306706 9

Operation/Maintenance

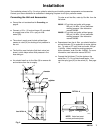

3. Push in on the air valve knob to lower the elevator,

so the cover (A) rests on the top lip of the drum.

The support clamp (K) recesses must be tight

against the elevator riser tube. The pump intake

valve feet (B) must contact and support the perfo-

rated plate (9) as shown in Fig. 2.

4. Raise the elevator 1/4” (6.4 mm), then tighten the

support clamp screws. This ensures that the

cover rests on the drum lip when the elevator is in

the lowered position.

5. Adjust the restrictor valve screw to control the

speed of raising and lowering the unit. Turn the

restrictor screw clockwise to decrease the air

pressure and counterclockwise to increase air

pressure to the elevator. Lock the screw’s position

with the locknut when the adjustment is completed.

6. Unscrew the filter bowl and remove the filter

screen. Replace the bowl. Flush the unit until

clear solvent comes from the gun, then reinstall

the filter screen.

7. Before operation, ensure that all fasteners and

tube connections are tightened securely.

Starting and Adjusting the Pump

1. Lower the pump into the fluid supply drum.

2. Close the air regulator (F).

3. Open the pump’s bleed-type master air valve (E).

4. Hold a metal part of the gun (S) firmly to the side

of a grounded metal pail and hold the trigger open.

5. Slowly open the regulator until the pump starts.

6. Cycle the pump slowly until all air is pushed out

and the pump and hoses are fully primed.

7. Release the gun trigger and lock the trigger safety.

The pump should stall against pressure.

8. If the pump fails to prime properly, open the drain

valve (M). Use the drain valve as a priming valve

until the fluid flows from the valve. Close the

valve.

NOTE: When changing fluid containers with the hose

and gun already primed, open the drain valve (M) to

help prime the pump and vent air before it enters the

hose. Close the drain valve when all air is eliminated.

CAUTION

Do not allow the pump to run dry. It will quickly

accelerate to a high speed, causing damage. If

your pump is running too fast, stop it immediately

and check the fluid supply. If the container is

empty and air has been pumped into the lines, refill

the container and prime the pump and the lines, or

flush and leave it filled with a compatible solvent.

Eliminate all air from the fluid system.

9. With the pump and lines primed, and with ade-

quate air pressure and volume supplied, the pump

will start and stop as you open and close the gun.

In a circulating system, the pump will speed up or

slow down on demand, until the air supply is shut

off.

COMPONENT RUPTURE HAZARD

To reduce the risk of overpressurizing

your system, which could cause compo-

nent rupture and serious injury, never

exceed the specified Maximum Incoming Air Pres-

sure to the pump. (see Technical Data on

page 13.)

WARNING

10. Use the air regulator (F) to control pump speed

and fluid pressure. Always use the lowest air

pressure necessary to get the desired results.

Higher pressures cause premature tip and pump

wear.

Shutdown and Care of the Pump

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 8.

For overnight shutdown, stop the pump at the bottom

of its stroke to prevent fluid from drying on the ex-

posed displacement rod and damaging the throat

packings. Relieve the pressure.

Always flush the pump before the fluid dries on the

displacement rod. See Flushing on page 8.