66

Adjustments

WARNING: To reduce the risk of serious personal injury, turn off the

tool and disconnect it from the power source before attempting to move

it, change accessories or make any adjustments accept as written in laser

adjustment instructions.

NOTE: Your miter saw is fully and accurately adjusted at the factory at the

time of manufacture. If readjustment due to shipping and handling or any

other reason is required, follow the steps below to adjust your saw.

Once made, these adjustments should remain accurate. Take a little time

now to follow these directions carefully to maintain the accuracy of which

your saw is capable.

MITER SCALE ADJUSTMENT (FIG. 5)

Place a square against the saw’s fence and blade, as shown. (Do not

touch the tips of the blade teeth with the square. To do so will cause an

inaccurate measure ment.) Loosen the miter lock handle and swing the

miter arm until the miter latch locks it at the 0 miter position. Do not

tighten the lock handle. If the saw blade is not exactly

perpendicular to the fence, loosen the four screws that hold the miter

scale to the base and move the scale left or right until the blade is

perpendicular to the fence, as measured with the square. Retighten the

four screws. Pay no attention to the reading of the miter pointer at this

time.

MITER POINTER ADJUSTMENT (FIG. 6)

Loosen the miter lock handle to move the miter arm to the zero position.

With the miter lock handle loose allow the miter latch to snap into place

as you rotate the miter arm to zero. Observe the pointer and miter scale

shown in Figure 6. If the pointer does not indicate exactly zero, loosen the

screw holding the pointer in place, reposition the pointer and tighten the

screw.

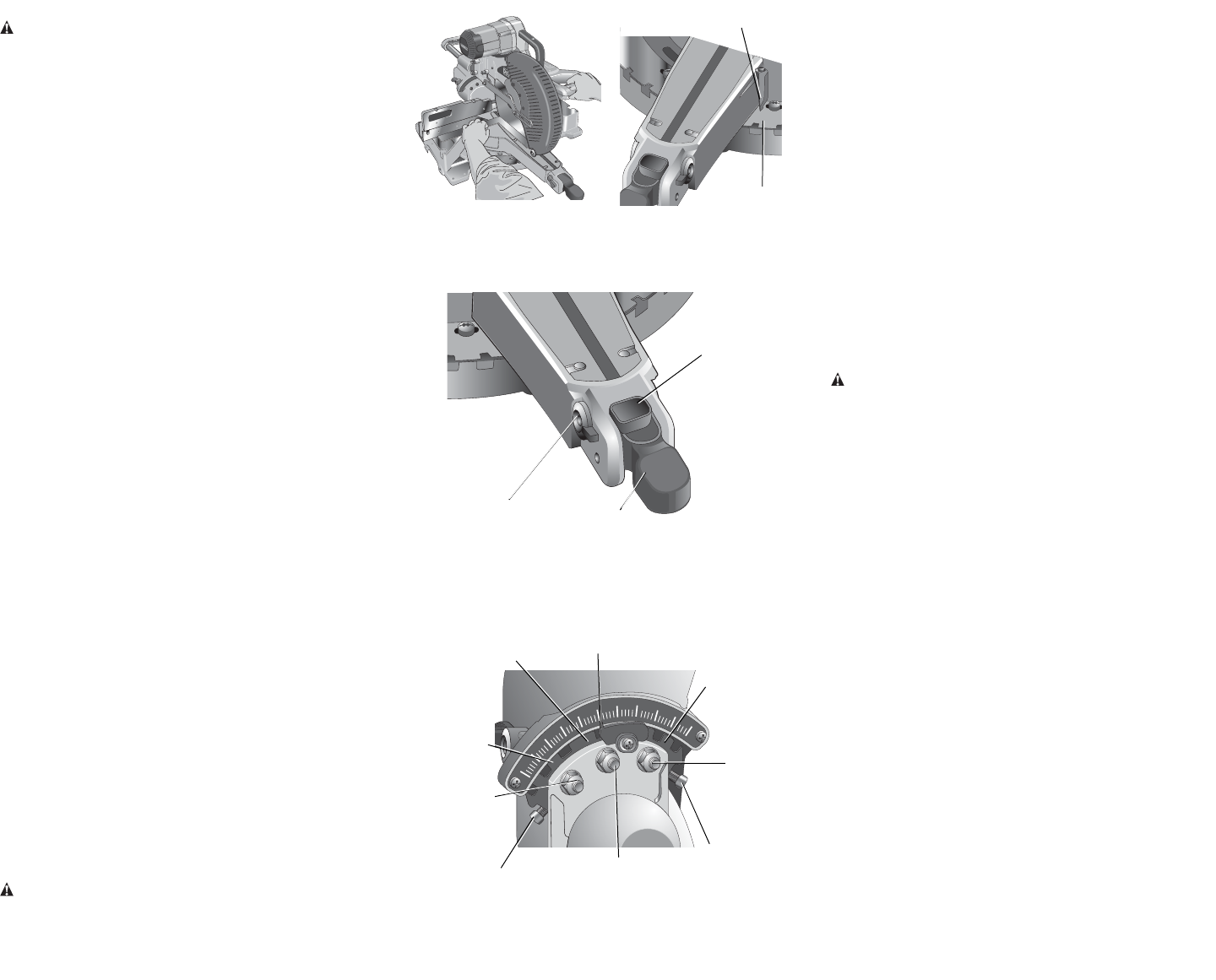

BEVEL SQUARE TO TABLE ADJUSTMENT (FIG. 8)

To align the blade square to the table, lock the arm in the down position.

