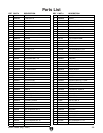

-32-

Model G8688 (Mfg. 3/09+)

SYMPTOM POSSIBLE CAUSE CORRECTIVE ACTION

Entire machine vibrates

excessively upon startup

and while running.

1. Workpiece is unbalanced.

2. Loose or damaged belt(s).

3. V-belt pulleys are not properly

aligned.

4. Worn or broken gear present.

5. Chuck or faceplate has become

unbalanced.

6. Spindle bearings badly worn.

1. Reinstall workpiece so it is as centered with the

spindle bore as possible.

2. Tighten/replace the belt as necessary.

3. Align the V-belt pulleys.

4. Inspect gears and replace if necessary.

5. Rebalance chuck or faceplate; contact a local

machine shop for help.

6. Replace spindle bearings.

Bad surface finish. 1. Wrong RPM or feed rate.

2. Dull tooling or poor tool selection.

3. Too much play in gibs.

4. Tool too high.

1. Adjust for appropriate RPM and feed rate.

2. Sharpen tooling or select a better tool for the intend-

ed operation.

3. Tighten gibs.

4. Lower the tool position.

Can't remove tapered tool

from tailstock quill.

1. Quill had not retracted all the way

back into the tailstock.

2. Debris was not removed from taper

before inserting into quill.

1. Turn the quill handwheel until it forces taper out of

quill.

2

. Always make sure that taper surfaces are clean.

Cross slide, compound

slide, or carriage feed has

sloppy operation.

1. Gibs are out of adjustment.

2. Handwheel is loose.

3. Lead screw mechanism worn or

out of adjustment.

1. Adjust gib screw(s) (see Page 35).

2. Tighten handwheel fasteners.

3. Tighten any loose fasteners on lead screw mecha-

nism.

Cross slide, compound

slide, or carriage feed

handwheel is hard to

move.

1. Gibs are loaded up with shavings,

dust, or grime.

2. Gib screws are too tight.

3. Backlash setting too tight (cross

slide only).

4. Bedways are dry.

1. Remove gibs, clean ways/dovetails, lubricate, and

readjust gibs.

2. Loosen gib screw(s) slightly, and lubricate bedways.

3. Slightly loosen backlash setting by loosening the

locking screw and adjusting the spanner ring at the

end of the handle.

4. Lubricate bedways and handles.

Cutting tool or machine

components vibrate exces-

sively during cutting.

1. Tool holder not tight enough.

2. Cutting tool sticks too far out of tool

holder; lack of support.

3. Gibs are out of adjustment.

4. Dull cutting tool.

5. Incorrect spindle speed or feed

rate.

1. Check for debris, clean, and retighten.

2. Reinstall cutting tool so no more than

1

⁄3 of the total

length is sticking out of tool holder.

3. Tighten gib screws (see Page 35) at affected com-

ponent.

4. Replace or resharpen cutting tool.

5. Use the recommended spindle speed.

Inaccurate turning results

from one end of the

workpiece to the other.

1. Headstock and tailstock are not

properly aligned with each other.

1. Realign the tailstock to the headstock spindle bore

center line (see Page 36).

Chuck jaws won't move or

don't move easily.

1. Chips lodged in the jaws. 1. Remove jaws, clean and lubricate chuck threads,

and replace jaws.

Carriage won't feed. 1. Gears are not all engaged.

2. Gears are broken.

3. Loose screw on the feed handle.

1. Adjust gear positions.

2. Replace.

3. Tighten.

Operation and Work Results