21

ENGLISH

Position power supply cable so it

does not interfere with the work and

is not damaged.

Protect power supply cable from heat,

aggressive liquids and sharp edges.

Use only rubber jacketed cable of suf-

ficient lead cross section.

Do not pull on power supply cable to

unplug.

A

Changing the direction of rota

tion (3-phase motor only):

Depending on phase sequence the

band saw blade may turn in the wrong

direction. This can cause the work-

piece being tossed away when

attempting to cut. Therefore, always

check direction of rotation after every

connection to the power supply.

If the direction of rotation is incorrect,

the electrical connection must be

changed by a qualified electrician!

1. When the saw is assembled and all

safety devices are installed, connect

it to the power supply.

2. Start saw briefly and turn OFF

immediately again.

3. Check the band saw blade's direc-

tion of rotation: in the cutting area

it must run from the top down-

wards.

4. If the band saw blade turns in the

wrong correction, unplug the power

supply cable at the saw.

5. Have the electrical connection

changed by a qualified electrician!

A

Danger!

To reduce the risk of personal

injury as much as possible, the fol-

lowing safety recommendations

should be observed when operating

the saw.

Use personal protection gear:

− dust respirator;

− hearing protection;

− safety goggles.

Cut only one workpiece at a time.

Always hold the workpiece down on

the table.

Do not jam the workpiece.

Do not attempt to stop the band saw

blade by pushing the workpiece

against its side.

If the type of work requires, use the

following:

− push stick – if distance rip fence

– band saw blade ≤ 120 mm;

− work support – for long stock,

which would otherwise fall off the

table on completion of the cut;

− dust collector;

− an appropriate jig when cutting

round stock, to keep it from turn-

ing;

− a suitable guide for firm support

when cutting thin stock layed on

edge.

Before starting work, check to see

that the following are in proper work-

ing order:

− band saw blade;

− upper and lower blade guard.

Replace damaged parts immediately.

Assume correct work position (the

band saw blade's teeth must point

towards the operator).

Never cut several workpieces at the

same time – and also no bundles con-

taining several individual pieces. Risk

of personal injury if individual pieces

are caught by the saw blade uncon-

trolled.

c

Drawing-in/trapping hazard!

Do not wear loose clothing,

jewellery, or gloves, which may get

caught and wound up by revolving

machine parts.

Contain long hair with a hairnet.

Never cut stock to which ropes,

cords, strings, cables and wires are

attached or which contain such mate-

rials.

