Troubleshooting

309977H 9

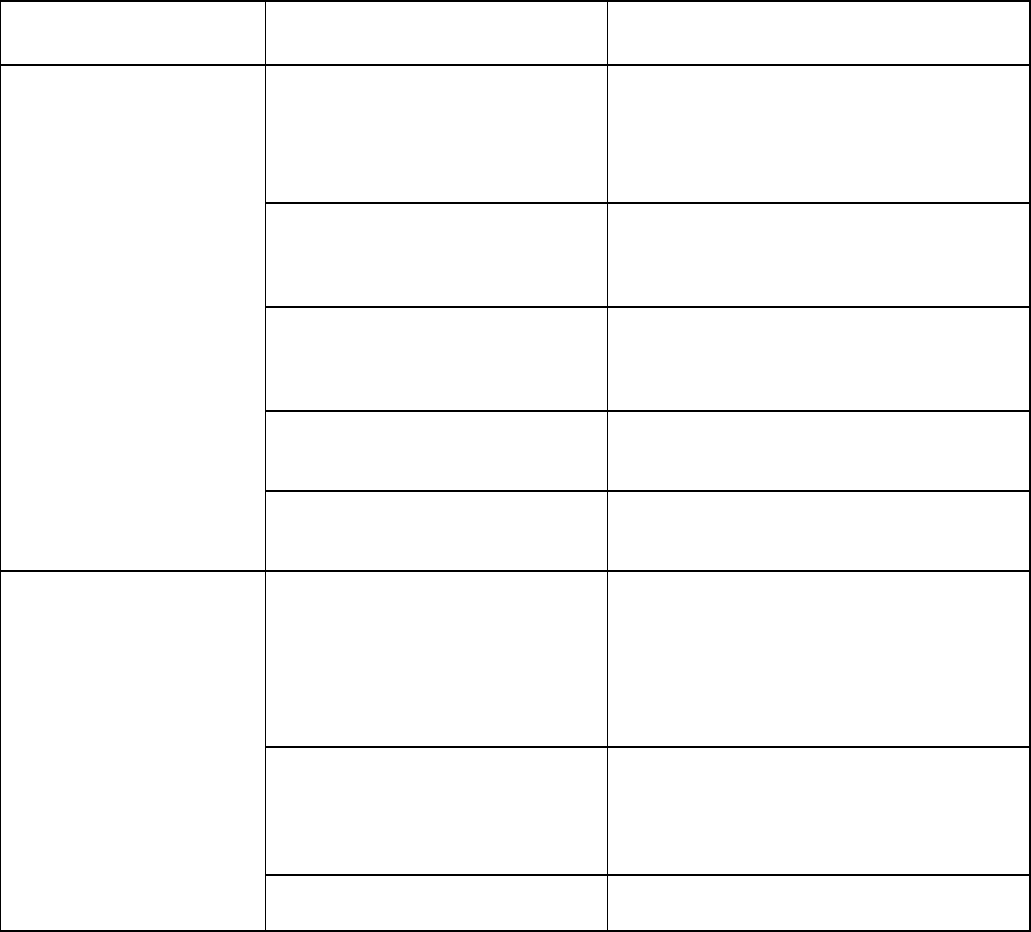

Basic Electrical Problems

(continued)

7. Brush length which must be 1/4

in, minimum. See page 14.

NOTE: Brushes do not wear at

the same rate on both sides of

motor. Check both brushes.

7. Replace brushes. See page 14.

8. For broken or misaligned motor

brush springs. Spring must rest

squarely on top of brush. See

page 14.

8. Replace brush if spring is broken. See

page 15.

9. Motor brushes may be binding in

brush holders. See page 15.

9. Clean brush holders. Remove carbon with

small cleaning brush. Align brush leads

with slot in brush holder to assure free ver-

tical brush movement.

10. Motor armature commutator for

burn spots, gouges and extreme

roughness. See page 14.

10. Remove motor and have motor shop

resurface commutator, if possible. See

page 15.

11. Motor armature for shorts using

armature tester (growler) or per-

form spin test. See page 13.

11. Replace motor. See page 15.

Refer to wiring diagram on

page 29 to identify test

points (TP).

1. Power supply cord. Connect volt

meter between TP1 (L1, 240

Vac) and TP2 (L2, Neutral). Plug

in sprayer. Meter must read:

210-235 Vac for 220-240 Vac

models; 85-130 Vac for 100-120

Vac models. Unplug sprayer.

1. Replace power supply cord.

2. Motor thermal cutoff switch. Turn

sprayer OFF. Check for continuity

between TO1 and TO2 with ohm-

meter.

2. If thermal switch is open (no continuity),

allow motor to cool. If switch remains open

after motor cools, replace motor. If thermal

switch closes after motor cools, correct

cause of overheating.

3. All terminals for damage or loose

fit.

3. Replace damaged terminals and recon-

nect securely.

TYPE OF PROBLEM

WHAT TO CHECK

If check is OK, go to next check

WHAT TO DO

When check is not OK, refer to this column