Model G8688 (Mfg. 3/09+)

-21-

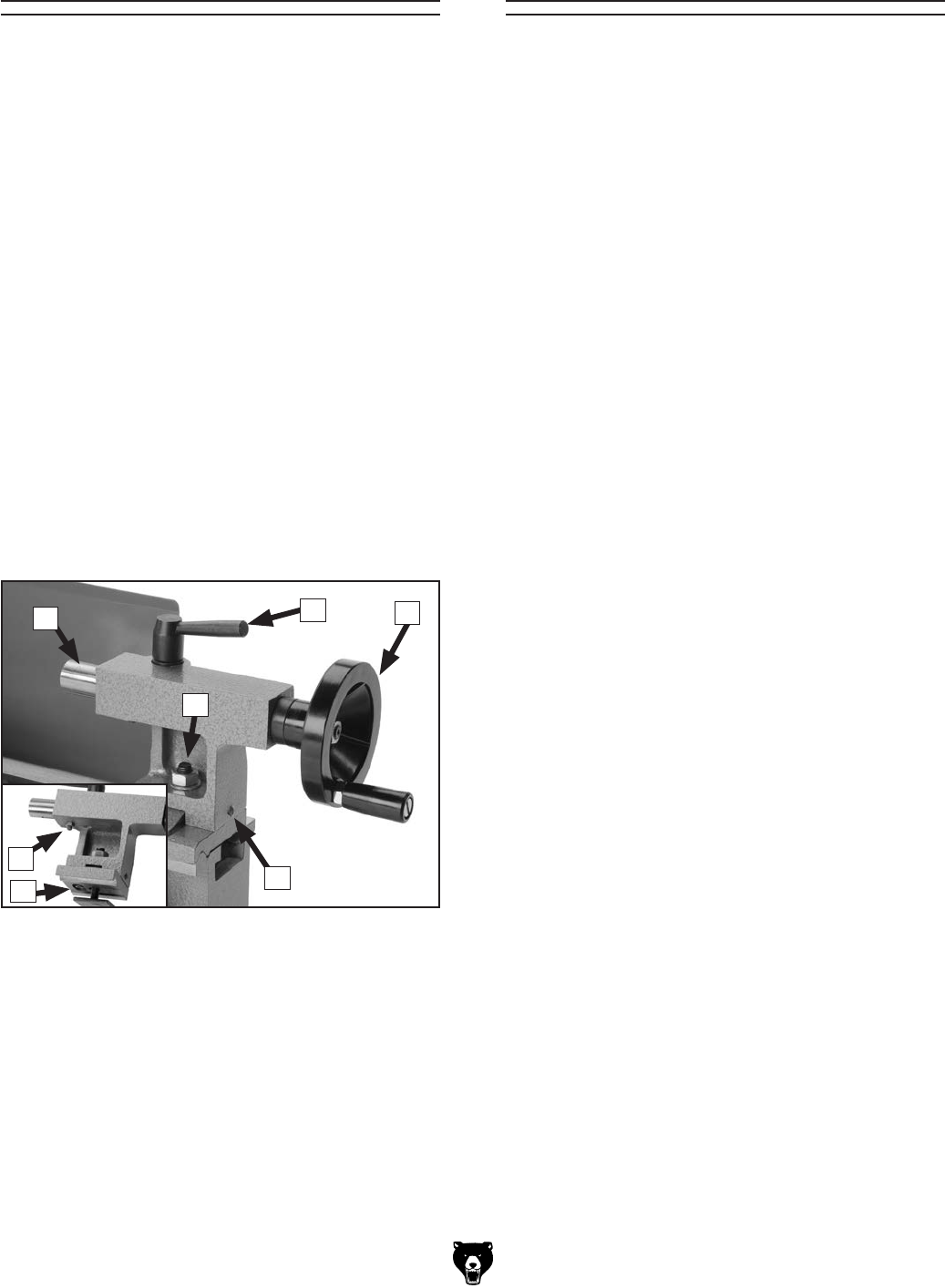

Ta il s t o c k

The tailstock may be moved along the bedway to

any desired position and locked in position by a

hex nut at its base. The tailstock quill is a MT#2

taper and will hold tools that match that taper,

such as dead center (included), live centers, drill

chucks with arbors, and drill bits with tapers.

Familiarize yourself with the tailstock components

shown in Figure 18.

A. Quill Lock: Locks the quill in position.

B. Tailstock Handwheel: Moves the quill in and

out of the tailstock.

C. Tailstock Lock Nut: Locks the tailstock in

position to the lathe bed.

D. Offset Setscrew: Helps maintain tailstock

position during tailstock offset adjustment.

E. Quill : Holds tapered tools.

F. Offset Cap Screw : Loosening allows tailstock

offset to be adjusted right or left of center.

G. Quill Gib Screw : Removes play from tailstock

quill.

Tailstock Positioning

Longitudinal Positioning

To adjust the tailstock longitudinally:

1. Using a 17mm wrench, loosen the tailstock

lock nut shown in Figure 18.

2. Slide the tailstock into position along the

bed, then tighten the clamp nut to secure the

tailstock in the new position.

Offset Positioning

Changing the tailstock offset is a common meth-

od for turning tapers. The offset cap screw is

located under the tailstock and the tailstock

must be removed from the bed for this adjust-

ment. Therefore, precision tolerances for this type

of work will require trial-and-error adjustments

(Figure 18).

To offset the tailstock:

1. Loosen the tailstock lock nut with a 17mm

hex wrench and slide the tailstock off the

lathe bed.

2. Loosen the offset cap screw just enough so

the tailstock can slide.

3. Slide the tailstock back onto the bed, then

adjust to the desired offset.

4. Tighten the setscrew to hold the tailstock in

position.

5. Carefully slide the tailstock off of the bed,

then tighten offset cap screw.

6. Slide the tailstock back onto the bed, lock it in

position and recheck your setting.

7. Repeat these steps as often as needed to

obtain your desired results.

8. For re-alignment refer to Page 36.

Figure 18. Tailstock controls.

D

E

F

G

A

B

C