-16-

H8126 Wide Wheel Ginder

Wheel Care

Your safety when grinding depends, in large part,

on the condition of the wheel. A wheel in poor

condition may break apart during rotation, injuring

the operator and damaging property.

Here are some tips to help you avoid breaking

the wheel:

• Always transport, store and handle wheels

with care. Wheels may be damaged if they

are dropped or if heavy objects are stacked

on them.

• Select the right grinding wheel for the job.

DO NOT grind material inappropriate for the

wheel type.

• Select the right wheel for the machine. If a

grinding wheel rotates faster than its RPM

rating, it may fly apart.

• Mount wheels properly. (See the Wheel

Replacement instructions on Page 17 for

guidance.) Never use a wheel with the wrong

arbor size for the grinder.

• Do not abuse the wheel by jamming the work

into the grinding wheel with excessive force.

• Learn how to use the grinder and the grind

-

ing wheels properly. Ask a trusted person

with experience or consult with your local

library to learn more.

• Do not store wheels in damp or wet loca

-

tions.

• Grinding on the side of the wheel may cause

wheel damage.

• Replace wheels when the diameter becomes

2" smaller than its original size.

Wheel Selection

The Model H8126 only accepts Type 1 wheels

with a

1

⁄2" bore.

Aluminum oxide and silicon carbide wheels are

marked in a somewhat uniform manner by all

major manufacturers. Understanding these mark

-

ings will help you understand the capabilities of

various wheels. Always refer to the manufactur

-

er’s grinding recommendations when selecting a

wheel for your project.

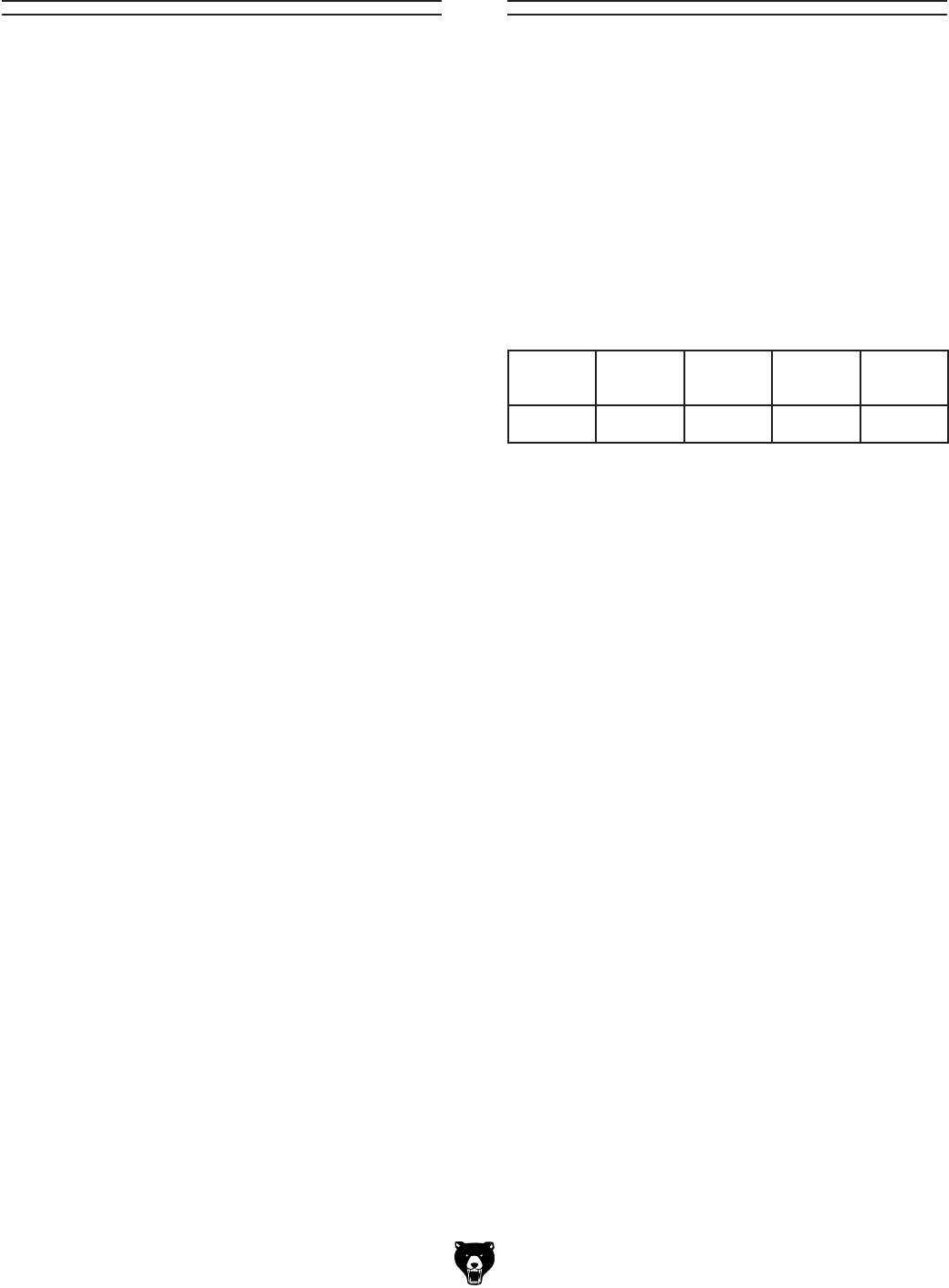

The basic format for wheel numbering is:

Prefix

Abrasive

Type

Grit Size Grade

Bond

Type

1 A 60 L V

The Prefix is the manufacturer’s designation for a

particular wheel type (eg, Type 1 wheels).

The most common Abrasive Types used are 'A'

for Aluminum Oxide, 'C' for Silicon Carbide, and

occasionally 'SG' for Seeded Gel.

The Grit Size is a number that refers to the size

of the abrasive grain in the wheel. The lower the

number, the coarser the wheel. Ten is a very

coarse wheel for roughing and 220 is usually the

upper range for fine finish work.

Grade is an indication of the hardness of the

wheel—'A' being the softest and 'Z' being the

hardest.

Bond Type refers to the type of bonding material

used to hold the abrasive material. Most general

purpose wheels will have a 'V' indicating Vitrified

Clay is used. Vitrified Clay provides high strength

and good porosity. The other common bond type

is 'B' for resin where synthetic resins are used.

These are used to grind cemented carbide and

ceramic materials.

Note:

There may be other numbers inserted that

have meaning for a particular type of wheel. Refer

to the manufacturer’s technical data for a com

-

plete explanation.