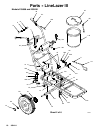

309414 13

Pressure Control

Control Board

Removal

1.

Relieve press ure; page 4.

2. Fig. 6. Remove four screws (93) and

display/cover (139). Pull display connector wings

open on PC board and pull display connector out.

3. Fig. 14. Disconnect at control board (109):

D Lead (D) from potentiometer.

D Lead (E) from trans ducer.

D Remove ON/OFF switch (24) connecto r (A).

4. Fig. 6. Remo ve six screws (214) from control board

(109) and green ground wire.

5. Remove two connectors (Y) at backside of pres-

sure control. Remove jam nuts (Z) and contro l

board (109).

Installation

When installing replacement control board, fo llow

instru ctions with control board to set model type.

1. Fig. 6. In stall control board (109) and jam nuts (Z).

Install two connectors (Y) at backside of pressure

contro l.

2. Install green ground wire and contr ol board (109)

with six screws (214).

3. Fig. 14. Connect to contr ol board (109):

D Connect ON/OFF switch (24) connector (A).

D Lead (E) to transducer.

D Lead (D) to potentiometer .

4. Fig. 6. Push display connector into PC board clos e

display connec tor wings on PC board. Install

display/cover (139) with four screws (93).

Pressure Control Transducer

Removal

1.

Relieve press ure; page 4.

2. Fig. 6. Remove four screws (93) and

display/cover (139).

3. Disconnect lead (E) from contr ol board (109).

4. Remove tw o screws (201) that connect control

housing (108) to filter housing (200e). Fro m inside

of control box, pull transducer connecto r through

contr ol housing (108).

5. Remove pres sure control transducer (200p) and

o-ring (200r ) from filter housing (200e).

Installation

1. Fig. 6. Install o-ring (200r ) and pressure control

trans ducer (200p) in filter housing (200e). Torque

to 30 --36 ft-lb.

2. Install transducer cable thr ough control box. Ins tall

filter housing and spacer to control box with two

screws (201).

3. Connect lead (E) to motor control board (109).

4. Install display/cover (139) with four sc rews (93).

Pressure Adjust Potentiometer

Removal

1.

Relieve press ure; page 4.

2. Fig. 6. Remove four screws (93) and

display/cover (139).

3. Disconnect lead (D) from contr ol board (109).

4. Loosen set screws on potentiomete r knob (19) and

remove knob, shaft nut, lockwasher and pressure

adjust potentiometer (81).

5. Remove seal (148) from potentiometer (81).

Installation

1. Install seal (148) on potentiometer (81).

2. Fig. 6. In stall pressu re adjust potentiometer (81),

shaft nut, lockwasher and potentiomete r knob (19).

a. T urn potentiomete r shaft (81) clock wise to

internal stop. Assemble potentiometer knob

(19) to strike pin on plate (23) .

b. After adjustment of step a., tighten both set

screws in knob 1/4 to 3/8 turn after contact

with shaft.

3. Connect lead (D) to control board (109).

4. Install display/cover (139) with four sc rews (93).