9

3. Now that the blade slot in the blade barrel (10) is empty

you can proceed to either turning over the existing planer

blade or install a new planning blade by following the

instructions.

Installing planer blades

1. The blades are reversible as

they have a cutting edge on

both sides. If a blade is worn

or damaged, the blade can

be removed and put the other

way around. Either turn the

existing planer blade (9) over

or replace it if required.

2. Slide the good blade face up onto the blade support

block of the blade barrel.

Note. If a blade is damaged, it can be replaced without the

need to replace the other two blades. When blades are

worn, they must be replaced as a set of three to prevent

unbalanced operation with consequential dangerous

vibration and possible damage to the tool.

Note. Ensure that the blades are positioned such so that

they are flush with the rebate side of the base to enable

correct rebating.

CAUTION. The blades must

not protrude out from the base

rebate side. This may cause an

injury and break the guard. There

has to be enough clearance so

that the blades do not touch the

drum guard in use.

Note: The ridge along the blade

should be on the blade face on the opposite side of the

clamping screws.

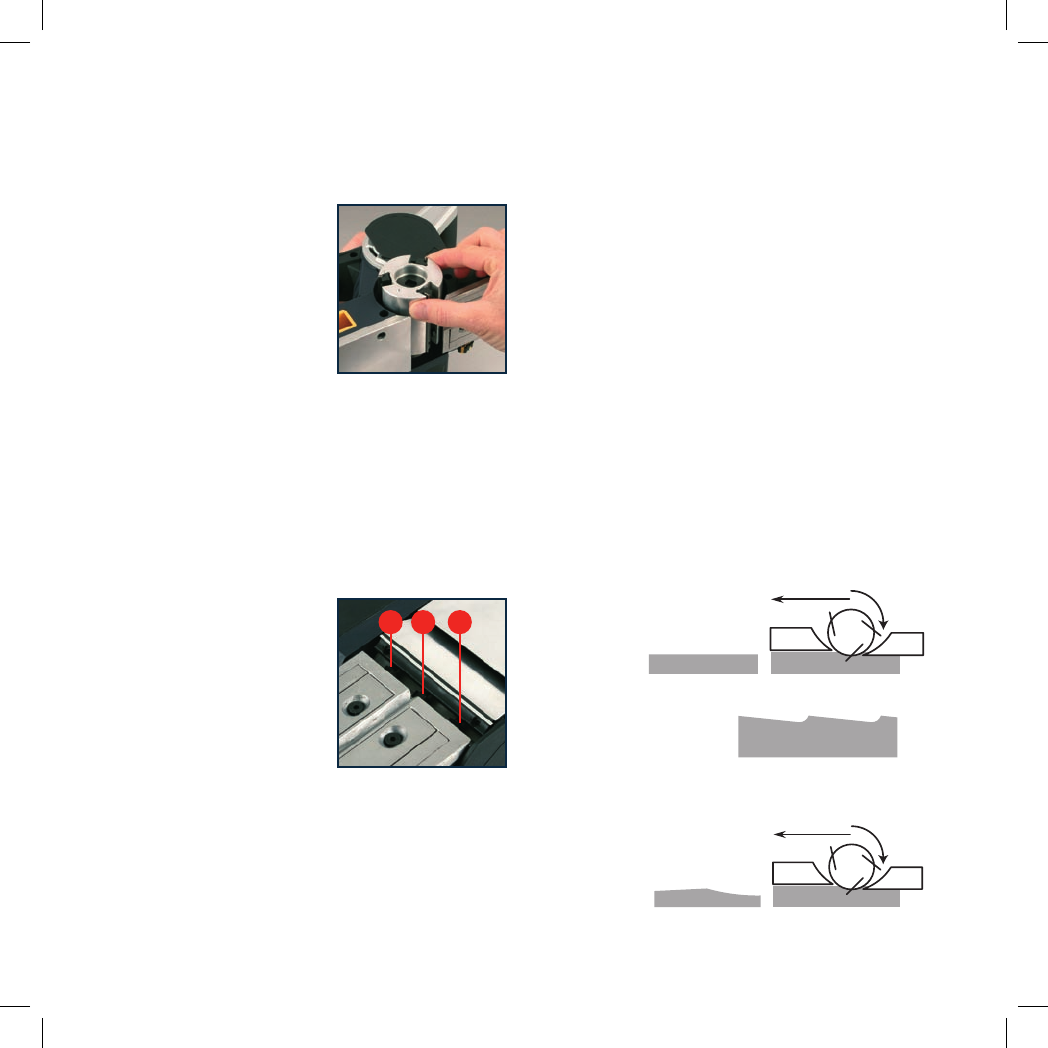

3. Tighten the clamping screws, ensuring that they are

tightened evenly in the following manner.

Tighten the two outside clamping screws snug tight,

then the middle screw.

Working in the same order, fully tighten all three screws.

4. Loosen the vice and rotate the planer barrel and

move onto the next planer blade, repeating the above

blade removal and installation process for the remaining

two blades.

5. Once the new blades have been installed remove

blade barrel from vice and continue onto reinstalling

the planer drum.

CAUTION. When installing blades, first clean out all chips

or foreign matter adhering to the blade barrel (10) and the

blades themselves. Use blades of the same dimensions

and weight, or the barrel will oscillate and vibrate causing

poor planing action and possibly a machine breakdown.

Tighten the clamping screws (11) carefully when attaching

the blades to the planer. A loose clamping screw could

be extremely dangerous. Regularly check to see they are

tightened securely.

It is essential that the blades sit square in the slot and that

they are fully inserted prior to tightening the clamping screws.

If the blades protrude or are not square, they could hit the

casing with serious risk to the operator and others in the vicinity.

Correct setting

• Correct setting

• Clean smooth cut.

• Nicks in surface – as caused by the edge of one or all

blades not being parallel to the rear base line.

1 3

2

(a)

(b)

(a)

(b)

(a)

(b)

(a)

(b)

(a)

(b)

(a)

(b)

(a)

(b)

(a)

(b)

(a)

(b)