Troubleshooting

22 313516G

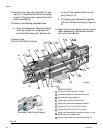

Spray Pattern Troubleshooting

Fluid needle will not trigger. Loose or missing fluid needle stop

(29) or setscrew (30).

Air leaking around piston (3).

Swollen piston o-ring (8).

Insufficient air pressure on trigger.

Plug (19) is in incorrect fluid port.

Replace stop or tighten setscrew.

Replace o-ring (8) or piston.

Replace o-ring. Do not immerse

piston in solvent.

Increase air pressure or clean air

line.

Move plug to fluid port consistent

with manifold plumbing, unless

you are using gun in a circulating

system. If you are, all fluid ports in

gun and on manifold should be

open.

Fluid does not shut off. Worn o-ring (11) or (9).

Piston cap (4) not fully tightened.

Spring (6) not in place.

Swollen piston o-ring (8).

Replace o-ring.

Tighten piston cap until it bottoms

out.

Check spring position.

Replace o-ring. Do not immerse

piston in solvent.

Problem Cause Solution

Problem Cause Solution

Fluid flow is fluttering while spray-

ing.

Fluid nozzle is not tight enough.

O-ring (36) is missing or dam-

aged.

Fluid filter is clogged.

Tighten fluid nozzle to 60 in-lb

(6.8 N•m).

Replace o-ring.

Check fluid filter.

Fluid flow fades while spraying

high viscosity fluids.

Fluid pressure is too low, causing

fluid flow to reduce when gun is

elevated.

Raise fluid pressure at source or

use a smaller fluid nozzle.

Pattern becomes off-set or heavy

on ends.

Air cap horn holes plugged or

damaged.

Clean air cap horn holes with

non-metallic item such as a tooth-

pick, or replace air cap.

Gun fluid pressure is too high with

gun triggered.

Using needle/nozzle kit with too

small orifice.

Use needle/nozzle kit with larger

orifice.

Fluid system will not operate at

low enough fluid pressure [below

10 psi (70 kPa, 0.7 bar)].

There is no fluid regulator, or air

regulator on pressure pot is not

sensitive enough at low pressures.

Add low pressure fluid regulator,

or add more sensitive low pres-

sure air regulator on pressure pot.