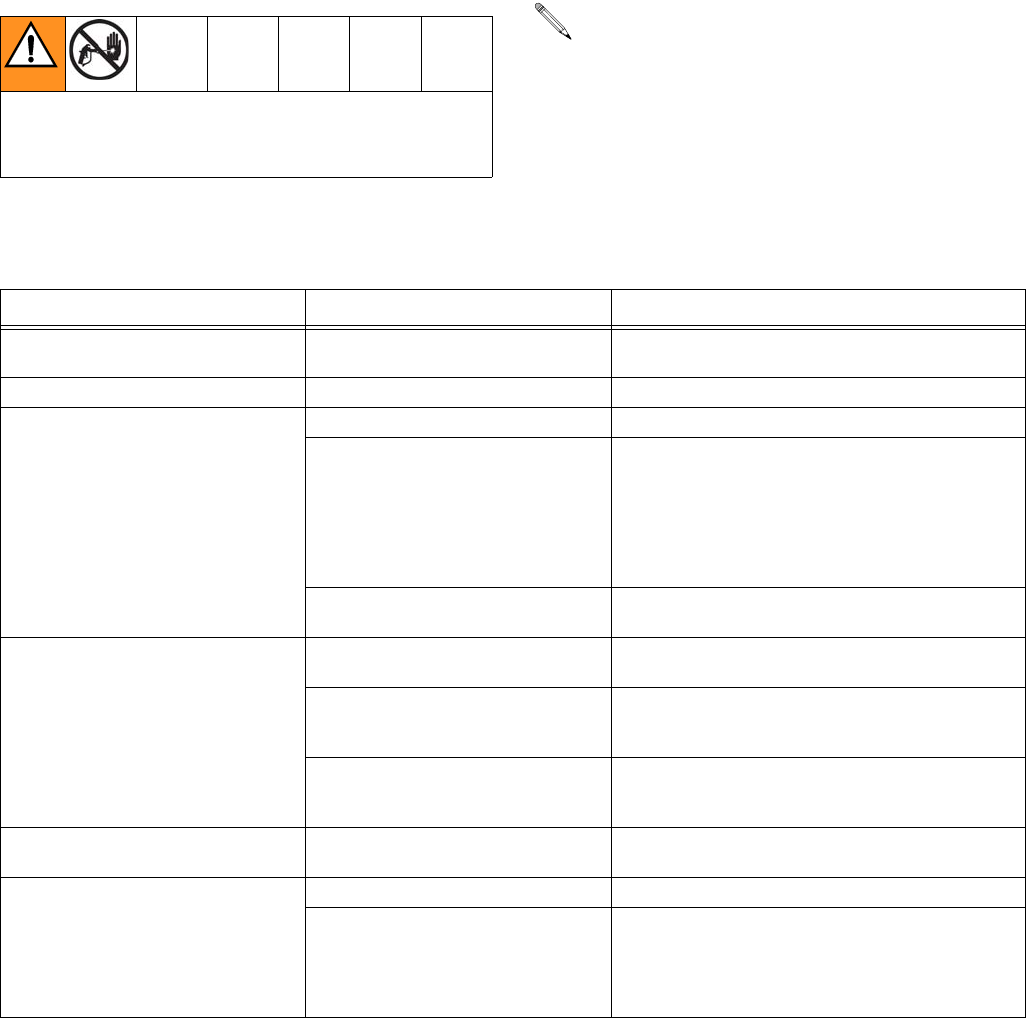

Troubleshooting

18 311001G

Troubleshooting

General Troubleshooting

SKIN INJECTION HAZARD

Follow Pressure Relief Procedure on page 10.

Read warnings, page 4.

• Check all possible remedies in the trouble-

shooting charts before disassembling the gun.

• Some improper patterns are caused by the

improper balance between air and fluid.

Problem Cause Solution

Fluid leakage from back of fluid

packing area.

Worn packings or needle shaft. Replace needle assembly (2).

Air leakage from gun. Air valve not seating properly. Clean or replace air valve (8).

Fluid leakage from front of gun. Needle ball worn or damaged. Replace needle assembly (2) and seat (5c).

Worn seat assembly. Replace the seat (5c) and gasket (5b, carbide

models only). The gasket must be replaced

whenever the seat assembly is removed.

Do not reverse the direction of the plastic seat

(5c, model 288844 gun only) if it is worn. The

seat must be replaced it if is worn.

Fluid viscosity too low for proper

seal with carbide seat.

Install plastic seat (5c).

Fluid in air passages. Spray tip seal leaking. Tighten retaining ring (6) or replace spray tip

(33).

Leaking around seat housing. Replace the gasket (5b, carbide models only).

The gasket must be replaced whenever the

seat assembly is removed.

Fluid inlet fitting leaking. Replace the fluid tube gasket (22). The gas-

ket must be replaced whenever the fluid tube

connector is removed.

Slow fluid shut-off. Fluid buildup on fluid needle

components.

Remove and clean or replace the fluid needle

assembly (2).

No fluid output when triggered. Spray tip plugged. Clean spray tip. See page 14.

Fluid filter or fluid hose plugged. After tip removal (see above), very slowly

loosen the hose end coupling at the gun and

relieve pressure gradually. Then loosen com-

pletely to clear the obstruction. Clean or

replace filter (12).