moisture, dirt, etc.

from air tanks)

3. Place a suitable container under the drain valve to catch

discharge.

4. Grasp black lever on drain valve.

5. Slowly rotate lever to gradually bleed air from air tank.

CAUTION: Risk of Property Damage. Drain water from air tank

may contain oil and rust which can cause stains.

6. When air tank pressure gauge reads 10 PSI (68.9 kPa), rotate

valve to the fully open position.

7. Close drain valve when finished.

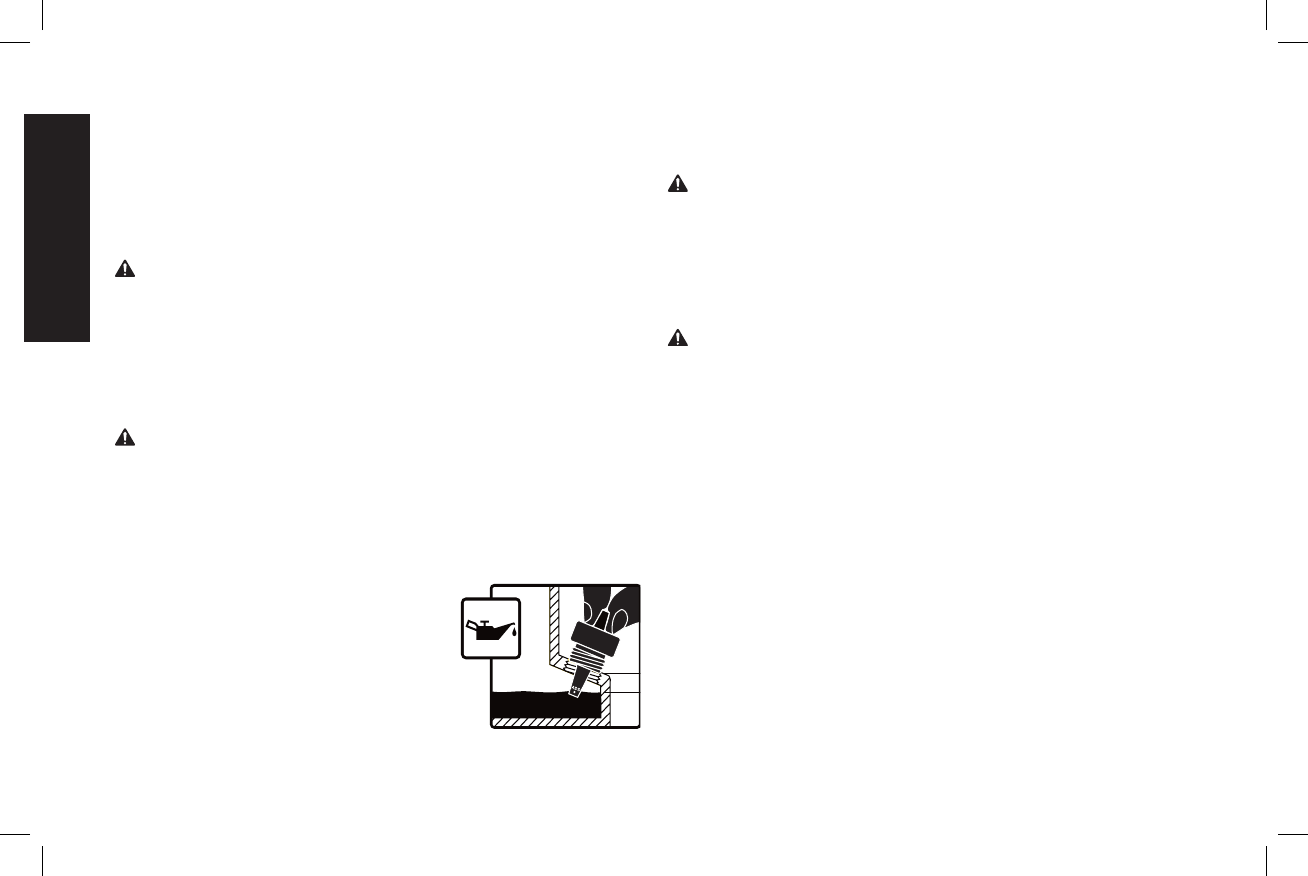

Compressor Pump Oil (Fig. 1)

CHECKING OIL

WARNING: Hot surfaces. Risk of burn. Aftercooler, pump head,

and surrounding parts are very hot, do not touch (see the Hot

Surfaces identified in Fig. 2). Allow compressor to cool prior to

servicing.

1. Ensure engine ON/OFF switch (C) is in the OFF Position.

2. Place unit on a flat level surface.

3. Remove dipstick (L) and wipe clean.

4. Insert and remove dipstick without

MAX.

OIL

MIN.

threading dipstick into crankcase as

shown in figure.

5. Check the oil level on dipstick.

If oil level is at or below “Add”,

oil needs to be added. Add D

EWALT

synthetic oil to the proper maximum

level as shown in figure.

NOTE: When filling the crankcase, the oil flows very slowly

into the pump. If the oil is added too quickly, it will overflow and

appear to be full.

CAUTION: Risk of Unsafe Operation. Overfilling with oil will cause

premature compressor failure. Do not overfill.

6. Replace dipstick and tighten securely.

CHANGING OIL

NOTE: Pump oil contains substances that are regulated and must

be disposed of in accordance with local, state and federal laws and

regulations.

WARNING: Hot surfaces. Risk of burn. Aftercooler, pump head,

and surrounding parts are very hot, do not touch (see the Hot

Surfaces identified in Fig. 2). Allow compressor to cool prior to

servicing.

1. Ensure engine ON/OFF switch (C) is in the OFF Position.

2. Allow the unit to cool.

3. Disconnect spark plug wire.

4. Drain air tank.

5. Locate a suitable container under pump drain plug (J).

6. Remove the dipstick (L) from crank case.

7. Remove the oil drain plug (M).

8. Allow ample time for all oil to drain out. (Tilting the compressor

towards the drain plug will assist in draining.)

9. Install the oil drain plug.

10. Fill pump with D

EWALT synthetic compressor oil. Oil should not

exceed top raised line on side of crackcase. (Oil will be even with

bottom of threads in crankcase fill port.)

11. Install dipstick.

12. Reconnect spark plug wire.