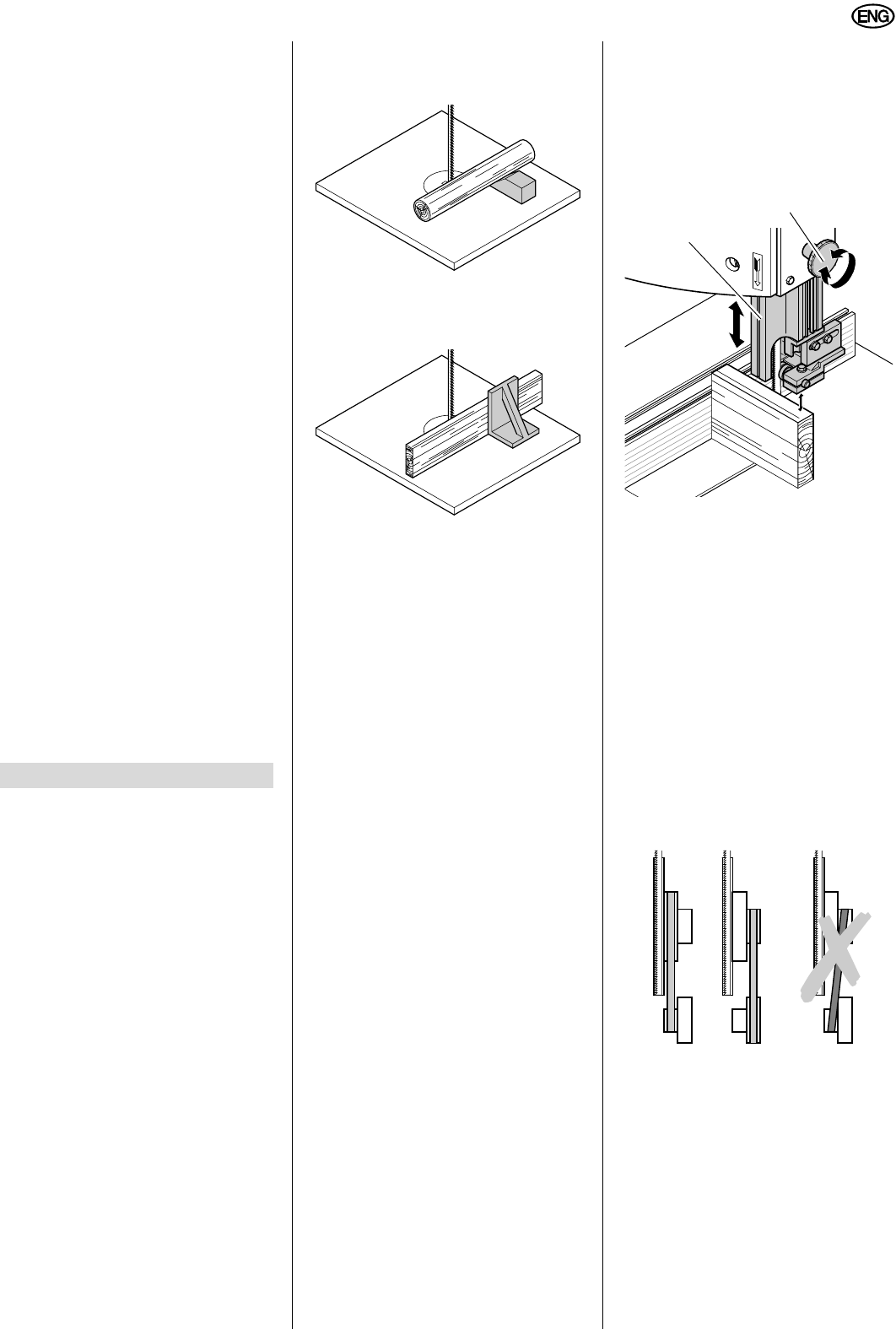

Upper blade guide adjustment

The height of the upper blade guide (48)

needs to be adjusted:

− prior to every cutting operation, to

accommodate the height of the

workpiece (the upper blade guide

should be set approx. 3 mm above

the workpiece);

− after adjustments of band saw blade

or saw table (e.g. band saw blade

change, tensioning of the band saw

blade, saw table alignment).

A

Danger!

Before adjusting the upper

blade guide and saw table tilt:

− switch machine OFF.

− Wait until the band saw blade has

come to a complete stop.

1. Loosen locking screw (49).

2. Slide the upper blade guide (48) into

desired position.

3. Tighten the locking screw (49)

again.

Cutting speed adjustment

1. Open the lower housing door.

2. Slacken V-belt by turning the crank

clockwise.

3. Shift the V-belt to the desired pulley

on the drive wheel (lower band saw

wheel) and to the corresponding

motor pulley.

A

Caution!

The V-belt must run either on

both front or both rear pulleys. Never

have the V-belt run diagonally!

− V-belt on front pulley

= low speed, high torque.

− V-belt on rear pulleys

= high speed, low torque.

4. Tighten the V-belt again by turning

the crank counter-clockwise (half-

way between the pulleys the V-belt

should flex approx. 10 mm).

5. Close the lower housing door.

Information on how to set the cutting

speed can also be found on the label on

the inside of the lower housing door.

8. Operation

3 mm

48

49

800 m/min370 m/min