Page 7

Assembly - (cont.)

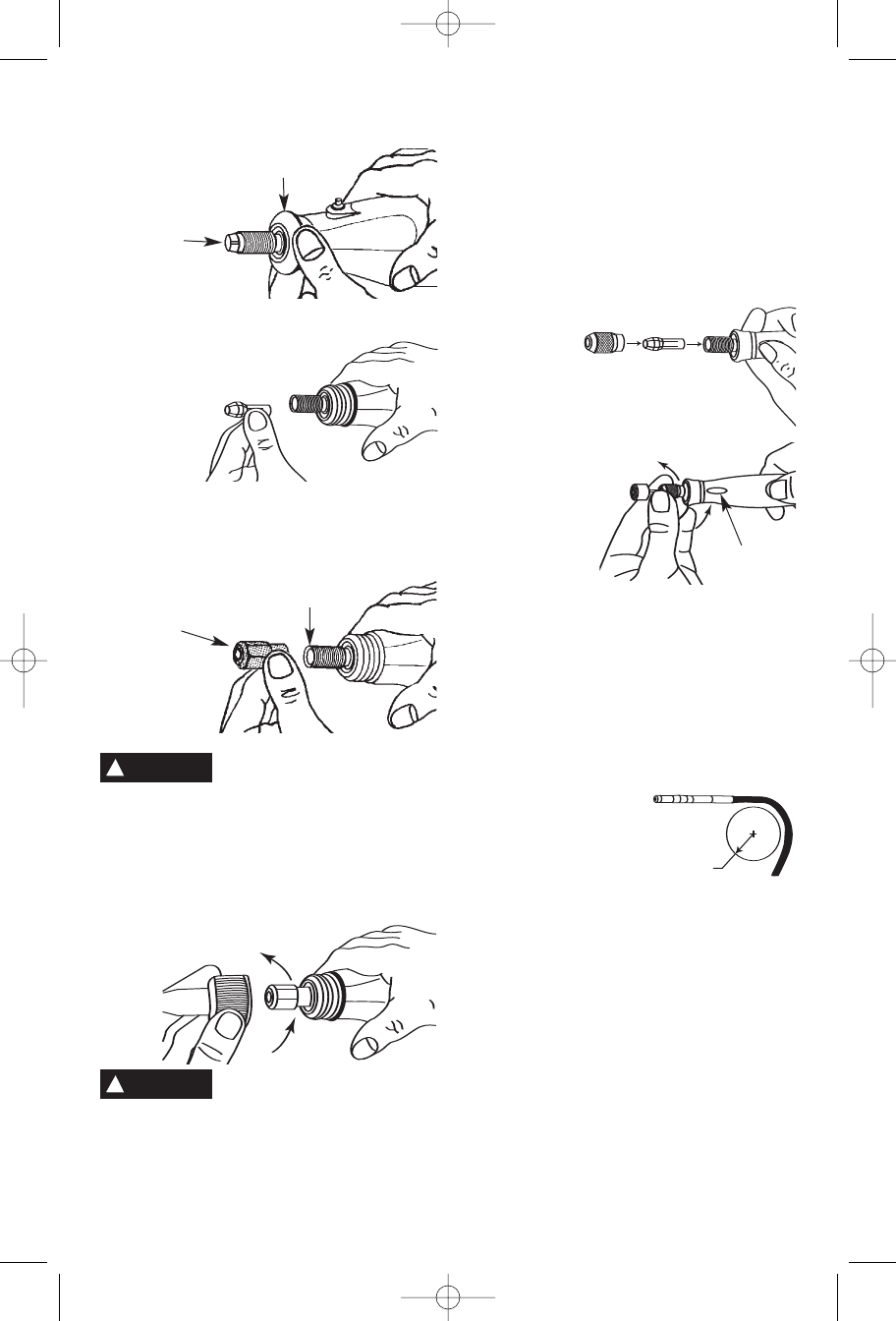

Step 3. Remove the collet.

Note: If the collet nut and collet are not removed from

the motor shaft, the tool will not function properly.

Step 4. Install the driver cap on the motor shaft and

tighten.

To prevent damage to tool, do not

overtighten driver cap. Tighten

the driver cap finger tight and then tighten an

additional 1/3 turn with the wrench. (Wrench included

with your rotary tool kit)

Step 5. Attach by screwing the collar of the flex-shaft

to the rotary tool. Make sure the square end of the

center core engages the square hole socket in the

driver cap.

Do not pull out center core to

engage into driver cap. This

could cause disengagement of center core from

handpiece. If tool stops when shaft is bent, center

core may be lodged in driver cap. Loosen shaft and

remove core from driver cap. Then screw flexible

shaft onto rotary tool housing again.

Disengagement of the Flex-Shaft

The flexible shaft may become disengaged if the

motor of your rotary tool is not elevated higher than

the working end of the flex-shaft. The #2222 Rotary

Tool Stand is recommended to hold the rotary tool at

the proper height.

Collet and Accessory Assembly

The collet assembly consists of a collet nut and collet.

Take the collet nut

and collet that

were removed

from your tool in

step 2 and 3 and

insert them into

the tip of the flex-

shaft handpiece.

Insert an accessory or

bit as deeply as

possible to avoid

wobble during use.

With the shaft lock

button engaged on the

flex-shaft handpiece

retighten the collet nut.

Collet Removal and Replacement

Four different size collets to accommodate different

shank sizes, are sold separately for your flex-shaft. To

install a different collet, remove the collet nut and

remove the old collet. Insert the unslotted end of the

collet in the hole in the end of the flex-shaft. Replace

collet nut on the shaft. Always use the collet which

matches the shank size of the accessory you plan to

use. Never force a larger diameter shank into a

collet.

Do not operate the

flexible shaft with a

sharp or multiple

bends. Over bending

the shaft can generate

excessive heat on the

jacket or hand piece

and may cause the flexible shaft to disengage from

tool. The minimum recommended bend radius is 13cm.

Flexible Shaft Lubrication

The flex-shaft should be lubricated after every 25-30

hours of use. To lubricate, unscrew the flex-shaft

assembly from the motor housing. Pull the center

core out of the flex-shaft assembly. Wipe a very thin

film automotive wheel bearing grease on to the center

core and reinsert it back into the shaft. To prevent

damage to tool do not over grease shaft. Too much

grease will cause the unit to overheat.

Reattach the flex-shaft to the rotary tool.

Contents of 225 Flex-Shaft Attachment

Qty. Description

1 Flex-Shaft Assembly (1,07m long)

1 Driver Cap

!

CAUTION

DRIVER

CAP

MOTOR

SHAFT

H

OUSING

C

AP

C

OLLET

(

inside)

SHAFT LOCK

BUTTON

!

CAUTION

13CM

RADIUS

DM 2610934164 05-06 10/6/06 8:41 AM Page 7