G0609 12" Parallelogram Jointer

-35-

Tools Needed Qty

Straightedge ...................................................... 1

Knife Setting Jig (Optional) ...............................

1

Hex Wrench 3mm ..............................................

1

Wrench 10mm ...................................................

1

To adjust/replace the knives:

1. DISCONNECT JOINTER FROM POWER

SOURCE!

2. Loosen the set screws shown in Figure 10,

Page 17, remove the cutterhead guard, and

move the fence back as far as it will go.

3. Open the pulley cover to expose the cutterhead

pulley.

4. Rotate the cutterhead pulley to get access to

one of the cutterhead knives.

5. Loosen the cutterhead gib bolts, starting in

the middle, and alternating back and forth

until all of the gib bolts are loose, but not fall

-

ing out.

—If this is the first time you are setting the

knives, remove the gib and knife from the

cutterhead.

6. Remove and clean the gibs and clean inside

the cutterhead slot to remove all pitch or saw

-

dust. Coat the knives and gibs with a metal

protectant (

Page 27), then fit the gibs back in

the cutterhead with the new knives.

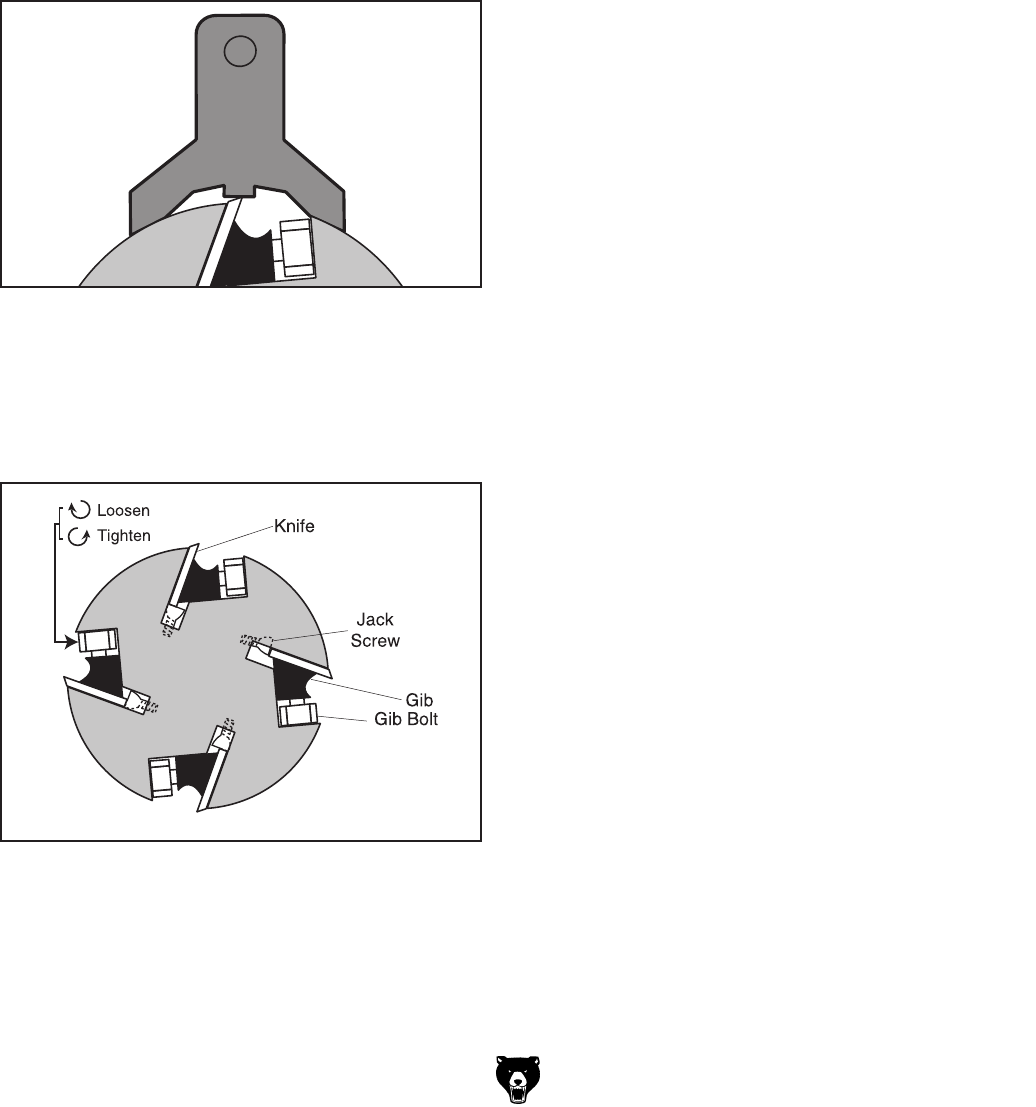

Figure 44. Cutterhead profile diagram.

The Model G0609 comes with jack screws inside

the cutterhead to adjust the knives (see

Figure

44).

Figure 43. Using knife setting jig to set knife

height.

Knife Setting Jig Method: Both tables are low-

ered to fit the jig on the cutterhead, as shown in

Figure 43, and the knife heights are set to just

touch the middle pad of the jig.

The knife setting jig makes it easy to ensure that

the knives project out of the cutterhead evenly.

After using the knife setting jig to set the knives,

you have to re-adjust the outfeed table height to

ensure that it is even with the knives at their high

-

est point of rotation. If you are using the positive

stops on the tables, they will need to also be reset

before operation.