Repair

14 311322K

5. Remove check valve and clean with gun

cleaner. Inspect and replace if damaged.

6. Remove side seal and o-ring. Replace if

damaged.

7. Clean all components thoroughly. Use

brass brushes or drill bits to remove resid-

ual chemical from the gun block. Thorough

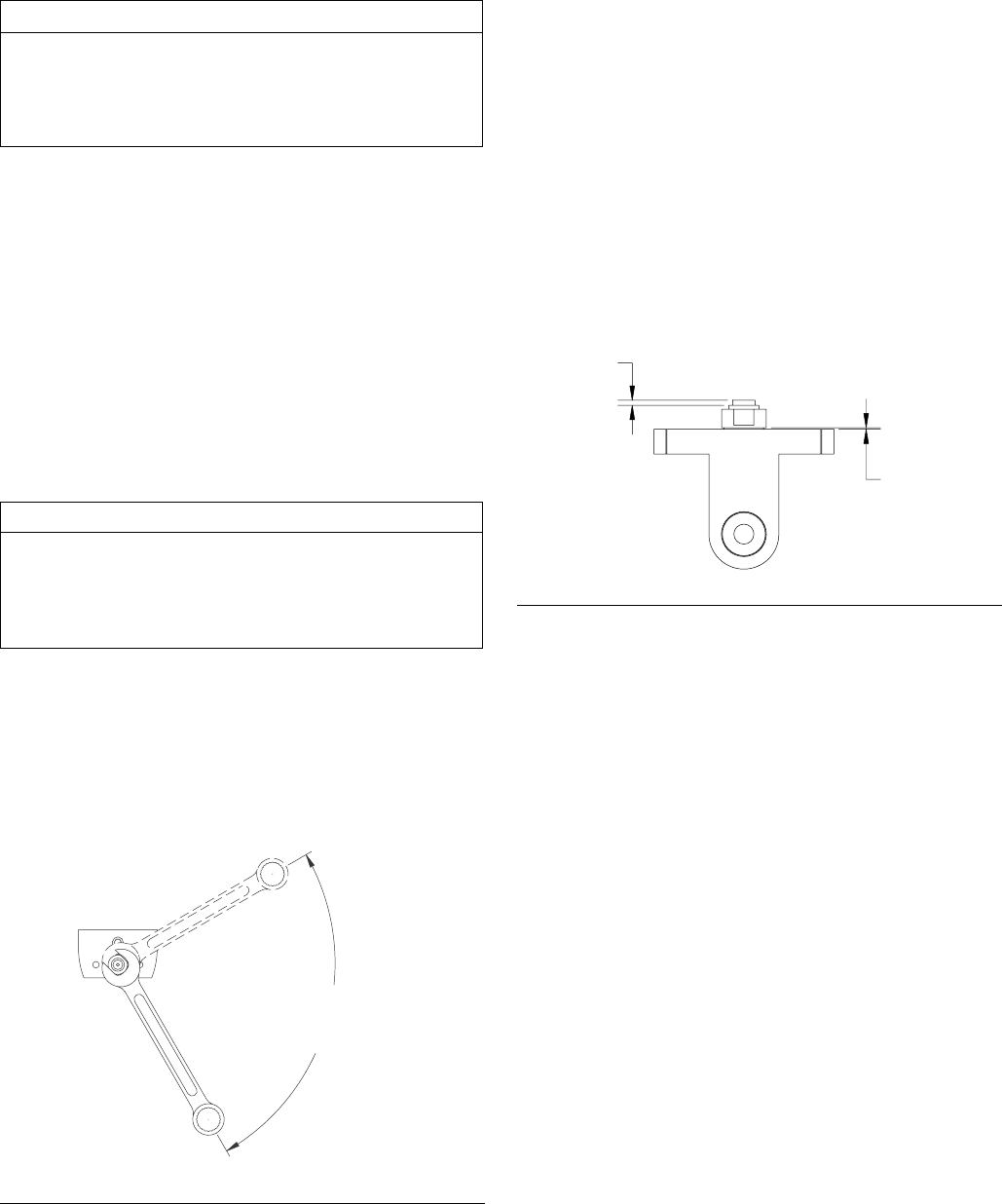

cleaning ensures unrestricted movement of

mixing chamber. Use cotton swabs soaked

in gun cleaner if necessary.

8. Repeat steps 4-7 for R-side block.

9. Place check valve assembly in check valve

retainer and thread into side block finger

tight. Use a 1/2 in. wrench to tighten

retainer 1/4 turn and no more. See FIG. 8.

10.Check side seal for wear by measuring how

far seal protrudes from side seal assembly

insert. A worn side seal promotes chemical

leakage. Replace side seal if it protrudes

0.065 in. (1.65 mm) or less. In addition,

check seal for scratches, which also pro-

mote leakage. See FIG. 9.

11.Inspect check valve assembly for damage

by measuring gap between mating surface

of side block and bottom edge of side seal

assembly insert. If gap measures 0.018 in.

(.46 mm) or less, the check valve assembly

has been crushed due to overtightening

and it must be replaced. See FIG. 9.

12.Place spring in check valve retainer.

13.Lightly coat o-ring with grease and install

on side seal.

14.Push side seal into the check valve retainer

until o-ring engages detent groove and

remains in place.

15.Install side blocks to gun body with two

mounting screws. Tighten screws alter-

nately and evenly to prevent leakage.

16.Return gun to service. See Daily Start-Up,

page 11.

CAUTION

Clean side seals with a wooden or plastic

scraper or a brass brush. Do not use a pock-

etknife, razor blade, or any tool that may

scratch surface.

CAUTION

Do not overtighten check valve retainer.

Tightening more than 1/4 turn can damage

check valve or retainer and cause leaking

when gun is pressurized.

FIG. 8. Tighten Check Valve Retainer

One quarter of a

full turn (max.)

FIG. 9: Side Seal

.018 in.

(0.46 mm)

.065 in.

(1.65 mm)