12

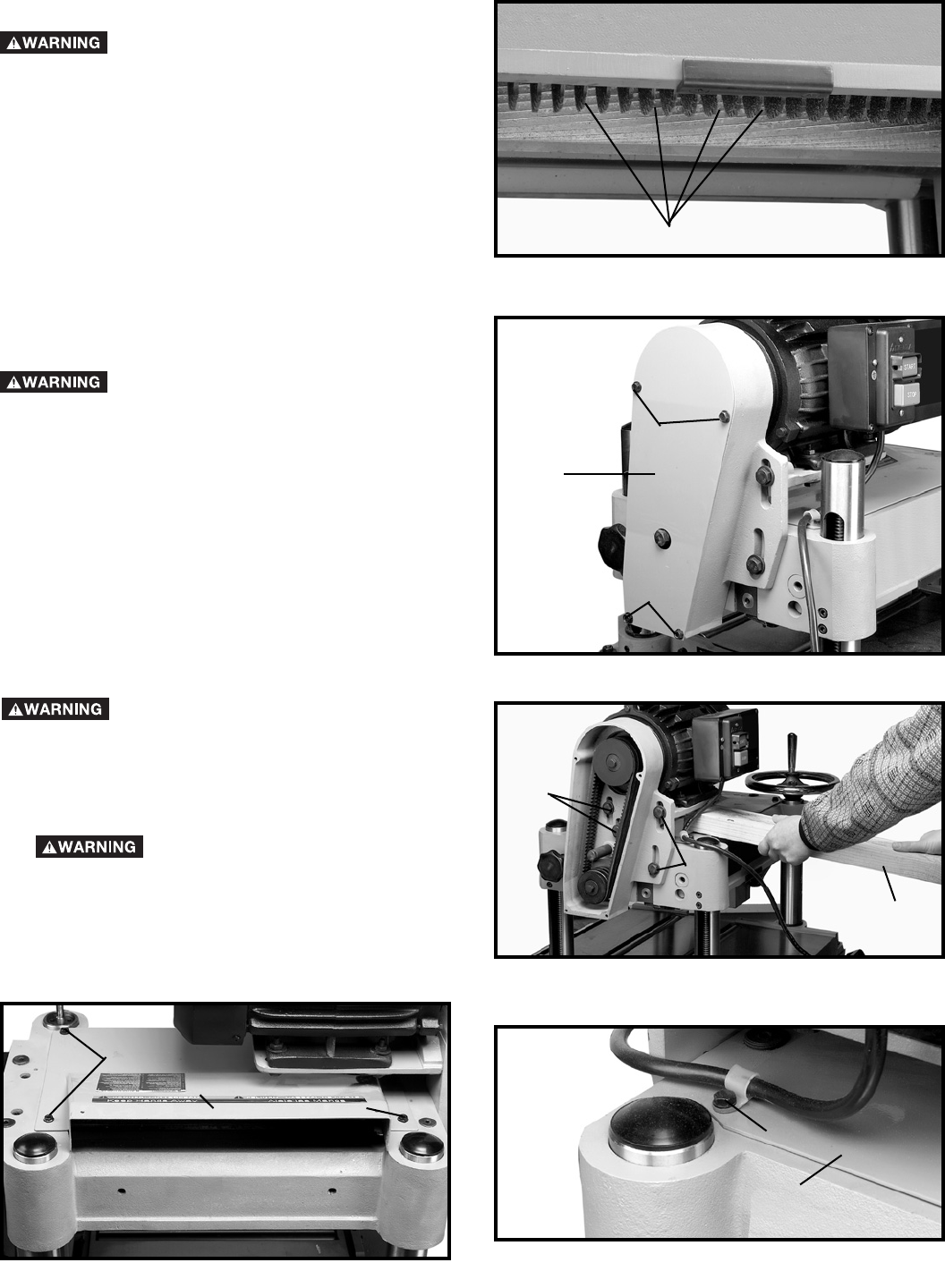

ANTI-KICKBACK FINGERS

WHEN INSPECTING AND CLEANING

THE ANTI-KICKBACK FINGERS, MAKE

SURE THE MACHINE IS DISCONNECTED FROM THE

POWER SOURCE.

A series of anti-kickback fingers (A) Fig. 27, are provided

on the infeed end of the planer, to prevent kickback of

the workpiece during the planing operation. These anti-

kickback fingers operate by gravity and no adjustment is

required. It is necessary, however, to inspect them

occasionally to make sure they are free of gum and pitch

and that they move independently and operate correctly.

Fig. 27

ADJUSTING

BELT TENSION

DISCONNECT MACHINE FROM POWER

SOURCE.

1. Remove four screws (A) Fig. 28, and remove the belt

and pulley guard cover (B).

2. Place a 2 x 4 (D) Fig. 29, between the motor plate

and the top of the head casting as shown.

3. Loosen the four screws (C) Fig. 29, and pry up on

motor plate until correct belt tension is obtained. Correct

tension is when there is approximately 1/4" deflection in

the center span of the belts using light finger pressure.

Then tighten the three screws (C) and replace belt and

pulley guard cover (B) Fig. 28.

Fig. 28

Fig. 29

B

A

A

A

D

C

C

Fig. 30

Fig. 31

A

B

A

A

B

CHECKING, ADJUSTING AND

REPLACING KNIVES

IF THE KNIVES ARE TO BE REMOVED

FOR SHARPENING OR REPLACE-

MENT, EXTREME CARE SHOULD BE TAKEN AS THE

KNIVES ARE VERY SHARP. TO REMOVE THE

KNIVES, WEAR GLOVES AND PROCEED AS

FOLLOWS:

1. DISCONNECT MACHINE FROM

POWER SOURCE.

2. Remove four screws (A) Fig. 30 and Fig. 31, and

remove top cover (B).

3. Loosen two screws (C) Fig. 32, and pivot motor as-

sembly (D) to the front. NOTE: Belt tension is not

disturbed when pivoting the motor forward.