7

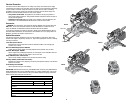

when the bevel lock handle is tightened. To adjust the bevel lock handle,

remove the screw in the center of the handle. Carefully pry off the handle

using a flat bladed screwdriver. Reorient and install the handle such that it

will hold the bevel when tightened. Install and tighten screw.

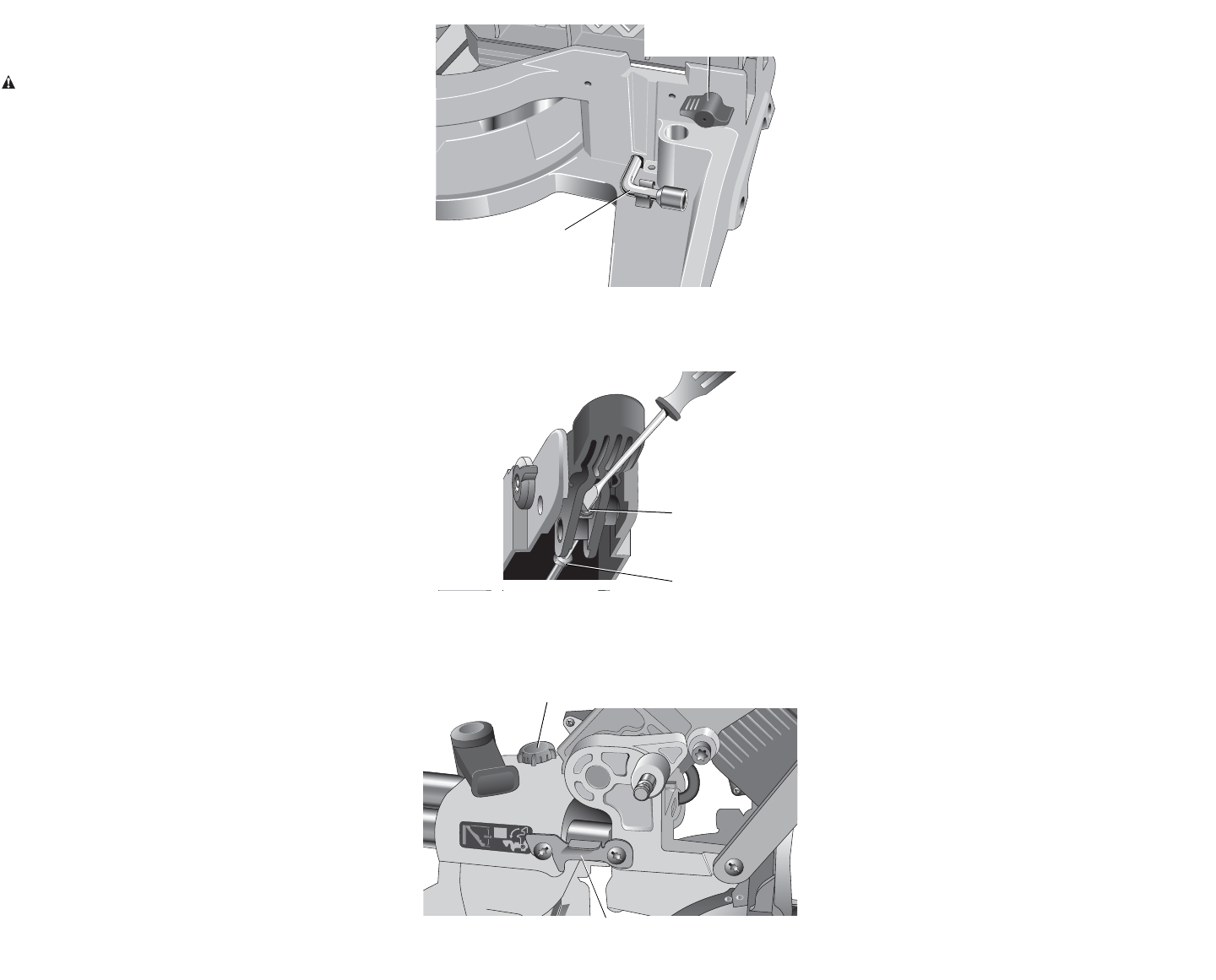

SLIDE STOP (FIG. 10B)

The slide stop control positions your saws rails so that the largest

possible verticle moldings can be cut. ALWAYS TIGHTEN THE RAIL LOCK

KNOB WHEN USING THE SLIDE STOP TO PREVENT THE SLIDE SYSTEM

FROM MOVING UNINTENTIONALLY

RAIL LOCK KNOB (FIG. 4)

The rail lock knob allows you to lock the saw head firmly to keep it from

sliding on the rails. This is necessary when making certain cuts or when

transporting the saw.

GROOVING STOP (FIG. 4)

The grooving stop allows for groove cutting. Flipping the lever toward the

front of the saw and adjusting the thumbscrew changes the depth of the

groove cut. Flipping the lever toward the rear of the saw bypasses the

grooving stop.

HEAD LOCK-DOWN PIN (FIG. 4)

To lock the saw head in the down position, push the head down, push the

pin in and release the saw head. This will hold the saw head safely down

for moving the saw from place to place. To release, press the saw head

down and pull the pin out.