Place a square against the blade and table taking care to have the square

not touch a blade tooth. Loosen the bevel lock handle and ensure the

bevel latch has firmly snapped into place at 0º. If the saw blade is not

exactly perpendicular to the table, loosen the three nuts which hold the

bevel detent plates to the table. Adjust the center nut to allow slight drag

between it and the table. Gently tap the motor or the belt cover to move

the upper assembly until the blade is square to the table. Tighten the

center nut. The 45º bevel stops require adjustment after the bevel square

to table adjustment is complete.

BEVEL POINTER (FIG. 8)

If the bevel pointer does not indicate zero, loosen the screw that holds it in

place and move it as necessary.

BEVEL STOP 45º RIGHT AND LEFT ADJUSTMENT (FIG. 8)

Your saw has two 45º bevel adjustments, one for the right, and one for

the left. The procedure is the same for each.

To align the 45º stops, lock the arm in the down position. Place a speed

square against the blade and table taking care to have the square not

touch a blade tooth. Loosen the bevel lock lever and ensure the bevel

latch has firmly snapped into place at 45º. If the saw blade is not 45º

to the table, loosen the nut which holds the 45 bevel latch plate to the

table. Rotate the adjustment screw counterclockwise one or two turns

so that the blade is less than 45º to the table. Turn the adjustment screw

clockwise until the blade is 45º to the table. Tighten the lock nut.

FENCE ADJUSTMENT (FIG. 9)

WARNING: To reduce the risk of serious personal injury, turn off the

tool and disconnect it from the power source before attempting to move

it, change accessories or make any adjustments accept as written in laser

adjustment instructions.

In order that the saw can bevel to a full 48º left or right, one of the fences

can be adjusted to provide clearance. To adjust the fences, loosen a

plastic knob and slide the fence outward. Make a dry run with the saw

turned off and check for clearance. Adjust the fence to be as close to

the blade as practical to provide max imum workpiece support, without

interfering with arm up and down movement. Tighten knob securely. When

the bevel operations are complete, don’t forget to relocate the fence.

NOTE: The guide groove of the fences can become clogged with sawdust.

If you notice that it is becoming clogged, use a stick or some low

pressure air to clear the guide groove.

AUTOMATIC ELECTRIC BRAKE

Your saw is equipped with an automatic electric blade brake which stops

the saw blade within 5 seconds of trigger release. This is not adjustable.

On occasion, there may be a delay after trigger release to brake

engagement. On rare occasions, the brake may not engage at all and the

blade will coast to a stop.

If a delay or “skipping” occurs, turn the saw on and off 4 or 5 times. If

the condition persists, have the tool serviced by an authorized D

EWALT

service center.

Always be sure the blade has stopped before removing it from the kerf.

The brake is not a substitute for guards or for ensuring your own safety by

giving the saw your complete attention.

GUARD ACTUATION AND VISIBILITY

CAUTION: Risk of personal injury. Keep thumb underneath handle when

pulling handle down otherwise thumb may be pinched between handle

and moving lower guard. The handle is placed close to the guard for

special cuts.

The blade guard on your saw has been designed to automatically raise

when the arm is brought down and to lower over the blade when the arm

is raised.

The guard can be raised by hand when installing or removing saw

blades or for inspection of the saw. NEVER RAISE THE BLADE GUARD

MANUALLY UN LESS THE SAW IS TURNED OFF.

NOTE: Certain special cuts of large material will require that you manually

raise the guard. See page 11.

The front section of the guard is louvered for visibility while cutting.

Although the louvers dramatically reduce flying debris, they are openings

in the guard and safety glasses should be worn at all times when viewing

through the louvers.

KERF PLATE ADJUSTMENT

To adjust the kerf plates, loosen the screws holding the kerf plates in

place. Adjust so that the kerf plates are as close as possible without

interfering with the blade’s movement.

RAIL GUIDE ADJUSTMENT

Periodically check the rails for any play or clearance. The right rail can be

adjusted with the set screw shown in Figure 4. To reduce clearance, use

a 4 mm hex wrench and rotate the set screw clockwise gradually while

sliding the saw head back and forth. Adjust the clearance to be as small

as possible without causing any slide resistance.

MITER LOCK ADJUSTMENT

The miter lock rod should be adjusted if the table of the saw can be

moved when the miter lock is locked down. To adjust the miter lock

handle, put the miter lock handle in the up, unlocked position. Using a

13 mm open end wrench, loosen the lock nut on the miter lock rod

(Fig. 10A). Using a slotted screwdriver, tighten the miter lock rod by

turning it clockwise as shown in Figure 10A. Turn the lock rod until it

is snug, then turn counterclockwise one turn. To ensure the miter lock

FIG. 6

MITER

SCALE

MITER

POINTER

FIG. 5

FIG. 8

RIGHT 45º BEVEL

LATCH PLATE

LEFT 45º BEVEL

LATCH PLATE

RIGHT 45º

BEVEL PLATE

LOCK NUT

BEVEL POINTER

LEFT 45º BEVEL

ADJUSTMENT

SCREW

RIGHT 45º BEVEL

ADJUSTMENT SCREW

0º BEVEL LOCK

NUT

0º BEVEL LATCH PLATE

LEFT 45º

BEVEL PLATE

LOCK NUT

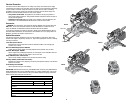

FIG. 7

MITER LOCK

HANDLE

MITER LATCH

BUTTON

MITER LATCH

OVERRIDE