-14-

G1033 20" Planer

Bed Rollers

After completing adjustments to the table, align

the bed rollers. The height of the bed rollers will

vary, depending on the type of material you

intend to plane. When planing rough stock, you

will need to set the rollers high to keep the lum-

ber from dragging along the bed. Milled lumber

should be planed with the rollers set lower. To

adjust the rollers correctly:

1. Lay a good quality straightedge across

both bed rollers, using a machinist's square

to keep the straightedge perpendicular to

the table.

2. Using a feeler gauge, measure the dis-

tance between the straightedge and the

table. The tolerance between the table and

the straightedge should be the same

across the table. The ideal tolerance

should be between 0'' and .015'', the larger

measurement for rougher stock. See

Figure 11. Be careful using the larger toler-

ance. Anytime the rollers are higher than

the table the potential exists for snipe, or

gouging near the end of the board

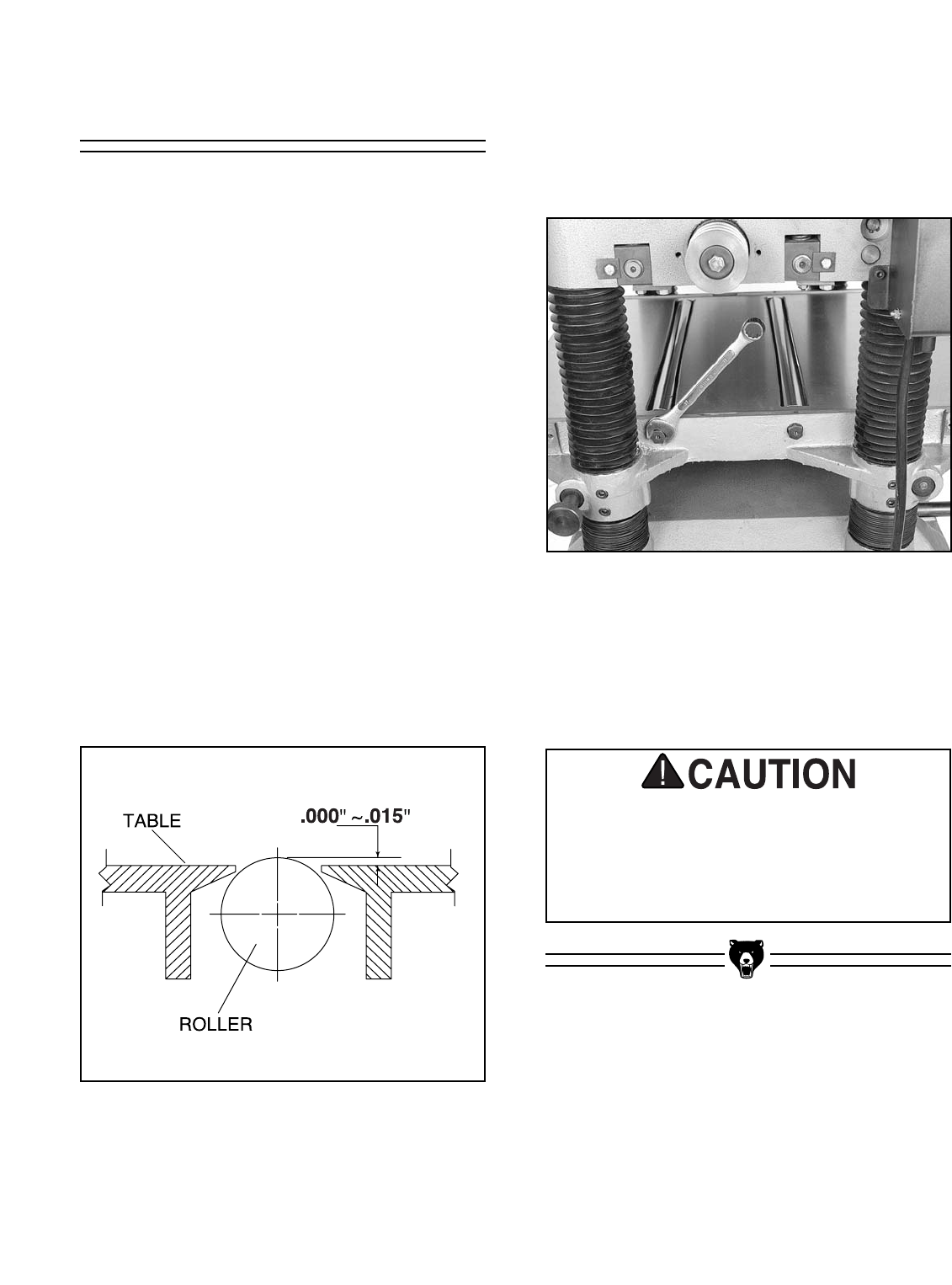

Figure 12. Roller height adjustment.

Figure 11. Bed roller tolerances.

4. Once your roller heights are corrected, re-

tighten the setscrews.

5. Spin the rollers and inspect for free move-

ment.

3. To adjust the rollers, loosen the setscrews

at the left end of the rollers and, using an

Allen

®

wrench, raise or lower the rollers on

their eccentric shafts to reach your desired

height across the table. See Figure 12.

Planer knives are dangerously sharp. Use

extreme caution when working near cutting

surfaces. Failure to exercise care while

working near knives could result in severe

injury.