Drive Housing and Connecting Rod

8 311019L

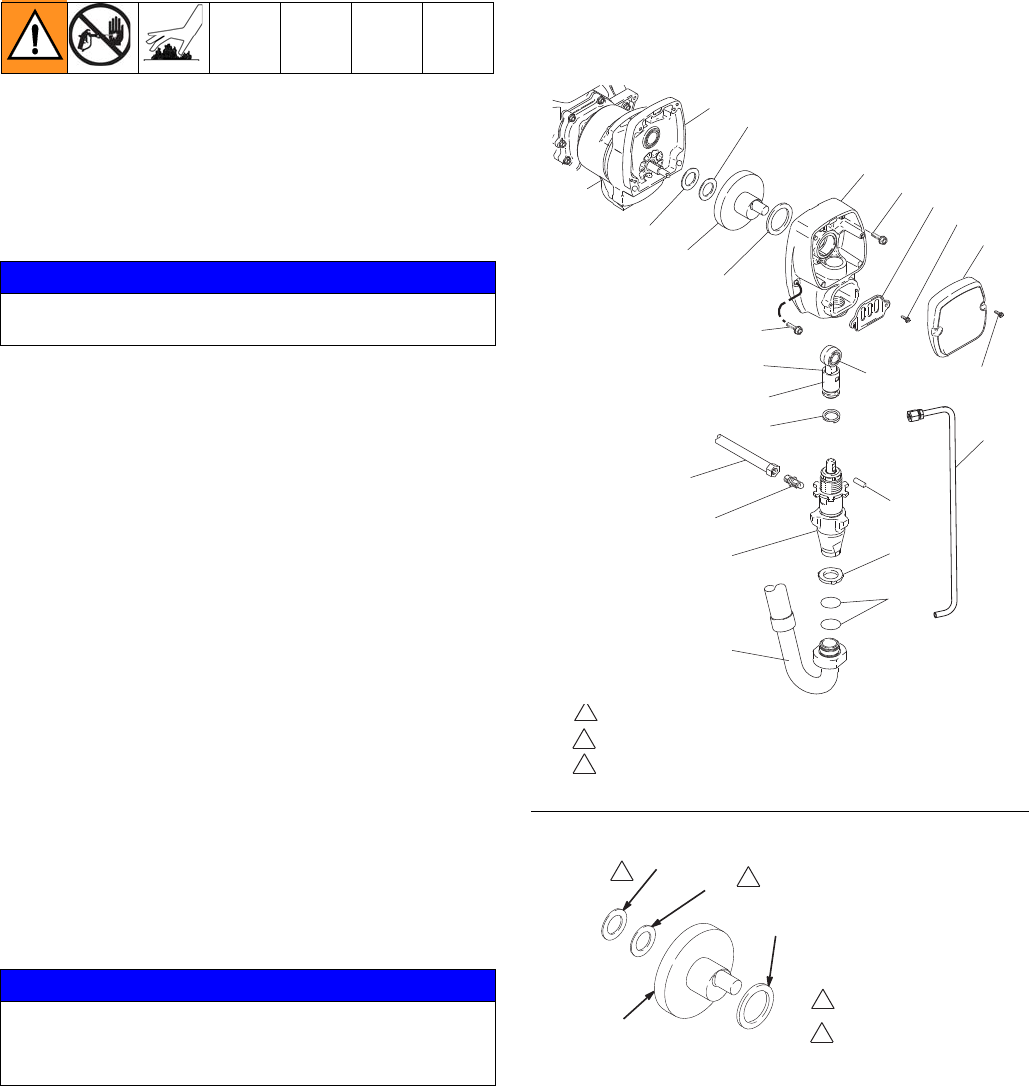

Drive Housing and Connecting Rod

Removal

1. Relieve pressure, page 5.

2. F

IG. 2. Remove screws (32) and front cover (52).

3. Remove pump. Refer to Displacement Pump, Removal,

page 14.

4. Remove four screws (34) from drive housing (43).

5. Pull connecting rod (29) and lightly tap lower rear of drive

housing (43) with plastic mallet to loosen from pinion

housing (44). Pull drive housing and connecting rod

assembly off pinion housing.

6. Inspect crank (47) and connecting rod (29) for excessive

wear and replace parts as needed.

Installation

1. Evenly lubricate inside of bronze bearing (C) in drive

housing (43) with high-quality motor oil. Liberally pack top

roller bearing (E), lower bearing (D) inside connecting rod

(29) with bearing grease.

2. Assemble connecting rod (29) to drive housing (43).

Rotate connecting rod to lowest position.

3. Apply grease to washers 46, 49 and 48. Install in order

shown in F

IG. 3.

4. Lubricate gears with 0.26 pint of 110293 grease (supplied

with drive housing). Pack grease evenly around gears.

5. Clean mating surfaces of pinion and drive housings.

6. Align connecting rod with crank (47) and carefully align

locating pins in drive housing (43) with holes in pinion

housing (44). Push drive housing onto pinion housing or

tap into place with plastic mallet.

7. Install screws (34) in drive housing. Torque evenly to note

3 value in Fig. 1.

8. Install pump. Refer to Displacement Pump, Installation,

page 14

9. Install front cover (52) with two screws (32).

FIG. 3

NOTICE

Thrust washers may stick to grease inside of drive housing.

Do not lose or misplace.

NOTICE

DO NOT use drive housing screws (34) to align or seat

bearing housing with drive housing. Align these parts with

locating pins, to avoid premature bearing wear.

FIG. 2

1

2

3

ti24871a

140

32

52

32

44

49

47

48

29

28

136

141

118

31

33

57

27

46

43

34

107

34

E

D

Oil

Pack with bearing grease 110293

Torque to 130 - 150 in-lb (14 - 16.9 N.m)

ti5990a

1

2

Steel

1

2

46

49

48

47

Copper