18

ENGLISH

• Always keep sufficient distance to

the saw blade. Use suitable feeding

aids, if necessary. Keep sufficient

distance to driven components

when the operating electric tool.

• Wait for the saw blade to come to a

complete stop before removing cut-

offs, scrap, etc. from the work area.

• Do not attempt to stop the saw

blade by pushing the workpiece

against its side.

• Ensure the tool is disconnected from

power before servicing.

• Ensure that when switching on (e.g.

after servicing) no tools or loose

parts are left on or in the tool.

• Turn power off if the tool is not used.

A

Cutting hazard, even with the

cutting tool at standstill!

• Wear gloves when changing cutting

tools.

• Store saw blade in such manner that

nobody will get hurt.

A

Risk of kickback (workpiece is

caught by the saw blade and thrown

against the operator):

• Always work with a properly set riv-

ing knife.

• Do not jam workpieces.

• Make sure the saw blade is suitable

for the workpiece material.

• Cut thin or thin-walled workpieces

only with fine-toothed saw blades.

• Always use sharp saw blades.

• If in doubt, check workpiece for

inclusion of foreign matter (e.g. nails

or screws).

• Cut only stock of dimensions that

allow for safe and secure holding

while cutting.

• Never cut several workpieces at the

same time – and also no bundles

containing several individual pieces.

Risk of personal injury if individual

pieces are caught by the saw blade

uncontrolled.

• Remove small cutoffs, scrap, etc.

from the work area – when doing so

the saw blade must be at a com-

plete standstill.

C

Drawing-in/trapping hazard!

• Ensure that no parts of the body or

clothing can be caught and drawn in

by rotating components (no neck-

ties, no gloves, no loose-fitting

clothes; contain long hair with hair-

net).

• Never attempt to cut any workpieces

which contain

− ropes,

− strings,

− cords,

− cables or

− wires, or to which any of the

above are attached.

A

Hazard generated by insuffi-

cient personal protection gear!

• Wear hearing protection.

• Wear safety glasses.

• Wear dust mask.

• Wear suitable work clothes.

• When working outdoors wearing of

non-slip shoes is recommended.

A

Risk of injury by inhaled wood

dust!

• Dust of certain timber species (e.g.

beech, oak, ash) can cause cancer

when inhaled. Work only with a suit-

able dust collector attached to the

saw. The dust collector must comply

with the data stated in the technical

specifications.

• Ensure that as little as possible

wood dust will get into the environ-

ment:

− remove wood dust deposit in the

work area (do not blow away!);

− fix any leakages on the dust col-

lector;

− ensure good ventilation.

A

Hazard generated by modifica-

tion of the machine or use of parts

not tested and approved by the equip-

ment manufacturer!

• Assemble tool in strict accordance

with these instructions.

• Use only parts approved by the

equipment manufacturer. This

applies especially for:

− saw blades (see "Technical spec-

ifications" for stock nos.);

− safety devices (see "Technical

specifications" for stock nos.).

• Do not change any parts.

A

Hazard generated by tool

defects!

• Keep tool and accessories in good

repair. Observe the maintenance

instructions.

• Before every use check tool for pos-

sible damage: before operating the

tool all safety devices, protective

guards or slightly damaged parts

need to be checked for proper func-

tion as specified. Check to see that

all moving parts work properly and

do not jam. All parts must be cor-

rectly installed and meet all condi-

tions necessary for the proper oper-

ation of the tool.

• Damaged protection devices or

parts must be repaired or replaced

by a qualified specialist. Have dam-

aged switches replaced by a service

centre. Do not operate tool if the

switch cannot be turned ON or OFF.

• Keep handles free of oil and grease.

A

Risk of injury by noise!

• Wear hearing protection.

• Make sure the riving knife is not

bend. A bent riving knife will push

the workpiece against the side of the

saw blade, causing noise.

