Setup

10 3A1456D

Materials

NOTE: When spraying water-based materials, flush the

sprayer thoroughly with water.

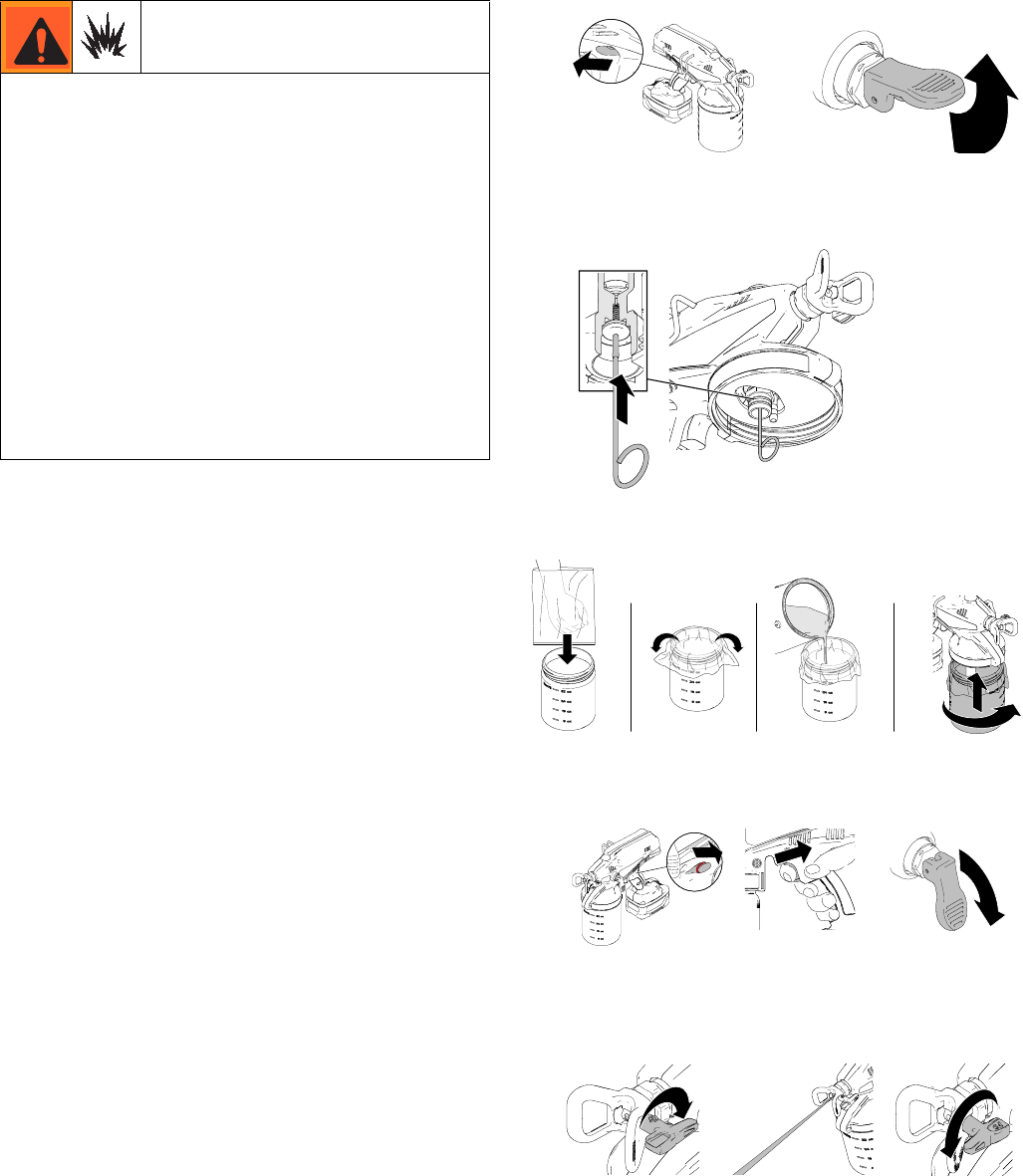

Starting a New Job (or Refilling the Cup)

1. Engage trigger lock and put prime/relief valve UP to

release pressure.

2. Use the Fine-Finish Optimizer cleaning tool to lightly

push on inlet valve to make sure it moves up and

down freely.

3. Install material cup liner, fill with material, and

thread onto sprayer.

4. To prime pump, disengage trigger lock and trigger

sprayer for 10 seconds. Then release trigger and

put prime/relief valve DOWN to spray position.

5. Reverse spray tip to UNCLOG position and spray

into waste area for five seconds. Then rotate tip

back to SPRAY position. NOTE: Failure to perform

this operation could result in poor spray pattern.

NOTE: If sprayer fails to prime, follow Alternative

Priming Method (page 19) and/or Inlet Valve

Cleaning (page 20).

Use only water-based materials. Do not use materi-

als which state “FLAMMABLE” on the packaging. For

more information about your material, request MSDS

from distributor or retailer.

Spraying certain materials may cause static

build-up in the sprayer that can result in static

shock to the user. If this occurs, first ensure the mate-

rial has a flash point greater than 100° F (38° C) and

does not state that it is FLAMMABLE anywhere on the

package. If still feeling a static shock, the material likely

contains a non-mineral spirits fluid such as, but not lim-

ited to, xylene, toluene, or naphtha, which can build up

static. Switch to an alternative material.

Keep spray area well-ventilated. Keep a good supply

of fresh air moving through the area.

ti14999a

ti14994a

ti15474a

ti15418a

ti15425a

ti14995a