Operation

Plug the saw into any household 50 Hz power source. Refer to the

nameplate for voltage. Be sure the cord will not interfere with your work.

SWITCH

To turn the saw on, depress the trigger switch. To turn the tool off,

release the switch. Allow the blade to spin up to full operating rpm before

making the cut. Release the trigger switch and allow the brake to stop the

blade before raising the saw head. There is no provision for locking the

switch on, but a hole is provided in the trigger for insertion of a padlock

to lock the saw off.

CUTTING WITH YOUR SAW

If the slide feature is not used, ensure the saw head is pushed back as far

as possible and the rail lock knob is tightened. This will prevent the saw

from sliding along its rails as the workpiece is engaged.

NOTE: Although this saw will cut wood and many non-ferrous materials,

we will limit our discussion to the cutting of wood only. The same

guidelines apply to the other mat erials. DO NOT CUT FERROUS (IRON

AND STEEL) MAT ERIALS OR MASONRY WITH THIS SAW. Do not use

any abrasive blades.

CROSSCUTS

Cutting of multiple pieces is not recommended but can be done safely by

ensuring that each piece is held firmly against the table and fence. When

the saw comes up to speed (about 1 second) lower the arm smoothly and

slowly to cut through the wood. Let the blade come to a full stop before

raising arm.

A crosscut is made by cutting wood across the grain at any angle. A straight

crosscut is made with the miter arm at the zero degree position. Set and

lock the miter arm at zero, hold the wood firmly on the table and against the

fence. With the rail lock knob tightened, turn on the saw by squeezing the

trigger switch shown in Figure 4.

When the saw comes up to speed (about 1 second) lower the arm smoothly

and slowly to cut through the wood. Let the blade come to a full stop before

raising arm.

7

handle is functioning properly, re-lock the miter lock to a non-detented

measurement on the miter scale – for example, 34º – and ensure the

table will not rotate. Tighten lock nut.

Brushes

WARNING: To reduce the risk of serious personal injury, turn off the

tool and disconnect it from the power source before attempting to move

it, change accessories or make any adjustments accept as written in

laser adjustment instructions.

Inspect carbon brushes regularly by unplugging tool, removing the motor

end cap (Fig. 4), lift the brush spring and withdraw the brush assembly.

Keep brushes clean and sliding freely in their guides. Always replace

a used brush in the same orientation in the holder as it was prior to its

removal. Carbon brushes have varying symbols stamped into their sides,

and if the brush is worn down to approximately 12.7 mm (1/2"), the

spring will no longer exert pressure and they must be replaced. Use only

identical D

EWALT brushes. Use of the correct grade of brush is essential

for proper operation of electric brake. New brush assemblies are available

at DEWALT service centers. The tool should be allowed to “run in” (run

at no load) for 10 minutes before use to seat new brushes. The electric

brake may be erratic in operation until the brushes are properly seated

(worn in). Always replace the brush inspection cap after inspection or

servicing the brushes.

While “running in” DO NOT TIE, TAPE, OR OTHER WISE LOCK THE

TRIGGER SWITCH ON. HOLD BY HAND ONLY.

Controls

Your compound miter saw has several main controls, which will be

discussed briefly here. For more information on these controls, see the

respective sections earlier in the manual.

MITER CONTROL (FIG. 7)

The miter adjustment/lock handle and detent trigger allows you to

miter your saw to 60 left and 50 right. To miter the saw, lift the miter

adjustment/lock handle, push the miter latch button and set the miter

angle desired on the miter scale. Push down on the lock handle to lock

the saw table in place.

TRIGGER SWITCH

The trigger switch (Fig. 4) turns your saw on and off. A hole is provided

in the trigger for insertion of a padlock to secure the saw.

MITER LATCH OVERRIDE (FIG. 7)

The miter latch override allows your saw to override the common stop

angles. Your saw has two miter latch override knobs, one on each side

of the miter control. To override the common stop angles, rotate the

miter latch knobs downward. The knobs will return to the off position

automatically if the miter latch button is pushed.

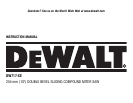

BEVEL CONTROL (FIG. 8)

The bevel latch levers and bevel lock handle allow you to bevel the saw to

48º left and right. Your saw has two bevel latch levers, one on either side

of the rear support housing. Only one needs to be used to move the bevel

to either direction. The bevel lock handle is on top of the rear support

housing. To bevel the saw, loosen the bevel lock handle. Lift one of the

levers to approximately 45 º and set the bevel angle desired on the bevel

scale. Two bevel scales are provided for convenience. Lock the bevel

lock handle to lock the bevel in place. The bevel latch levers can be lifted

vertically to override the common stop angles.

The bevel lock handle is designed to have a limited rotation amount. The

handle can be reoriented to compensate for normal wear. The bevel

lock handle should be reoriented if the bevel of the saw can be moved

FIG. 9

LEFT-SIDE

FENCE KNOB

BLADE WRENCH

FIG. 10A

MITER LOCK ROD

LOCK NUT

FIG. 10B

SLIDE STOP

RAIL LOCK KNOB