Page 15

Maintenance

Service

Preventive maintenance

performed by unauthorized

personnel may result in misplacing of internal wires

and components which could cause serious hazard.

We recommend that all tool service be performed by a

Dremel Service Facility.

CARBON BRUSHES

The brushes and commutator in your tool have been

engineered for many hours of dependable service. To

maintain peak efficiency of the motor, we recommend

every two to six months the brushes be examined. Only

genuine Dremel replacement brushes specially

designed for your tool should be used.

MAINTENANCE OF REPLACEABLE BRUSHES

MODEL 398-49

The brushes should be inspected frequently when

tools are used continuously. If your tool runs sporad-

ically, loses power, makes unusual noises or runs at a

reduced speed, check the brushes. To continue using

the tool in this condition will permanently damage

your tool.

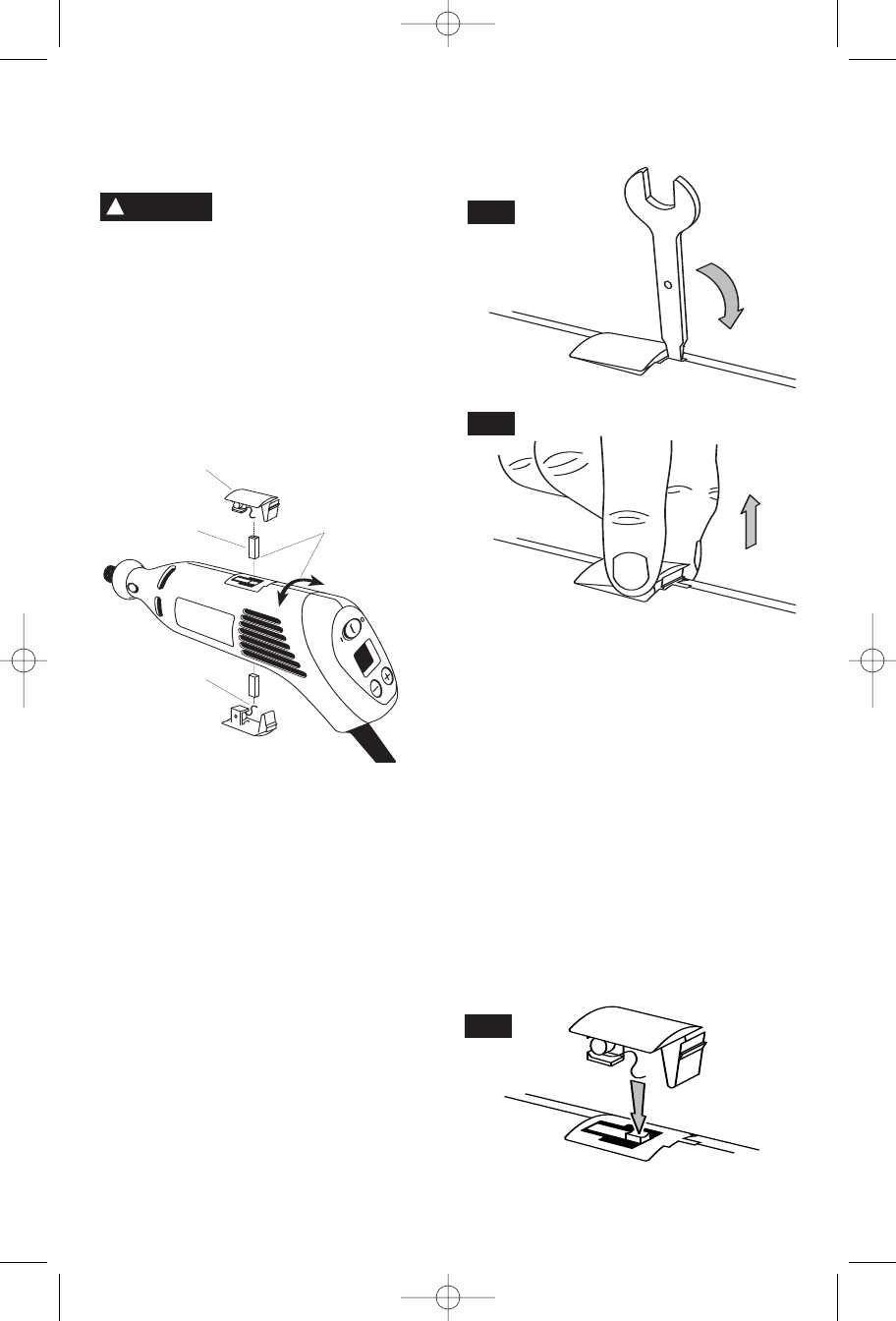

To Remove Brush Door

Disconnect the tool from the power supply. Each

brush door is held in place by a snap latch. To

disengage latch, place screwdriver end of wrench

(included) in slot at rear of door and pry up as

shown in Figure 1. With latch disengaged, using a

little force, pull up rear of door and lift away brush

door and spring assembly from housing, Figure 2.

Check Both Brushes

Turn tool so the brush falls out of holder and check

each brush. If the brush is less than 3,2mm long and

the end surface of the brush that contacts the

commutator is rough and/or pitted, they should be

replaced. Check both brushes. Usually the brushes will

not wear out simultaneously. If one brush is worn out,

replace both brushes. Make sure the brushes are

installed as illustrated. The curved surface of the

brush must match the curvature of the commutator.

To Replace Brush Door

Rest squared underside of brush door on the

squared cavity openings. Check to be sure the spring

rests on the V groove of the brush, Figure 3. Push

front of door down into the slot, Figure 4, then push

down and snap the rear latch into it’s slot, Figure 5.

After replacing brushes the tool should be run at no-

load; place it on a clean surface and run it freely for 5

BRUSH

DOOR

BRUSH

SPRING

CURVED END OF

BRUSH MUST

MATCH CURVATURE

OF HOUSING

BRUSH

WARNING

!

FIG. 1

FIG. 2

FIG. 3

Any Questions Call

03-5415317

DM 2610934164 05-06 10/6/06 8:41 AM Page 15