7

English

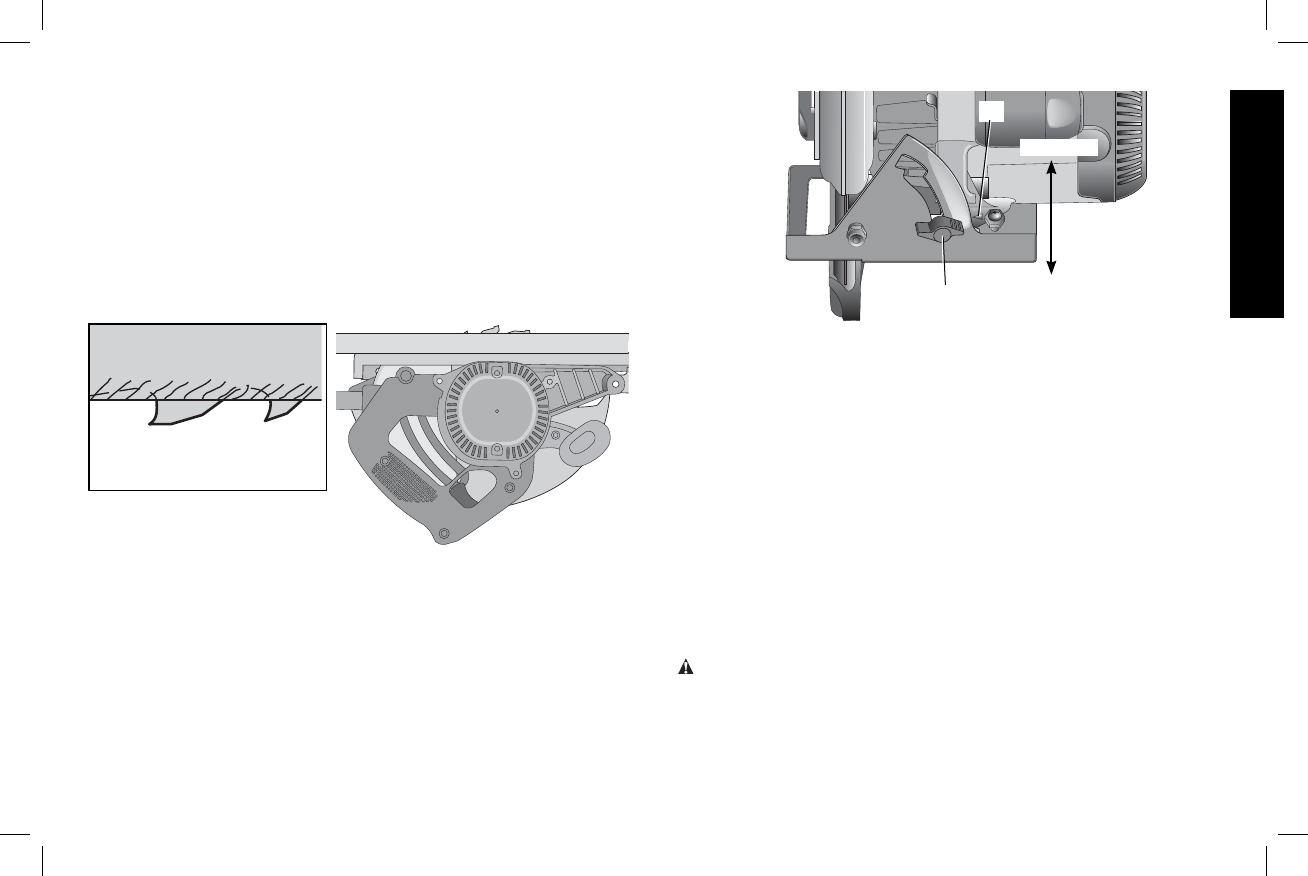

FIG. 8

C

L

TIGHTEN

LOOSEN

1. To set the saw for a bevel cut, turn the knob (C) to loosen the

bevel adjustment.

2. Tilt the shoe to the desired angle by aligning the pointer (L) with

the desired angle mark on the pivot bracket.

3. Retighten the bevel adjustment by turning the knob (C).

Bevel Detent (Fig. 8)

The saw has a bevel stop at 45º. To set the bevel at an angle greater

than 45º, tilt the shoe to 45º, then slide the knob (C) into the upper

slot. When you reach the desired angle, tighten the knob.

Kerf Indicator

The front of the saw shoe has a kerf indicator for vertical and bevel

cutting. This indicator enables you to guide the saw along cutting lines

penciled on the material being cut.

OPERATION

WARNING: To reduce the risk of serious personal injury,

turn tool off and disconnect tool from power source before

making any adjustments or removing/installing attachments or

accessories.

Your saw is equipped with a carbide tipped saw blade for long life and

efficient cutting.

Setting the saw at the proper cutting depth keeps blade friction to a

minimum, removes sawdust from between the blade teeth, results

in cooler, faster sawing and reduces the chance of kickback. Align

the appropriate mark on the depth adjustment strap with triangle

(K, Fig. 5) on the upper blade guard. Your depth is set.

For the most efficient cutting action using a carbide tipped saw blade,

set the depth adjustment so that about one half of a tooth projects

below the surface of the wood to be cut (Fig. 6).

FIG. 6

FIG. 7

A method of checking for the correct cutting depth is shown in

Figure 7. Lay a piece of the material you plan to cut along the side

of the blade, as shown in the figure, and observe how much tooth

projects beyond the material.

Bevel Angle Adjustment (Fig. 8)

The full range of bevel adjustment is from 0 to 50º. The pivot bracket

is graduated in increments of 1º.

On the front of the saw is a bevel angle adjustment mechanism

consisting of a quadrant with a pointer (L) and a knob (C).