Repair

311322K 21

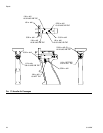

Trigger/Air Valve

1. Follow Pressure Relief Procedure, page

12.

2. Use a 5/16 in. nut driver to alternately

loosen side block mounting screws. Care-

fully separate side blocks from gun. Wipe

mating surfaces with a rag soaked in gun

cleaner.

3. If gun is configured with air inlet at base of

handle (standard), remove 1/8 npt pipe

plug at rear of gun.

If gun is configured with air inlet at rear,

remove air hose and nipple.

4. Remove screw and locknut holding trigger

lever in place. Remove trigger lever.

5. Remove valve retainer hex nut, which holds

brass valve spool in place.

6. Carefully grip end of valve spool with a pli-

ers and remove it. Valve spring, which fits

into spool, will come out with it. Be careful

not to lose spring.

7. Inspect spool o-rings and replace if dam-

aged. Liberally coat new o-rings with Lubri-

plate grease before installing.

8. Remove 1/16 npt pipe plug from deep in

port at rear of gun.

9. Brass spring seat is visible inside port at

rear of gun. Use a 1/4 in. diameter (maxi-

mum) punch and hammer to gently tap

seat until valve liner and seat are pushed

out of valve cavity.

10.Inspect the four o-rings on valve liner and

replace if necessary. Apply Lubriplate

grease liberally to o-rings before installing.

11.Ensure that valve cavity is free of debris.

Apply a thin film of Lubriplate grease inside

cavity.

12.Slide spring seat into cavity, tapered end

first. Ensure it bottoms out in cavity.

13.There will be some resistance from the

o-rings when installing valve liner. Push

valve liner into cavity until 2 or 3 of the cav-

ity’s internal threads are visible.

14.Apply a small amount of thread sealant to

1/16 npt pipe plug and reinstall. This seals

threads to prevent air leaks.

15.Reinstall 1/8 npt pipe plug, or nipple and air

hose, at rear of gun.

16.Ensure that valve spring is in place, and

insert valve spool into valve liner. Screw in

valve retainer nut until snug. Do not over-

tighten.

17.Reinstall trigger lever, screw, and locknut.

18.Install side blocks to gun body with two

mounting screws. Tighten screws alter-

nately and evenly to prevent leakage.

19.Return gun to service. See Daily Start-Up,

page 11.

To repair side blocks, see Side Blocks,

page 13.

Threads allow engagement with valve

retainer nut, which aligns valve liner and

spool to proper depth.