-12-

G9969 Radial Drill Press

Inventory

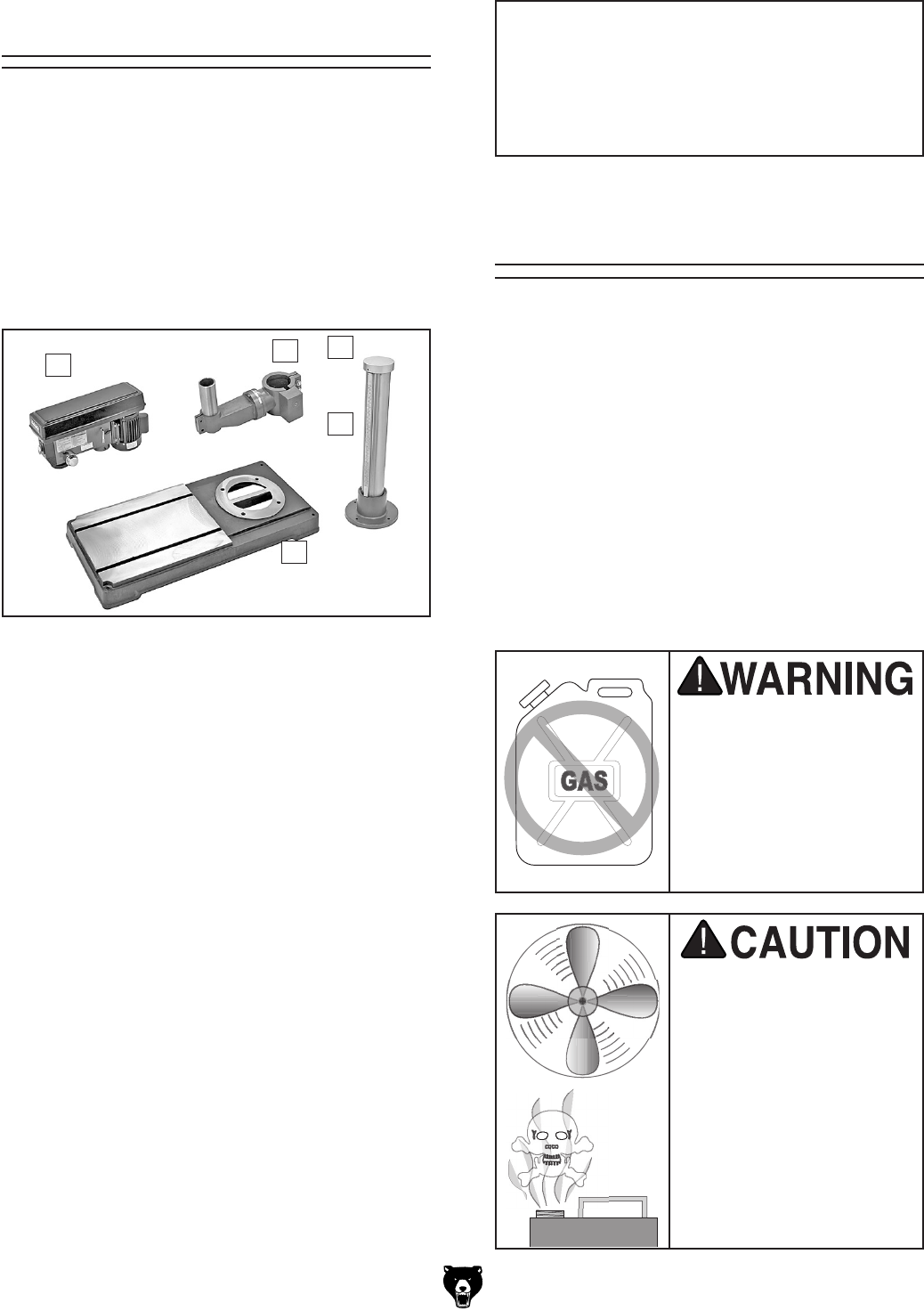

After all the parts have been removed from the

crate, you should have the following items:

Box 1: (Figure

3) Qty

A. Drill Press Headstock .................................

1

B. Headstock Bracket ..................................... 1

C.

Column Cap (attached to column) ............. 1

D. Column ....................................................... 1

E. Base ........................................................... 1

Figure 3. Major inventory components.

A

B

C

D

E

NOTICE

Some hardware/fasteners on the inventory

list may arrive pre-installed on the machine.

Check these locations before assuming that

any inventory items are missing.

Other Components and Hardware Qty

• Downfeed Handles ..................................... 3

• Lock Handles

1

⁄

4

"-20 ................................... 2

• Crank Handle Arm ......................................

1

• Crank Handle .............................................

1

• Arbor JT#3/MT#4 ....................................... 1

• Chuck JT#3 ................................................ 1

• Chuck Key ..................................................

1

• Cover Knob

1

⁄

4

"-20 ...................................... 1

• Phillips Head Screw

1

⁄

4

"-20 x

1

⁄

2

" ................. 1

• Flat Washer

1

⁄

4

" ........................................... 1

• Drift Key ...................................................... 1

• Hex Bolts

1

⁄

2

"-13 x 2" .................................. 4

• Flat Washers

1

⁄

2

" ......................................... 4

• Hex Wrenches 3, 4, 5mm ...................... 1 ea

In the event that any nonproprietary parts are

missing (e.g. a nut or a washer), we would be

glad to replace them, or for the sake of expedi

-

ency, replacements can be obtained at your local

hardware store.

The unpainted surfaces are coated with a waxy

oil to protect them from corrosion during ship

-

ment. Remove this protective coating with a sol

-

vent cleaner or citrus-based degreaser such as

Grizzly’s G7895 Degreaser. To clean thoroughly,

some parts may need to be removed. For opti

-

mum performance from your machine, make

sure you clean all moving parts or sliding

contact surfaces that are coated. Avoid chlo

-

rine-based solvents, such as acetone or brake

parts cleaner, as they may damage painted sur

-

faces should they come in contact. Always follow

the manufacturer’s instructions when using any

type of cleaning product.

Clean Up

Gasoline and petroleum

products have low flash

points and could cause

an explosion or fire if

used to clean machinery.

DO NOT use gasoline or

petroleum products to

clean the machinery.

Many of the solvents

commonly used to clean

machinery can be toxic

when inhaled or ingest

-

ed. Lack of ventilation

while using these sol

-

vents could cause seri

-

ous personal health risks

or fire. Take precautions

from this hazard by only

using cleaning solvents

in a well ventilated area.