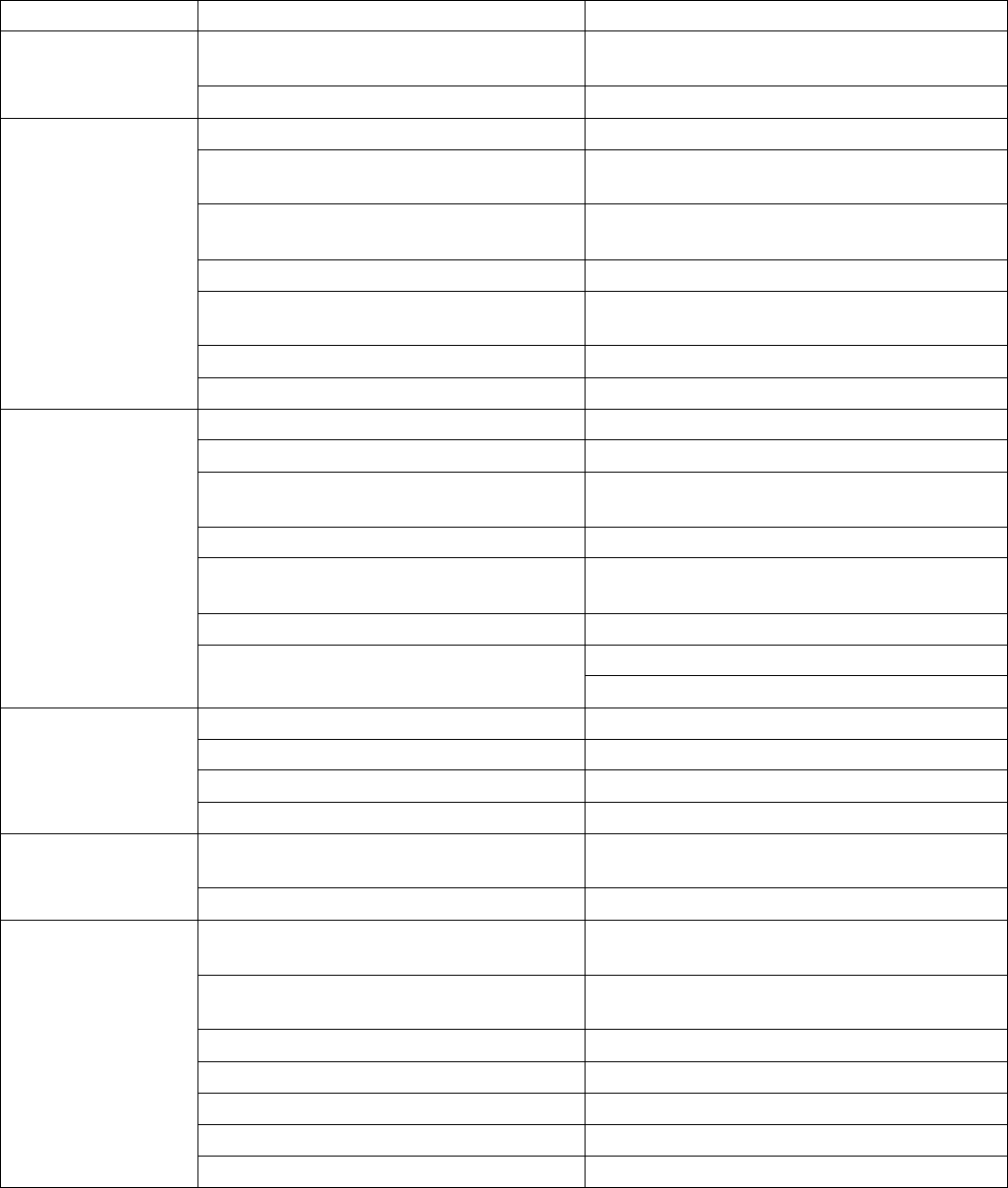

Troubleshooting

14 332574D

Troubleshooting

Problem Cause Solution

Premature anvil or

blade wear

Excessive tension between anvil and cutter

head

Adjust Anvil to Cutter Head Tension, page 8

Cutter speed faster than necessary Premature Blade or Anvil Wear, page 7

Roving binds up in

Cutter

Obstruction in roving path Ensure the roving path is free from obstruction

Overspray/binder build up on internal com-

ponents

Clean components and reinstall the cover

Resin on roving Clean as necessary, keep roving away from

resin and overspray.

Incorrect anvil to idler wheel tension Adjust Anvil to Idler Tension, page 9

Incorrect anvil to cutter blade assembly ten-

sion

Adjust Anvil to Cutter Head Tension, page 8

Cutter blade assembly is worn out Replace

Anvil is worn out Replace

Cutter does not actu-

ate when the gun is

triggered

Air supply to gun is shut off Open air supply

Speed control in off position Adjust Cutter Speed, page 8

Quick release plunger stuck in Inspect, clean and lubricate, replace if neces-

sary

Incorrect anvil to idler wheel tension Adjust Anvil to Idler Tension, page 9

Incorrect anvil to cutter blade assembly ten-

sion

Adjust Anvil to Cutter Head Tension, page 8

Cutter air valve stuck Inspect and replace if necessary

Air motor is “locked up” Add oil to air motor, page 10

Check for free rotation, replace if necessary

Cutter is cutting long

strands

Anvil to cutter blade tension is incorrect Adjust Anvil to Cutter Head Tension, page 8

Anvil to blade tension lockdown is loose Tighten the anvil to blade tension lockdown

Anvil is worn out Replace Anvil, page 11

Cutter blade assembly is worn out Replace Blades, page 12

Air motor spins but

doesn't cut glass

Cutter head set screws (606) loose. Apply medium strength thread sealant and

tighten

Anvil to cutter blade tension is incorrect Adjust Anvil to Cutter Head Tension, page 8

Air motor speed

incorrect

Incoming air supply issues Ensure proper air supply to gun, see Technical

Data, page 27

Supply air volume too low Ensure adequate air volume, see Technical

Data, page 27

Air motor speed control set incorrectly Adjust Cutter Speed, page 8

Anvil to cutter blade tension is too high Adjust Anvil to Cutter Head Tension, page 8

Air blowing out oil hole Air motor installed incorrectly, page 17

Cutter blade assembly is worn out Replace Blades, page 12

Air motor exhaust filter plugged Clean and replace as necessary, page ###