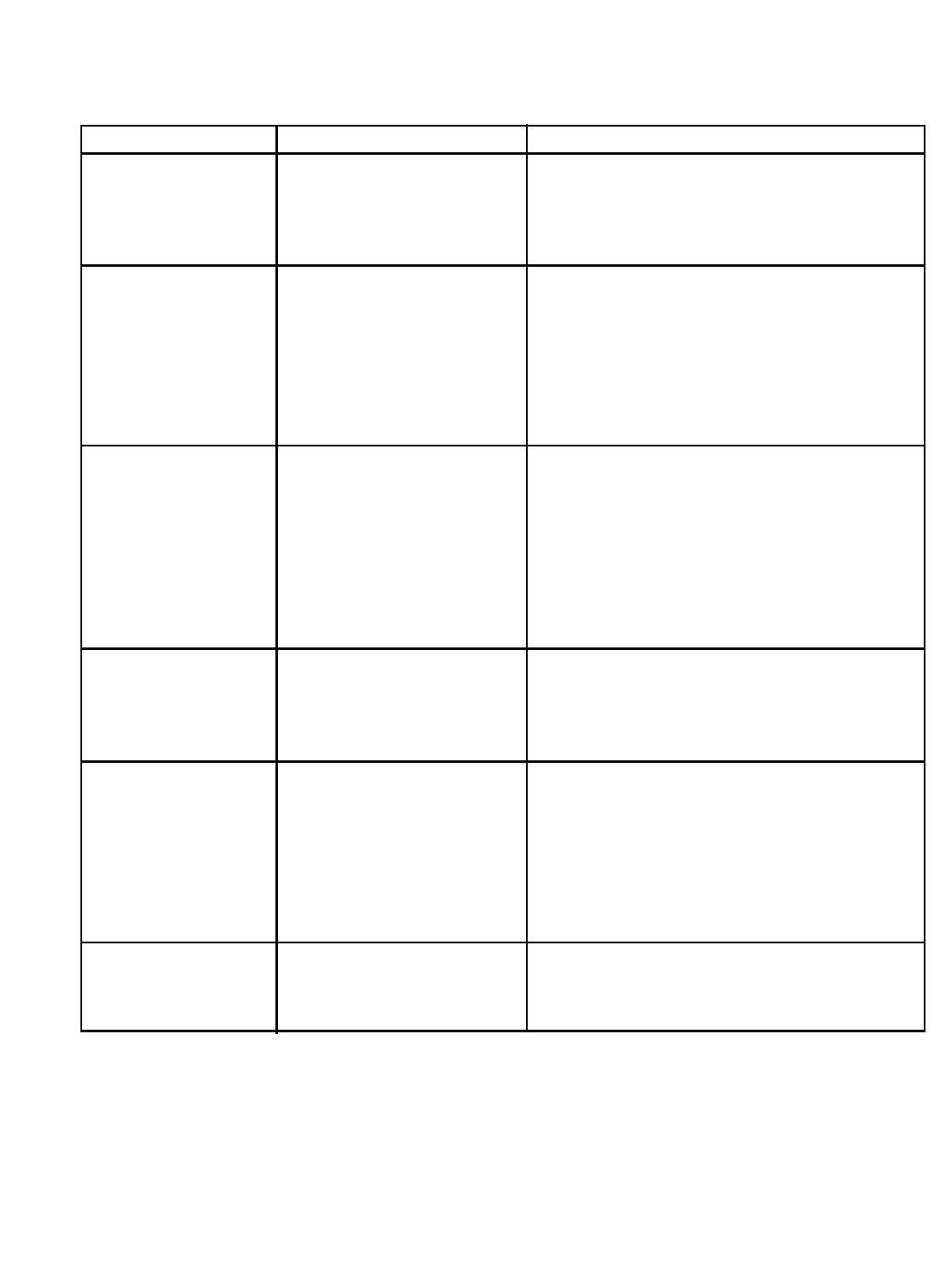

-16- G9922 Oscillating Spindle Sander

SYMPTOM

Motor will not start.

Motor will not start;

fuses or circuit break-

ers blow.

Motor fails to develop

full power (power out-

put of motor decreas-

es rapidly with

decrease in voltage at

motor terminals).

Motor overheats.

Motor stalls (resulting

in blown fuses or

tripped circuit).

Machine slows down

when operating.

TROUBLESHOOTING

POSSIBLE CAUSE

1. Low voltage.

2. Open circuit in motor or

loose connections.

1. Short circuit in line cord

or plug.

2. Short circuit in motor or

loose connections.

3. Incorrect fuses or circuit

breakers in power line.

1. Power line overloaded

with lights, appliances,

and other motors.

2. Undersized wires or cir-

cuits too long.

3. General overloading of

power company facili-

ties.

1. Motor overloaded.

2. Air circulation through the

motor restricted.

1. Short circuit in motor or

loose connections.

2. Low voltage.

3. Incorrect fuses or circuit

breakers in power line.

4. Motor overloaded.

Applying too much pres-

sure to workpiece.

CORRECTIVE ACTION

1. Check power line for proper voltage.

2. Inspect all lead connections on motor for

loose or open connections.

1. Inspect cord or plug for damaged insulation

and shorted wires.

2. Inspect all connections on motor for loose

or shorted terminals or worn insulation.

3. Install correct fuses or circuit breakers.

1. Reduce load on power line.

2. Increase wire sizes or reduce length of

wire.

3. Request a power check from the power

company.

1. Reduce load on motor.

2. Clean out motor to provide normal air circu-

lation.

1. Inspect connections on motor for loose or

shorted terminals or worn insulation.

2 Correct the low voltage conditions.

3. Install correct fuses or circuit breakers.

4. Reduce load on motor.

Feed workpiece slower.