Service

313516G 25

Reassembly

1. Non-circulating guns only: Lubricate the

backup ring (20†) and o-ring (21†) and

install them on the fluid outlet port plug

(19). Install the plug in the fluid outlet port

of the fluid housing (2). See FIG. 21.

2. All guns: Reinstall the gasket (22) in the

fluid housing (2).

3. Install the o-rings (8*, 9*) on the piston (3).

Install the two o-rings (10*, 11*) on each of

the piston stems (T). Lubricate all the

o-rings, the piston, and the piston stems.

4. Remove the protective paper from the

sticky side of the gasket (12*) and adhere

the gasket to the bottom of the piston hous-

ing (1), making sure the three holes in the

gasket are properly aligned with the match-

ing holes in the housing.

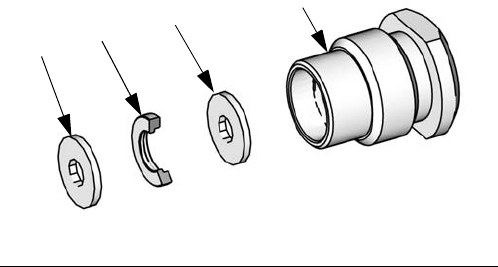

5. Lubricate the washers (45†) and spacer

(46†). Insert them into the packing nut (16)

as shown in FIG. 20, The step on the

spacer faces into the packing nut.

6. Insert the packing nut into the fluid housing

(2) and torque to 95-105 in-lb (10.7-11.8

N•m).

7. Align the gasket (15*) as shown in the

exploded view in FIG. 21. Place the gasket

on the piston housing (1), then install the

fluid housing (2) onto the piston housing.

Torque the two screws (14) to 35-45 in-lb

(4.0-5.1 N•m).

a. Insert the piston (3) into the piston

housing (1).

b. Ensure nozzle sealing o-ring (36) is

installed on nozzle (23).

8. To avoid galling of the fluid nozzle seat in

the fluid housing, apply a thin film of lubri-

cant to the threads. Install the nozzle into

the fluid housing. Torque the nozzle

securely to 35-45 in-lb (4.0-5.1 N•m).

NOTE: If you are replacing the needle tip (5a),

apply semi-permanent anaerobic sealant to

two threads at the end of the needle shaft.

Assemble the needle tip to the shaft and hand

tighten. Allow adequate time for the sealant to

cure before installing the needle assembly into

the gun.

9. Lubricate and install the needle (5) into the

back of the gun assembly. Push it straight

in through the piston.

10.Install the needle stop (29) on the needle.

Coat the setscrew (30) with semi-perma-

nent anaerobic sealant and install the

screw into the needle stop. Torque to

6.5-7.5 in-lb (0.73-0.85 N•m). Pull on the

needle to make sure it seats fully.

11.Install the springs (6, 7).

12.Lubricate the threads of the piston housing

(1). Screw the cap (4) onto the housing

until it bottoms out.

13.Install the air cap (24) and air cap retainer

(25).

14.Reinstall the gun on the manifold using the

four screws (13). Start the threads of all

four screws. Tighten the front two screws

first, and then tighten the back two. Torque

all four screws evenly to 65 in-lb (7.3 N•m).

FIG. 20. Fluid packings

45

46

45

16

ti17603a