Page 18

Wire Brushes

Three different shapes of wire brushes are available.

Never use wire brushes at speeds greater than

15.000 RPM. Refer to Operating Speeds section for

proper tool speed setting. The three shapes come in

three different materials: stainless steel, brass and

carbon wire. The stainless steel perform well on

pewter, aluminum, stainless steel, and other metals,

without leaving "after-rust". Brass brushes are non

sparking, and softer than steel; making them good for

use on soft metal like gold, cooper and brass. The

carbon wire brushes are good for general purpose

cleaning.

Bristle Brushes

These are excellent cleaning tools on silverware, jew-

elry and antiques. The three shapes make it possible to

get into tight corners and other difficult places. Bristle

brushes can be used with polishing compound for

faster cleaning or polishing.

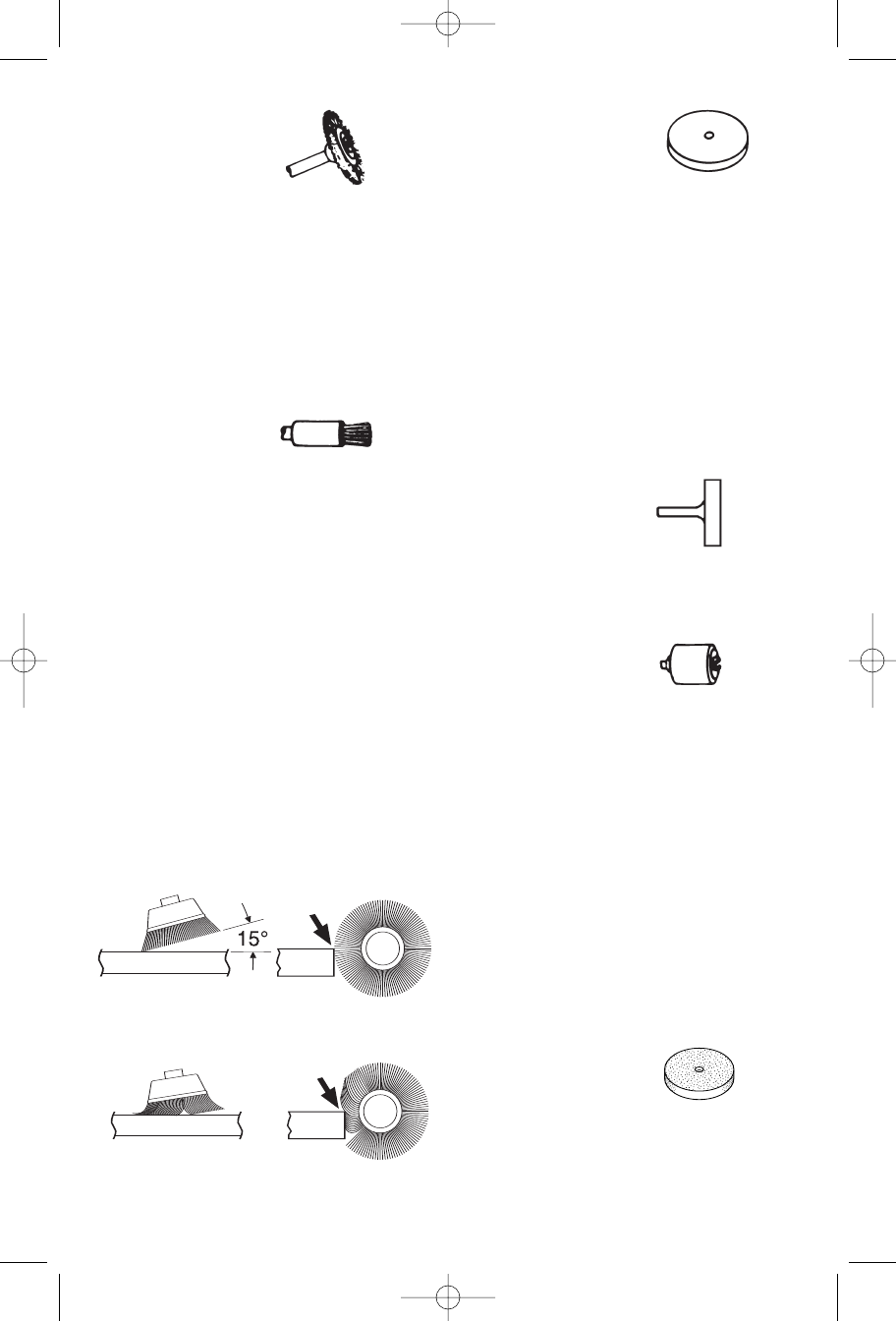

Brushing Pressure

1. Remember, the tips of a wire brush do the work.

Operate the brush with the lightest pressure so only

the tips of the wire come in contact with the work.

2. If heavier pressures are used, the wires will be

overstressed, resulting in a wiping action; and if this

is continued, the life of the brush will be shortened

due to wire fatigue.

3. Apply the brush to the work in such a way that as

much of the brush face as possible is in full contact

with the work. Applying the side or edge of the brush

to the work will result in wire breakage and shortened

brush life.

P

olishing Accessories

These include an impregnated polishing point and an

impregnated polishing wheel for bringing metal sur-

faces to smooth finish; a felt polishing tip and felt

polishing wheel, and cloth polishing wheel, all used for

polishing plastics, metals, jewelry and small parts. Also

included in this group is a polishing compound (No.

421) for use with the felt and cloth polishers.

Polishing points make a very smooth surface, but a

high luster is obtained using felt or cloth wheels and

polishing compound. For best results polishing

accessories should be used at speeds not greater

than 15.000 RPM. Refer to Operating Speeds section

for proper tool speed setting.

No polishing compound is needed when using the

425 Polishing Wheel or 427 Polishing point.

Aluminum Oxide Abrasive Wheels

Use to remove paint, deburr metal, polish stainless

steel and other metals. Available in fine and medium

grits. 3,2mm shank.

Sanding Accessories

Sanding discs in fine, medium and coarse grades are

made to fit mandrel No. 402. They can be used for

nearly any small sanding job you might have, from

model making to fine furniture finishing. In addition,

there is the drum sander, a tiny drum which fits into the

Rotary Tool and makes it possible to shape wood,

smooth fiberglass, sand inside curves and other diffi-

cult places, and other sanding jobs. You replace the

sanding bands on the drum as they become worn and

lose their grit. Bands come in fine and coarse grades.

Flapwheels grind and polish flat or contoured surfaces.

They are used most effectively as a finishing sander

after heavier surface sanding and material removal is

completed. Flapwheels come in fine and coarse grades.

Buffs are a great finishing accessor

y for cleaning and

light sanding. They work effectively on metal, glass,

wood, aluminum and plastics. Coarse and medium

buffs are sold together

. 3,2mm shank.

Grinding Wheel

Use for deburring, removing rust, and general purpose

grinding. Use with Mandrel #402.

CORRECT:

Wire tips doing the work.

INCORRECT:

Excessive pressure can cause wire breakage.

DM 2610934164 05-06 10/6/06 8:41 AM Page 18