4.3 Symbols on the machine

Information on the nameplate:

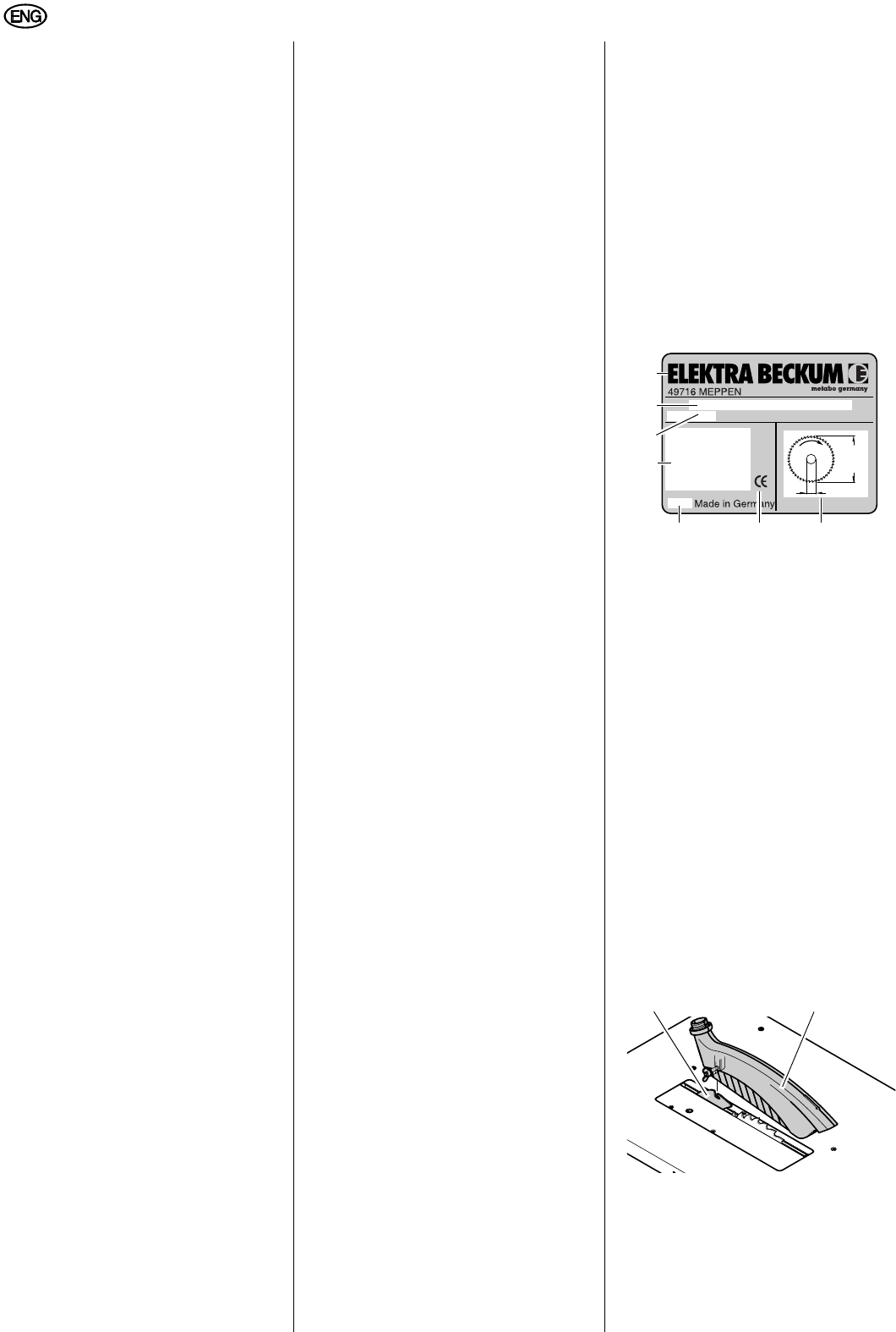

4.4 Safety devices

Riving knife

The riving knife (39) prevents the work-

piece from being caught by the rising

teeth of the saw blade and being thrown

against the operator.

Always have the riving knife installed

during operation.

Blade guard

The blade guard (40) protects against

unintentional contact with the saw blade

and from chips flying about.

Always have blade guard installed dur-

ing operation.

(32) Manufacturer

(33) Serial number

(34) Machine designation

(35) Motor specifications (see also

"Technical specifications")

(36) Year of make

(37) CE-mark – This machine con-

forms to the EC directives as per

Declaration of Conformity

(38) Dimensions of permissible saw

blades

33

34

35

36 37 38

32

39 40