-24- 18" & 20" Super Heavy-Duty Bandsaws

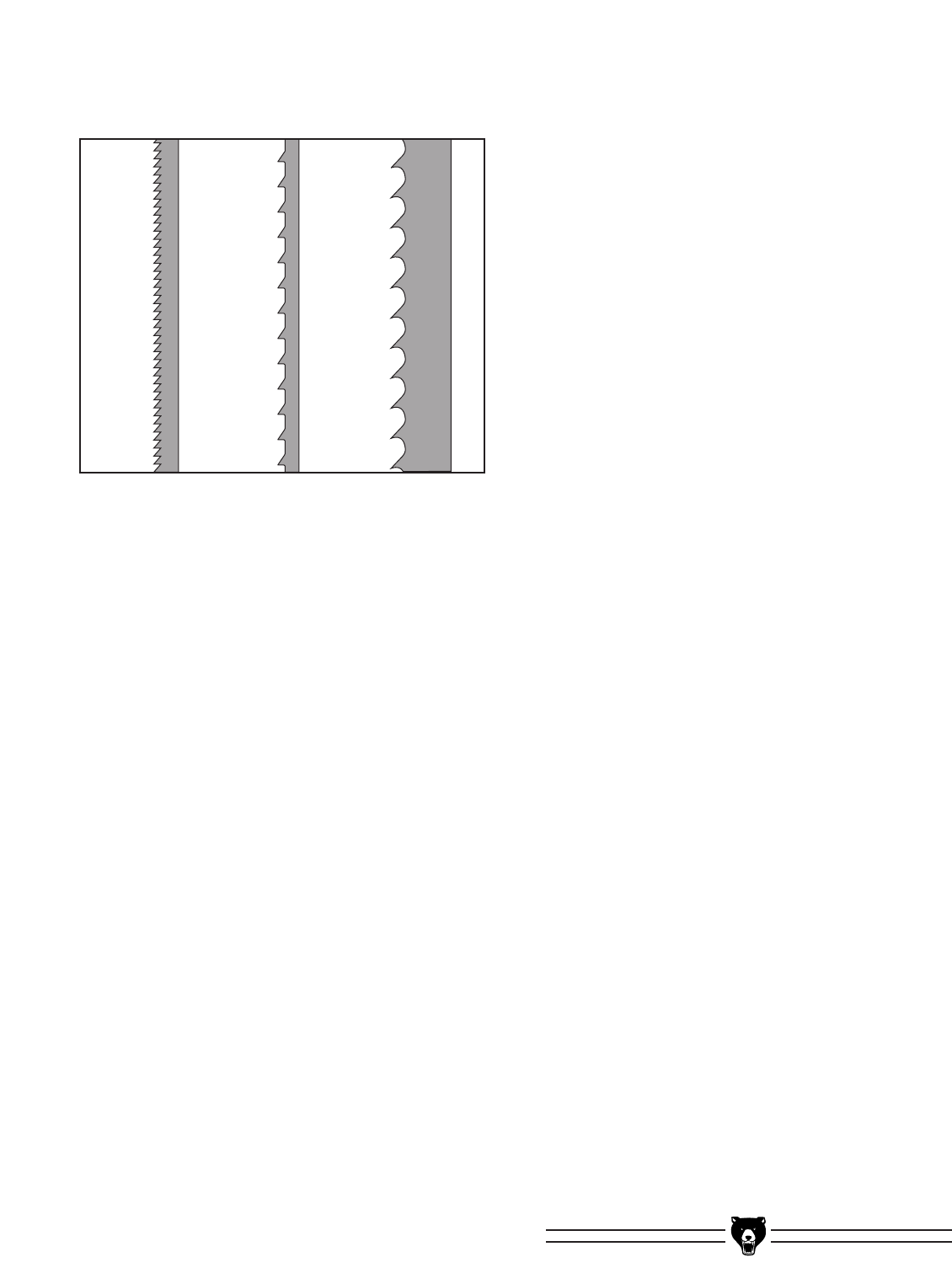

Figure 24. Raker, Skip and Hook blades.

Raker

Skip

Hook

• RAKER — This style is considered to be the

standard because the tooth size and shape

are the same as the tooth gullet. The teeth

on Raker blades are usually very numerous,

have no angle, and produce cuts by scraping

the material; these characteristics result in

very smooth cuts, but at the same time do

not cut fast and generate more heat while

cutting.These blades also work well for cut-

ting curves.

• SKIP — This style is like a raker blade that is

missing every other tooth. Because of the

design, skip toothed blades have a much

larger gullet than raker blades, and there-

fore, cut faster and generate less heat.

However, these blades also leave a rougher

cut than raker blades. Great for super

Heavy-Duty and ripping thin stock.

• HOOK — The teeth on this style have a pos-

itive angle (downward) which makes them

dig into the material, and the gullets are usu-

ally rounded for easier waste removal.

These blades are excellent for the tough

demands of resawing and ripping thick

stock.

Tooth Pitch

Usually measured as T.P.I. (teeth per inch), tooth

pitch determines the size of the teeth. More teeth

per inch (fine pitch) will cut slower, but smoother;

while fewer teeth per inch (coarse pitch) will cut

faster, but rougher. As a general rule, choose

blades that will have at least three, but not more

than twelve teeth in the material at all times. Use

fine pitched blades on harder woods and coarse

pitched blades on softer woods.

Blade Care

A bandsaw blade is a delicate piece of steel that

is subjected to tremendous strain. You can obtain

longer use from a bandsaw blade if you give it fair

treatment and always use the appropriate feed

rate for your operation.

Be sure to select blades with the proper width,

style, and pitch for each application. The wrong

choice of blades will often produce unnecessary

heat which will shorten the life of your blade.

A clean blade will perform much better than a

dirty blade. A dirty blade passes through the cut-

ting material with much more resistance than a

clean blade. This extra resistance will also cause

unnecessary heat. Maintain your blades with a

cutting blade lubricant like SLIPIT

®

(Model

G5562/3 in the Grizzly Catalog).

Blade Breakage

Many conditions may cause a bandsaw blade to

break. Blade breakage is unavoidable, in some

cases, since it is the natural result of the peculiar

stresses that bandsaw blades are subjected to.

Blade breakage is also due to avoidable circum-

stances. Avoidable breakage is most often the

result of poor care or judgement on the part of the

operator when mounting or adjusting the blade or

support guides.

The most common causes of blade breakage are:

(1) faulty alignment or adjustment of the guides,

(2) forcing or twisting a wide blade around a curve

of short radius, (3) feeding too fast, (4) tooth dull-

ness or absence of sufficient set, (5) excessive

tension, (6) top blade guide assembly set too high

above the work piece, (7) using a blade with a

lumpy or improperly finished braze or weld and

(8) running the bandsaw when not in use.

Figure 24 shows the three main categories of

tooth style.