G1021Z 15" Planer -11-

Lifting Handles

This planer is heavy and awkward to move.

We recommend that you use the proper

equipment to put the planer into position in

your shop or on a mobile base. Lifting with-

out proper equipment or ample assistance

could result in serious injury.

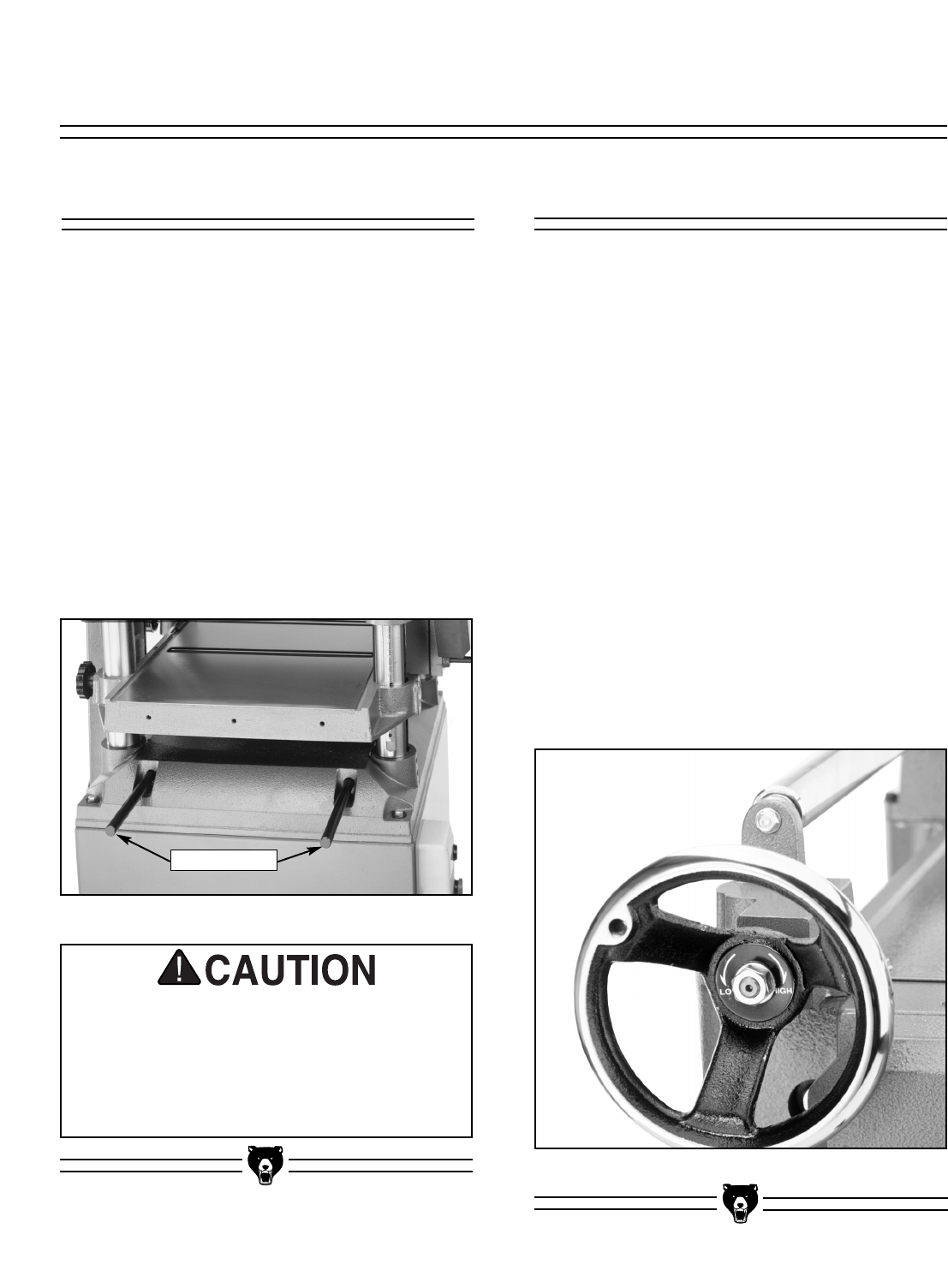

Figure 2. Location of lifting handles.

SECTION 4: ASSEMBLY

Overview

The G1021Z Planer requires very little assembly

when you receive it. There a just a few easy

assembly steps to get the machine ready for your

shop. The machine should be properly adjusted

from the factory, however should you desire to

check the various settings, the following section

will detail the proper adjustment procedures.

This planer unit is very heavy, approximately 480

lbs.There are lifting handles which slide out of the

base of the planer head (Figure 2) which can be

used to move the unit. These can be used as lift-

ing points using an overhead lift, block and tack-

le or a forklift, or if you have three other friends

who are each willing to grab a handle!

Handwheel

The handwheel is used to raise and lower the

planer table.

TO MOUNT THE HANDWHEEL:

1. The handwheel shaft is at the front right

corner of the planer. Insert the key into the

keyway on the shaft, then line up the notch

on the handwheel bore with the key. Slide

the handwheel onto the shaft.

2. Slide the direction scale over the keyed

shaft so it sits on the center face of the

handwheel. See Figure 3.

3. Secure the handwheel with the 10mm -

1.25 hex nut and washer provided.

4. Attach the handle to the outer edge of the

handwheel. The handle threads into the

hole on the handwheel.

Figure 3. Handwheel attachment.