-26-

Model G8688 (Mfg. 3/09+)

The Model G8688 can be geared for a variety of

different feed rates, so a chart is placed on the

drive cover of the lathe that explain how to set up

the gear combinations for threads per inch. The

chart for metric thread pitches is included in the

manual. See Figure 27 for reference.

Threading Chart: By arranging the gears as

shown on the threading charts (see Figures 25

– 26), you can set up the automatic carriage feed

to cut any of the threads per inch (TPI) or metric

thread pitches indicated.

Gear Charts

TPI GEARS TPI GEARS

A B C D A B C D

12 40 65

⁄

30 26 40 60

⁄

65

13 40 65 60 30 28 20 65

⁄

35

14 40 65

⁄

35 32 20 65

⁄

40

16 40 65

⁄

40 36 20 65

⁄

45

18 40 65

⁄

45 38 20 50 60 57

19 40 50 60 57 40 20 65

⁄

50

20 40 65

⁄

50 44 20 65

⁄

55

22 40 65

⁄

55 48 20 65

⁄

60

24 40 65

⁄

60 52 20 60

⁄

65

Figure 25. Threads per inch chart (TPI).

mm/

pitch

Gear

A B C D

0.4 20 50 40 60

0.5 20 50 ⁄ 60

0.6 40 50 30 60

0.7 40 50 35 60

0.8 40 50 40 60

1.0 20 60 ⁄ 30

1.25 50 40 ⁄ 60

1.5 40 60 ⁄ 40

1.75 35 60 ⁄ 30

2.0 40 60 ⁄ 30

Figure 26. Metric thread pitch chart.

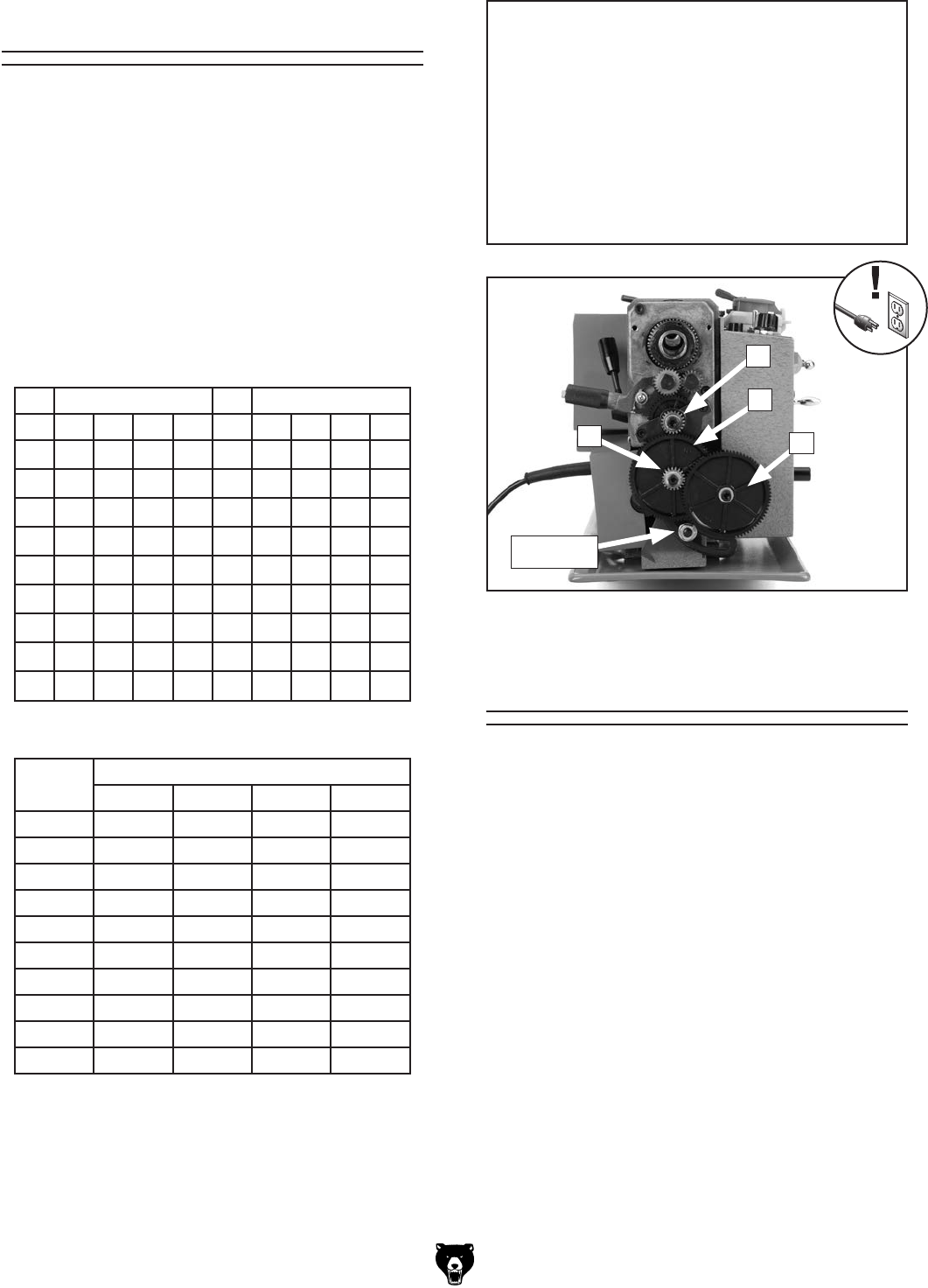

Figure 27 shows the locations of the gears refer-

enced in the gear charts Figures 25 & 26.

For example if you wanted to cut a

1

⁄2" x 13

thread on a piece of round stock.

1. UNPLUG THE LATHE!

2. Remove the gear cover.

3. Loosen the adjuster to disengage the gears

from each other.

4. Remove the gears in place and replace with

the 40, 65, 60, & 30 tooth gears in the called

out positions.

5. Position the adjuster so the gears mesh.

NOTICE

There are many details to thread cutting

and other lathe operations. It is not within

the scope of this manual to cover detailed

information regarding types of cutting tools,

cutting speeds and working with different

types of metal. If you do not have training

in this area you MUST seek training from a

qualified person before proceeding!

Figure 27. Gear positions.

A

D

C

B

Adjuster

Change Gears