English

20

• When the laser is not in use, store it in the kit box provided.

• Do not store your laser in the kit box if the laser is wet. Dry

exterior parts with a soft, dry cloth and allow the laser to air dry.

• Do not store your laser at temperatures below 0˚F (-18˚C) or

above 105˚F (41˚C).

WARNING: Never use solvents or other harsh chemicals for

cleaning the non-metallic parts of the tool. These chemicals may

weaken the materials used in these parts. Use a cloth dampened

only with water and mild soap. Never let any liquid get inside the

unit; never immerse any part of the unit into a liquid. Never use

compressed air to clean the laser.

Field Calibration Check (Fig. 17, 18)

Field calibration checks should be done frequently. This section

provides instructions for performing simple field calibration checks

of your D

EWALT Rotary Laser. Field calibration checks do not

calibrate the laser. That is, these checks do not correct errors in

the leveling or plumbing capability of the laser. Instead, the checks

indicate whether or not the laser is providing a correct level and

plumb line. These checks cannot take the place of professional

calibration performed by a D

EWALT service center.

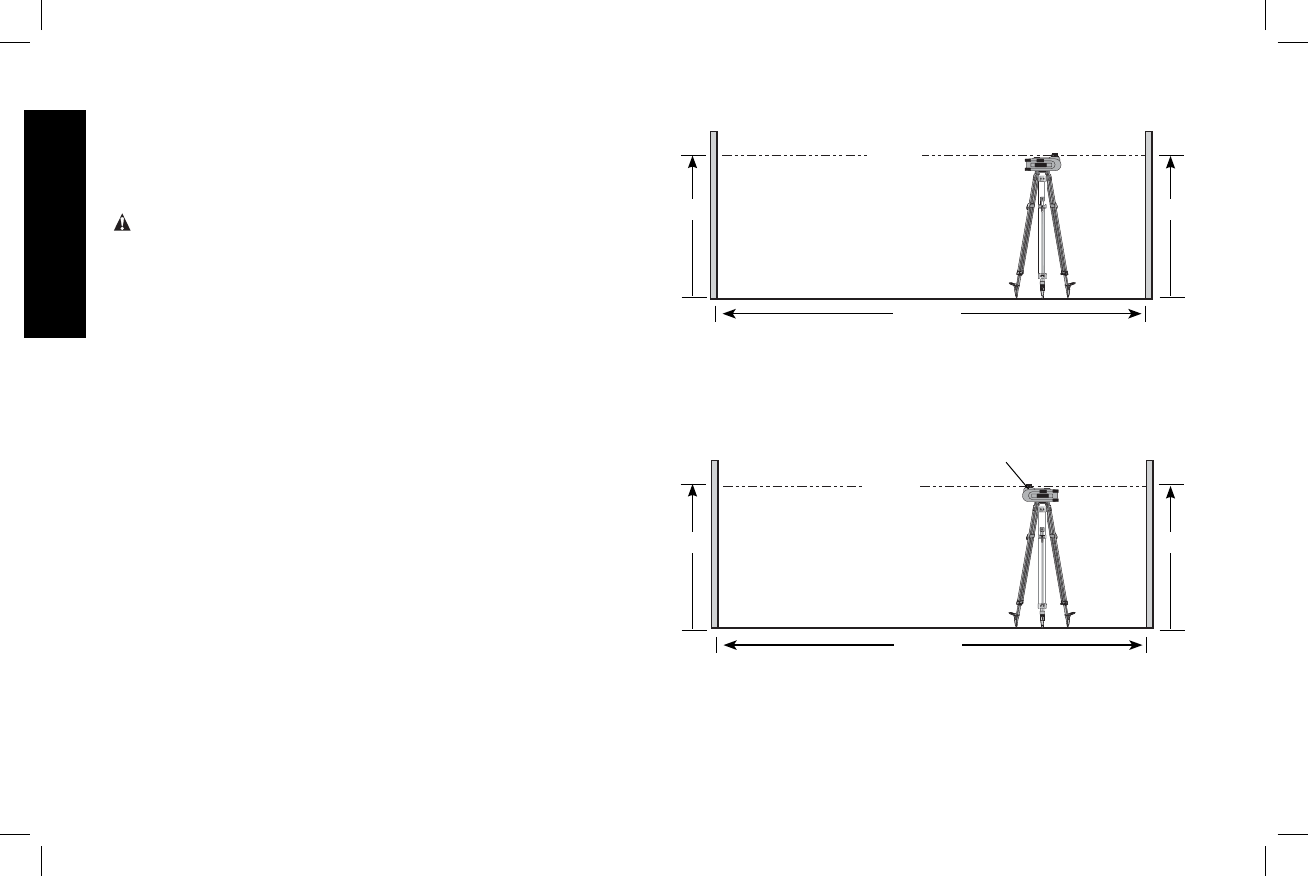

LEVEL CALIBRATION CHECK (X-AXIS)

1. Set up a tripod between two walls that are at least 50 feet apart.

The exact location of the tripod is not critical.

2. Mount the laser unit on the tripod so that the X-axis points

directly toward one of the walls.

3. Turn the laser unit on and allow it to self-level.

4. Mark and measure points A and B on the walls as shown in

Figure 17.

BEAM

BA

FIG. 17

L

5. Turn the entire laser unit 180º so the X-axis points directly

toward the opposite wall.

6. Allow the laser unit to self-level, and mark and measure points

AA and BB on the walls as shown in Figure 18.

LASER UNIT ROTATED 180˚

BEAM

L

BBAA

FIG. 18

7. Calculate the total error using the equation:

Total Error = (AA – A) – (BB– B)

8. Compare total error to the allowable limits shown in the following

table.