G0609 12" Parallelogram Jointer

-15-

Moving & Placing

Jointer

The Model G0609 requires the use of lifting

equipment such as a forklift, engine hoist, or

boom crane. DO NOT lift the machine by hand.

If you are unsure how to lift this jointer, consult a

qualified professional.

To lift the jointer

:

1. Wrap lifting straps around the infeed and

outfeed tables. Position the straps as close

to the base as possible to prevent damaging

the tables.

2. With lifting straps positioned evenly, lift the

jointer (

Figure 6) off of the pallet and onto

the floor.

The Model G0609 is

an extremely heavy

machine. Serious per

-

sonal injury may occur if

safe moving methods are

not followed. To be safe,

you will need assistance

and power equipment

when moving the ship-

ping crate and remov

-

ing the machine from the

crate.

Figure 6. Model G0609 supported evenly by two

lifting straps.

Although not required, we recommend that you

mount your new machine to the floor. Because

this is an optional step and floor materials may

vary, floor mounting hardware is not included.

Generally, you can either bolt your machine to

the floor or mount it on machine mounts. Both

options are described below. Whichever option

you choose, it is necessary to level your machine

with a precision level.

Bolting to Concrete Floors

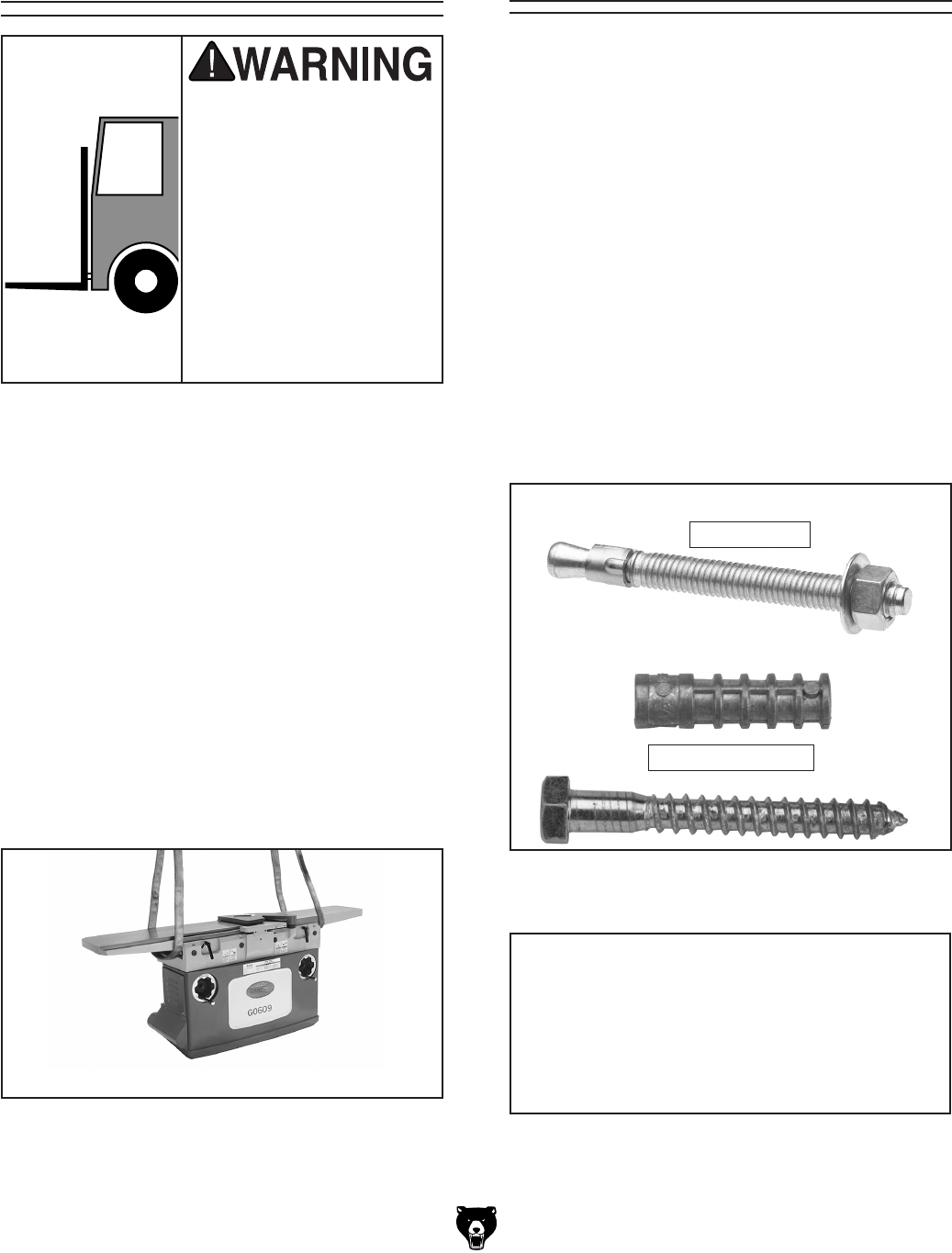

Lag shield anchors with lag bolts (Figure 7)

and anchor studs are two popular methods for

anchoring an object to a concrete floor. We sug

-

gest you research the many options and methods

for mounting your machine and choose the best

that fits your specific application.

Mounting to Shop

Floor

NOTICE

Anchor studs are stronger and more per-

manent alternatives to lag shield anchors;

however, they will stick out of the floor,

which may cause a tripping hazard if you

decide to move your machine

.

Figure 7. Typical fasteners for mounting to

concrete floors.

Anchor Stud

Lag Shield & Bolt