G5959/G9957 12" Table Saw -27-

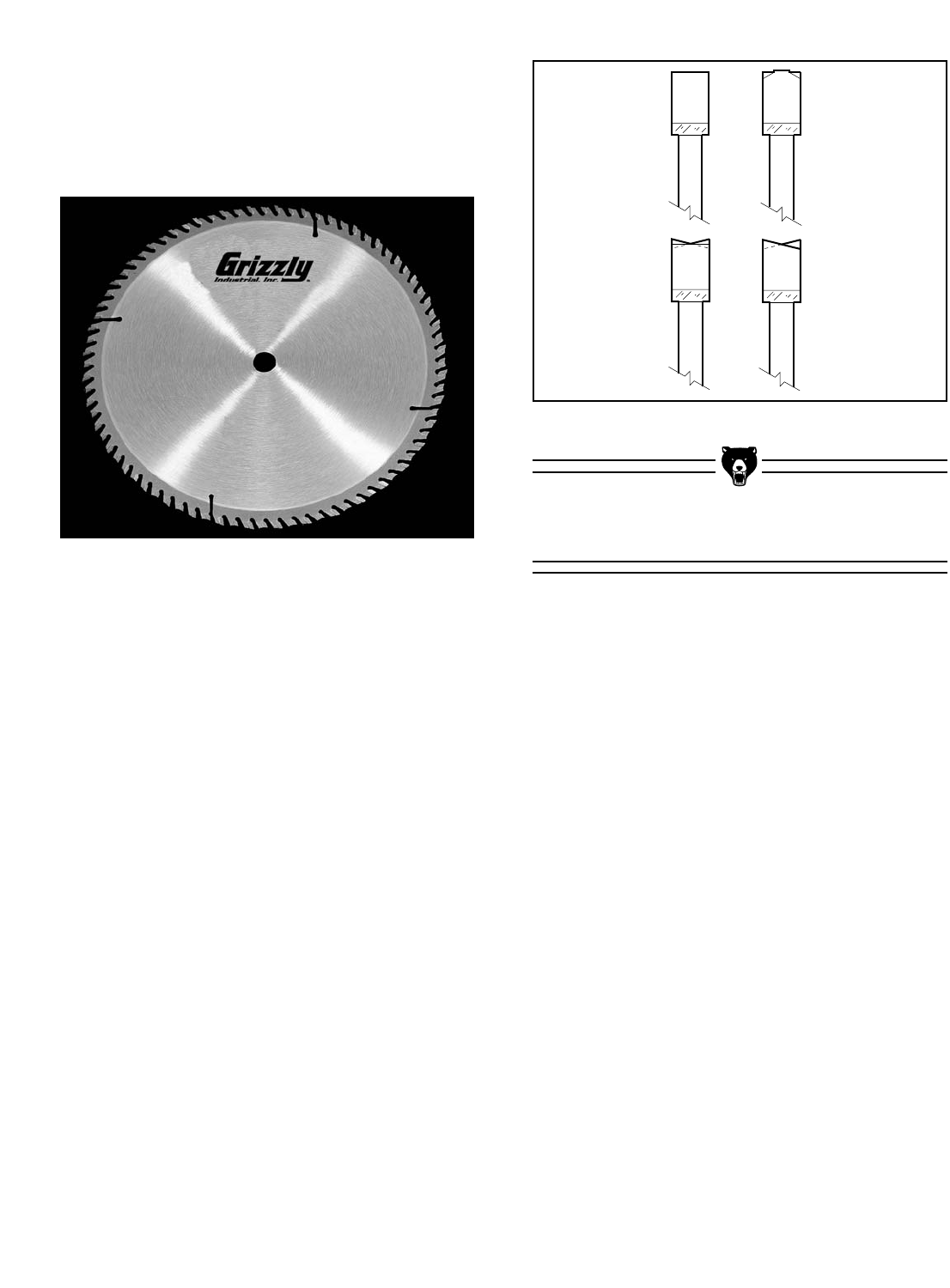

Figure 34. Plywood blade.

4. Plywood Blade: Used for cutting plywood or

veneers. A 12" plywood blade will have 60-

80 teeth, a steep alternate top bevel tooth

profile and very shallow gullet. See Figure

34.

5. Thin-kerf: Most types of saw blades are

available in a thin-kerf style. Used primarily

to minimize stock wastage. It is recommend-

ed thin-kerf blades be used in conjunction

with a blade stabilizer to reduce blade wob-

ble. Note: Most blade guards/splitters are

thicker than most thin-kerf blades. Make

sure the stock will pass by the guard/splitter

before beginning a cut.

6. Dado Blades: There are two types of dado

blades: stack and wobble. Stack dadoes are

expensive and time consuming to set up but

leave a clean and smooth finish. Stack

dadoes are used for fine furniture and cabi-

net making. Wobble dadoes are inexpensive

and easy to set up, but leave a rough finish.

7. Moulding Heads: A moulding head is a cut-

terhead that attaches to the arbor and holds

individual moulding knives. We do not rec-

ommend their use. They are very dangerous

and require training beyond the scope of this

manual.

This section on blade selection is by no means

comprehensive. Always follow the saw blade

manufacturer's recommendations to assure safe

and efficient operation of your table saw.

Figure 35. Various saw tooth cutting profiles.

Flat

Top

Blade

Alternate

Top

Bevel

Alternate

Top Bevel

And

Raker

Triple

Chip

Blade

Crosscutting

Crosscutting means cutting across the grain of

the wood. In wood products without grain (i.e.

MDF, particleboard) it simply means cutting

across the width of the stock.

Crosscuts are made with the miter gauge. There

are two miter gauge slots in the table top. Use the

one that works best for the piece being crosscut.

To make a crosscut using the miter gauge:

1. Inspect the board for soundness. You do not

necessarily need a square edge to crosscut

with accuracy.

2. Inspect the miter gauge. Is it properly set and

tight? Move the rip fence completely out of

the way.

3. Turn on the saw and allow it to come to full

speed.

4. Hold the workpiece firmly against the face of

the miter gauge and ease it into the blade as

shown in Figure 36.

5. Turn off the saw and allow the blade to come

to a full stop.