Section

3

Transmitter Description

3.0 Detailed Description

The LTM-Series is an assembly of two major

components:

The Sensor Tube Assembly: This is a 5/8” diameter

stainless steel probe, sealed on one end, with the

magnetostrictive waveguide in its center. In

addition to the magnetostrictive waveguide, the

tube also houses the optional temperature sensor

and the sensing elements. The tube is made to

lengths of 2-30ft. in rigid construction.

The Enclosure and Electronics: The extruded

aluminum housing has two compartments. The

enclosure is rated NEMA 4X and 7. One side

contains the microprocessor board assembly and

calibration push buttons. The other side contains

the field wiring termination board. The electronics

module is connected to the detector board of the

sensor tube assembly via a plug-in cable. The

electronics module houses printed circuit boards

(PCB) that encompass surface mount component

construction utilizing the latest integrated circuit

technology.

Magtech also has a stainless steel enclosure

that can be utilized. Please contact factory for

further details.

3.1 Technology – Theory of Operation

The LTM-250/350 series level transmitters are

based on the principle of magnetostriction, first

used for digital delay lines and later precision

distance or displacement in the machine tool

industry. This principle, if designed and applied

properly, has potentially very high measurement

resolution, typically better than 0.001 inch. In the

machine tool industry such a high resolution is

desirable. In the level measurement application,

however, a resolution of 0.03 inch is more than

adequate.

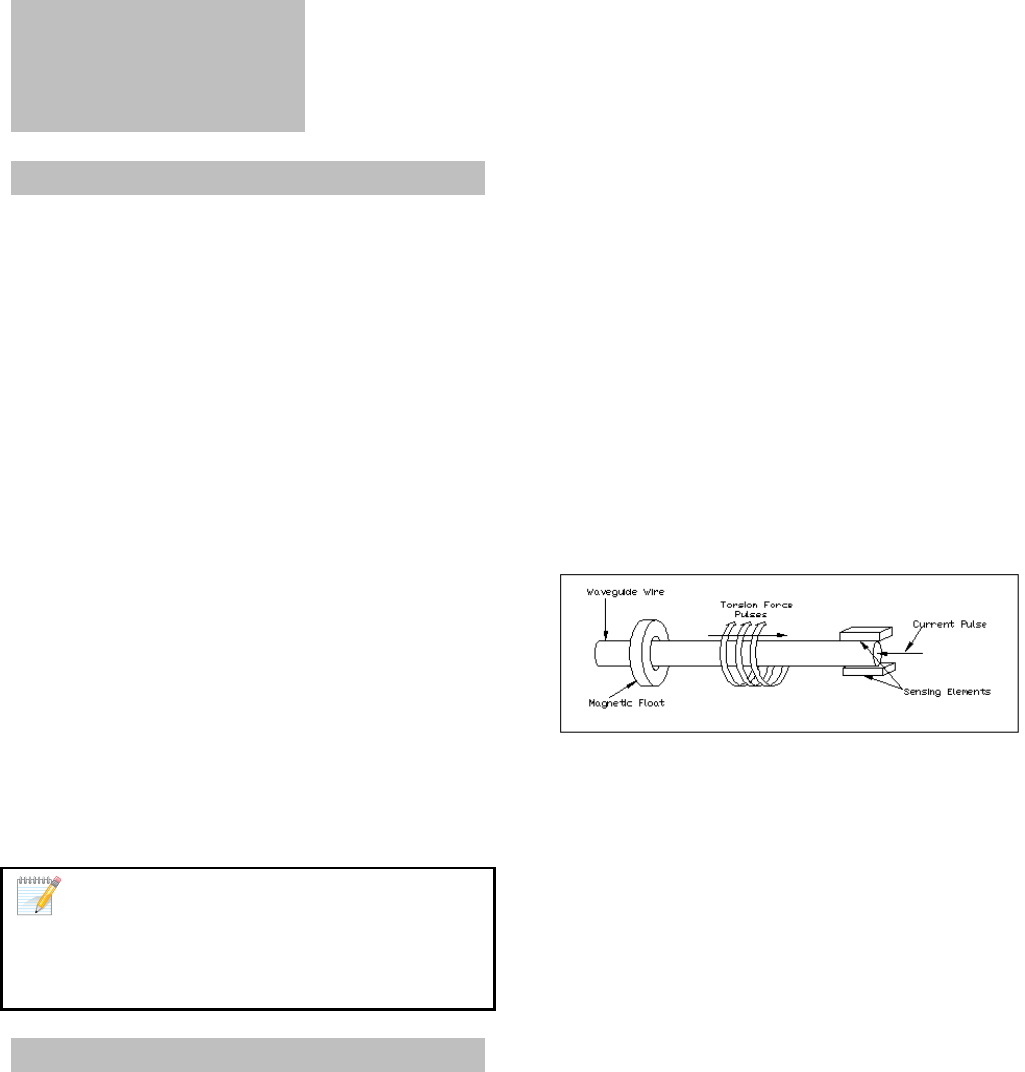

In a brief description, the magnetostrictive principle

consists of a wire extruded and heat treated under

carefully chosen conditions to retain desired

magnetic properties, which is pulsed by a circuit

with a relatively high current pulse. The high

current pulse produces a circular magnetic field as it

travels down the wire at the speed of sound.

Another magnetic field generated by a permanent

magnet (the float), placed near or around the wire

at some distance from the point of entry of this

pulse interferes with the magnetic field of the

current pulse and a torsional force results at the

collision point.

Figure 6. Principle of Operation

The effect of this torsion force is a twist to the wire

at this point producing torsion wave traveling

towards both ends of the wire. The propagation

time (or time-of-flight) of this wave is measured

precisely and if the wire properties remain stable, it

is very repeatable at about 5-10 microseconds per

inch, which is approximately the speed of sound in

that medium. By measuring the exact number of

microseconds it took the torsion wave to reach a

designated termination point of the wire, the

distance to the magnet from this termination point

can be easily calculated.

5