Service

24 313516G

13.Remove all o-rings from the piston (3) and

stems (T). Check that the stems are solidly

in place. If they are loose, replace the entire

piston assembly (3).

14.Perform the following applicable step:

a. Non-circulating guns: Remove the fluid

outlet port plug (19), and gasket (22)

from the fluid housing (2). Remove the

o-ring (21) and backup (20) from the

plug. See FIG. 21.

b. Circulating guns: Remove the gasket

(22) from the fluid housing (2). See FIG.

21.

15.Clean all parts and replace any worn parts.

When assembling, lubricate the threads

with anti-seize lubricant.

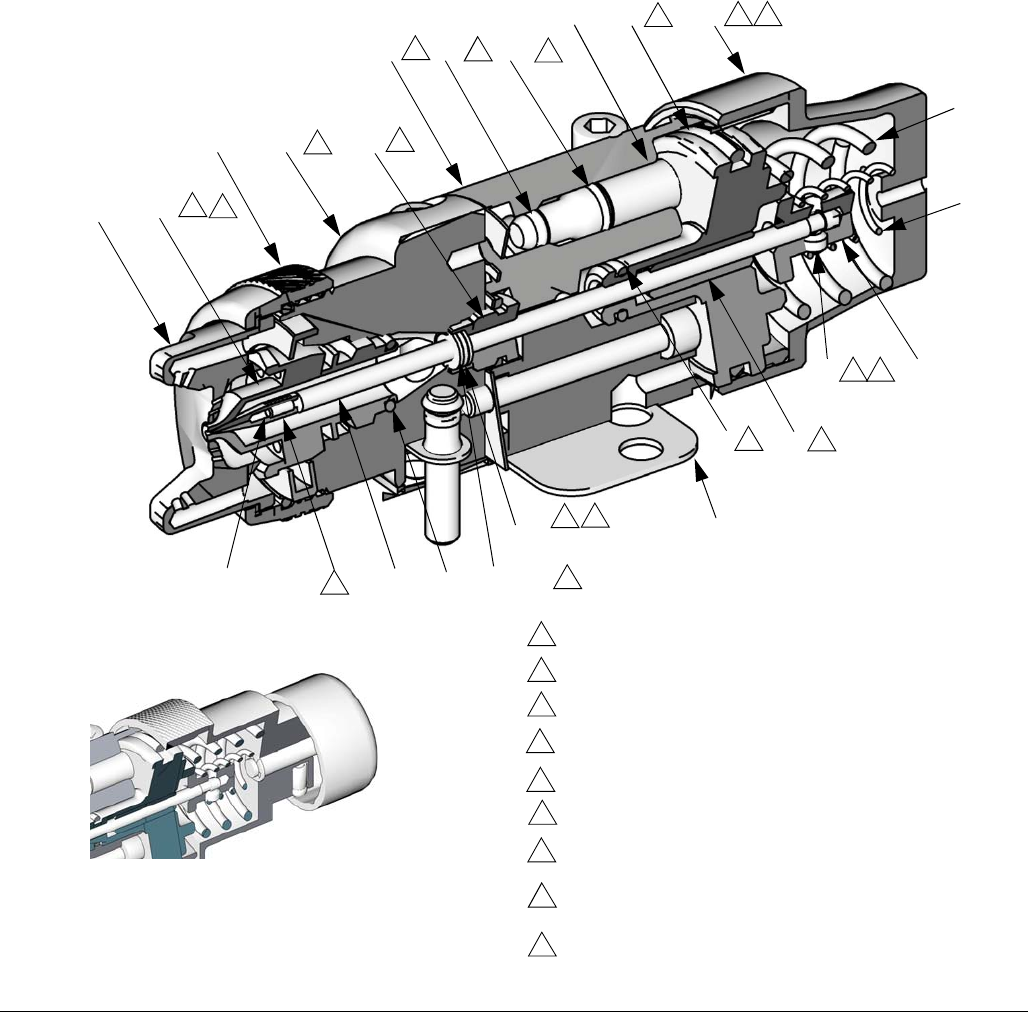

FIG. 19

SERVICE NOTES:

Torque to 35-45 in-lb (4.0-5.1 N•m).

Lubricate threads with anti-seize lubricant.

Lubricate with light-weight oil.

Tighten cap (4) until it bottoms out.

Apply semi-permanent anaerobic sealant.

Torque to 6.5-7.5 in-lb (0.73-0.85 N•m).

Torque to 95-105 in-lb (10.7-11.8 N•m).

Apply semi-permanent anaerobic sealant to two

threads at end of needle shaft.

Step in spacer (46) must face into packing nut.

1

4

3

2

8

7

6

9

Cutaway View:

Part No. 24A749 Gun Shown

4

6

7

29

30

1

8*

T

11*

10*

3

12*

9

16

5

5a

24

23

25 2

1

2

2

3

3

3

3

3

3

4

6 7

8

9

36

ti8199a

Alternate Fluid Control Shown

ti13592b

2

2

45 (x 2)

46

3

10

10