G0609 12" Parallelogram Jointer

-39-

3. Place the straightedge in one of the positions

shown in

Figure 49, and adjust the table (a

small hammer and punch or pin-type span

-

ner wrench may be necessary to turn the

eccentric bushings) so that the straightedge

touches the cutterhead while lying flat across

the outfeed table. Repeat this step with each

of the remaining straightedge positions as

many times as necessary until the outfeed

table is parallel with the cutterhead to within

0.010"-0.012"

.

Note: Setting the outfeed table parallel to the

cutterhead within 0.010"-0.012" will produce

high quality results. Exceeding this number

will produce minimal gain.

4. Tighten/replace the set screws in the eccen-

tric bushings on the outfeed table.

5. Remove the set screw from each of the four

eccentric bushings under the infeed table,

and loosen the set screws underneath those

removed set screws.

6. Place the straightedge halfway across the

infeed table and halfway over the outfeed

table, and adjust the infeed table even with

the outfeed table, as shown in

Figure 50.

7. Place the straightedge in one of the posi-

tions shown in

Figure 51, and adjust the

eccentric bushings under the infeed table so

the straightedge lies flat against both tables.

Repeat this step with each of the remaining

straightedge positions as many times as nec

-

essary until the infeed table is parallel with

the outfeed table.

8.

Tighten/replace the set screws in the eccen-

tric bushings on the infeed table.

Setting Outfeed

Table Height

The outfeed table height must be even with the

top of the cutterhead knives. If the outfeed table is

set too low, there will be snipe. If the outfeed table

is set too high, the workpiece will hit the edge of

the outfeed table during operation, increasing the

chance of kickback.

Tools Needed Qty

Straightedge ...................................................... 1

Wrench 17mm ...................................................

1

Wrench 19mm ...................................................

1

Hex Wrench 5mm ..............................................

1

Hex Wrench 3mm ..............................................

1

Feeler Gauge(s) 0.062" .....................................

1

To set the outfeed table height:

1. DISCONNECT JOINTER FROM POWER

SOURCE!

2. Check/adjust the table parallelism.

3. Loosen the set screws shown in Figure 10,

Page 17, remove the guard, and remove the

fence.

4. Loosen the outfeed table lock located at the

front of the machine, and loosen the jam nuts

and positive stop bolts located at the back of

the machine (see

Figure 47).

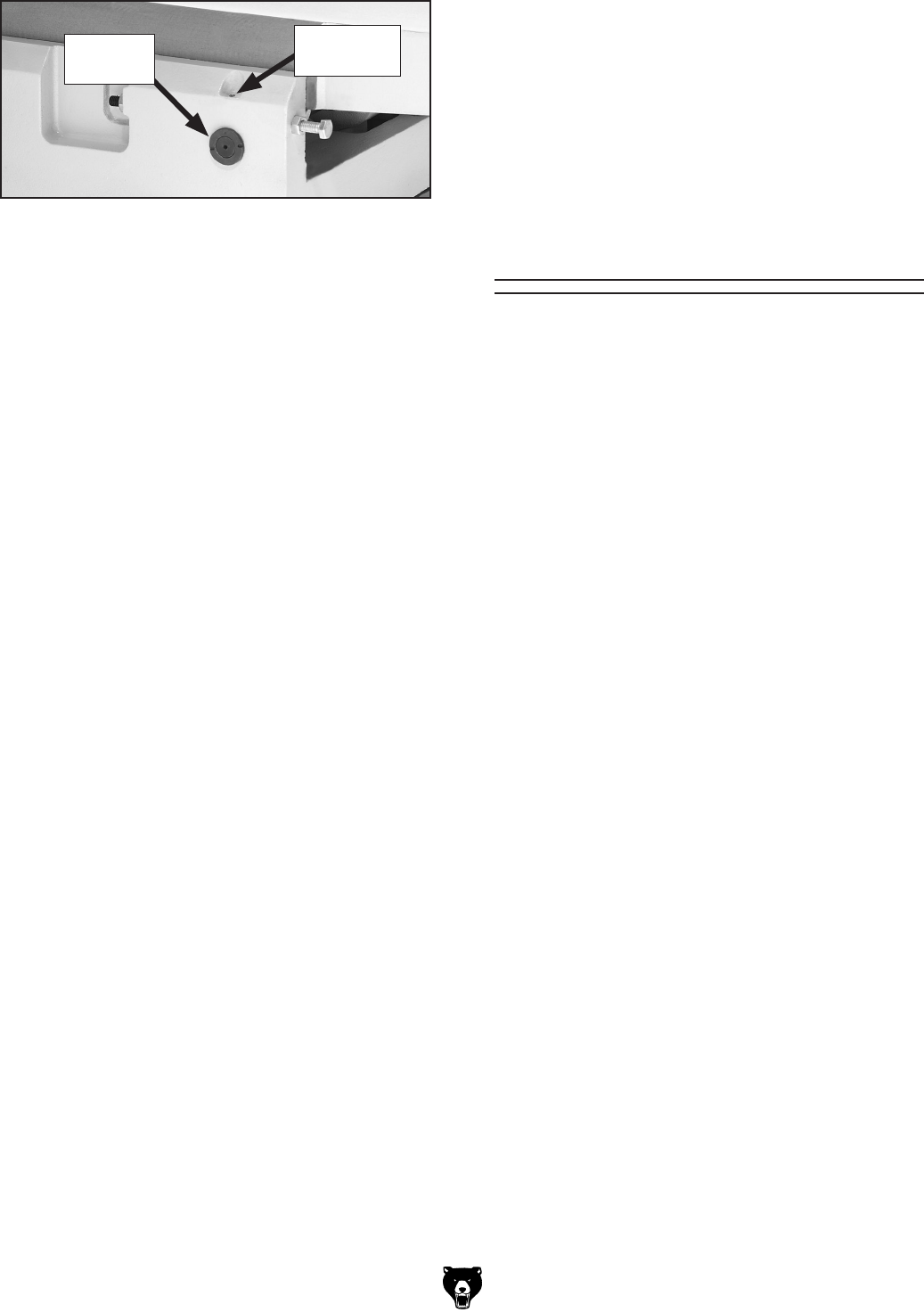

Figure 52. Eccentric bushing and set screw

location.

Eccentric

Bushing

Set Screw

Location

9. Set the outfeed table height (refer to the next

sub-section).

10. Set the knives (refer to Page 35).

11. Reinstall th

e cutterhead guard and fence.