-28-

G0458 18" Open End Belt/Drum Sander

This section is provided for your convenience—it is not a substitute for the Grizzly Service Department. If

you need help troubleshooting, you need replacement parts, or you are unsure of how to perform the pro

-

cedures in this section, then feel free to call our Technical Support at (570) 546-9663.

SECTION 7: SERVICE

Troubleshooting

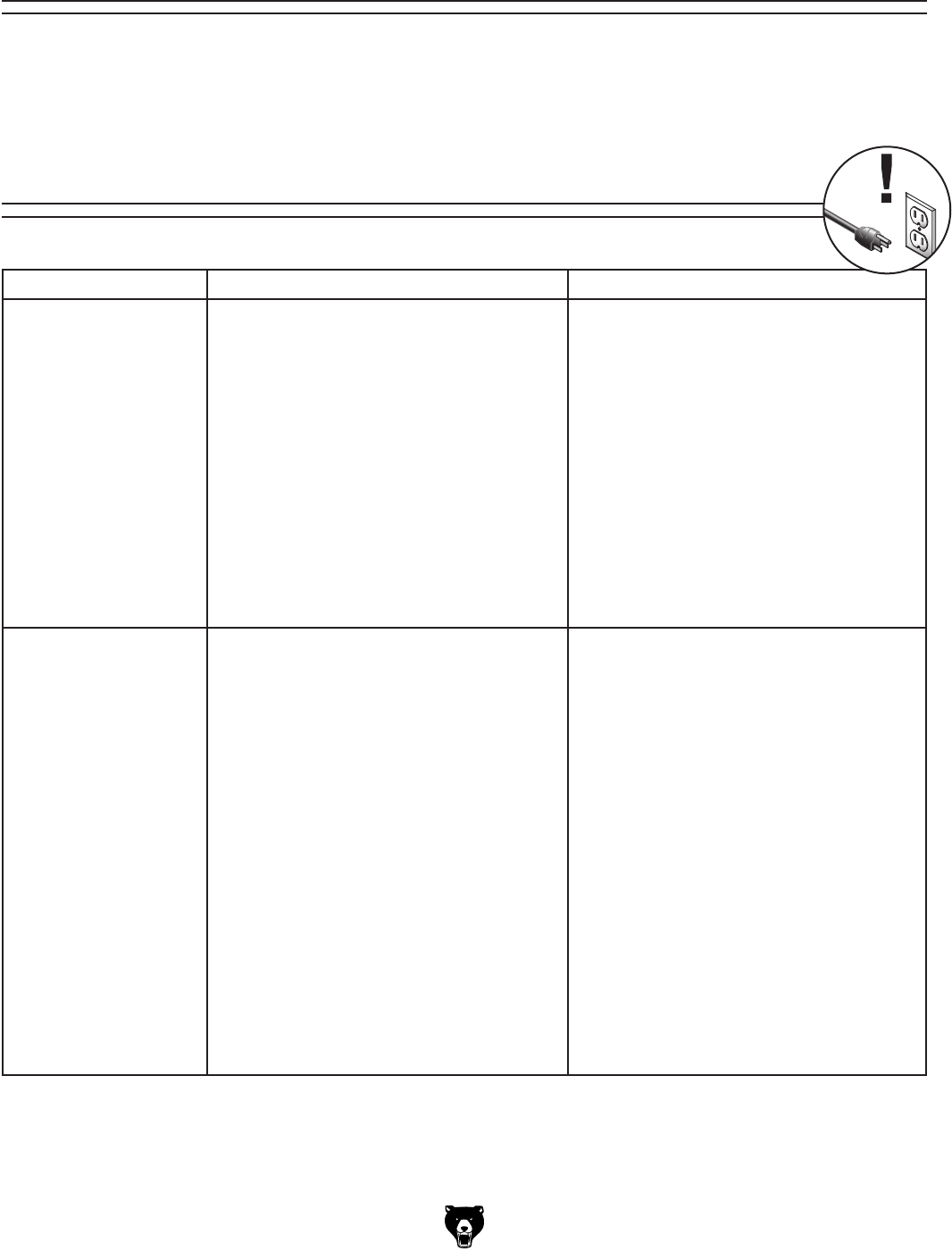

Motor & Electrical

Symptom Possible Cause Possible Solution

Machine does not start or

a breaker trips.

1. Plug/receptacle is faulty or wired incorrectly.

2. Start capacitor is faulty.

3. Motor connection is wired incorrectly.

4. Power supply is faulty, or is switched OFF.

5. Safety switch key is at fault.

6. Motor ON/OFF switch is faulty.

7. Centrifugal switch is at fault.

8. Cable or wiring is open or has high resis

-

tance.

9. Motor is at fault.

1. Test power plug and receptacle for good

contact and correct wiring.

2. Test capacitor and replace if necessary.

3. Correct motor wiring (see

Page 37).

4. Make sure hot lines and grounds are opera

-

tional and have correct voltage on all legs.

5. Install or replace safety key, or replace

switch assembly.

6. Replace faulty ON/OFF switch.

7. Adjust or replace the centrifugal switch.

8. Check for disconnected or corroded connec

-

tions, troubleshoot wires for internal or exter

-

nal breaks, then repair or replace wiring.

9. Test, then repair or replace motor.

Machine stalls or is under

-

powered.

1. Wrong workpiece material.

2. Low power supply voltage.

3. Run capacitor is faulty.

4. Filter bags are at fault.

5. V-belts are slipping.

6. Plug or receptacle is at fault.

7. Motor connection is wired incorrectly.

8. Motor bearings are at fault.

9. Machine is overloaded.

10. Motor has overheated.

11. Centrifugal switch is at fault.

12. Motor is at fault.

1. Only process wood with correct moisture

content, and no glues, or resins.

2. Make sure hot lines and grounds are opera

-

tional and have correct voltage on all legs.

3. Test capacitor and replace if necessary.

4. Empty and clean filter bag.

5. Replace bad belts, align pulleys, and re-ten

-

sion the V-belts (see

Pages 27 & 30).

6. Test power plug and receptacle for good

contact and correct wiring.

7. Correct motor wiring (see

Page 37).

8. Rotate motor shaft for noisy or burnt bear

-

ings, repair/replace as required.

9. Use new sandpaper with appropriate grit,

and reduce the feed rate/depth of sanding.

10. Check motor cooling air flow, let motor cool,

and reduce workload on machine.

11. Adjust/replace the centrifugal switch.

12. Test motor, and repair/replace if necessary.