H8126 Wide Wheel Grinder

-17-

Wheel Inspection

Do not assume that a wheel is in sound condition

just because it is new—often damage can occur

in shipping, with age, or with exposure to mois

-

ture. Inspect every wheel for damage.

First, do a Visual Inspection. Look for any

cracks, chips, nicks or dents in the surface of the

wheel. If you see any of these, DO NOT use the

wheel.

Second, do a Ring Test, by following Steps 1-5

below. This test will give you an indication of any

internal damage that may not be obvious during

a visual inspection.

Always be sure to use a wheel that is rated for

3450 RPM or greater.

To perform a Ring Test:

1. Make sure the wheel that you test is clean and

dry; otherwise, you may get false results.

2. If size permits, balance the wheel with your

finger in the hole. If this is not possible, hang

the wheel in the air with a piece of cord or

string looped through the hole in the center.

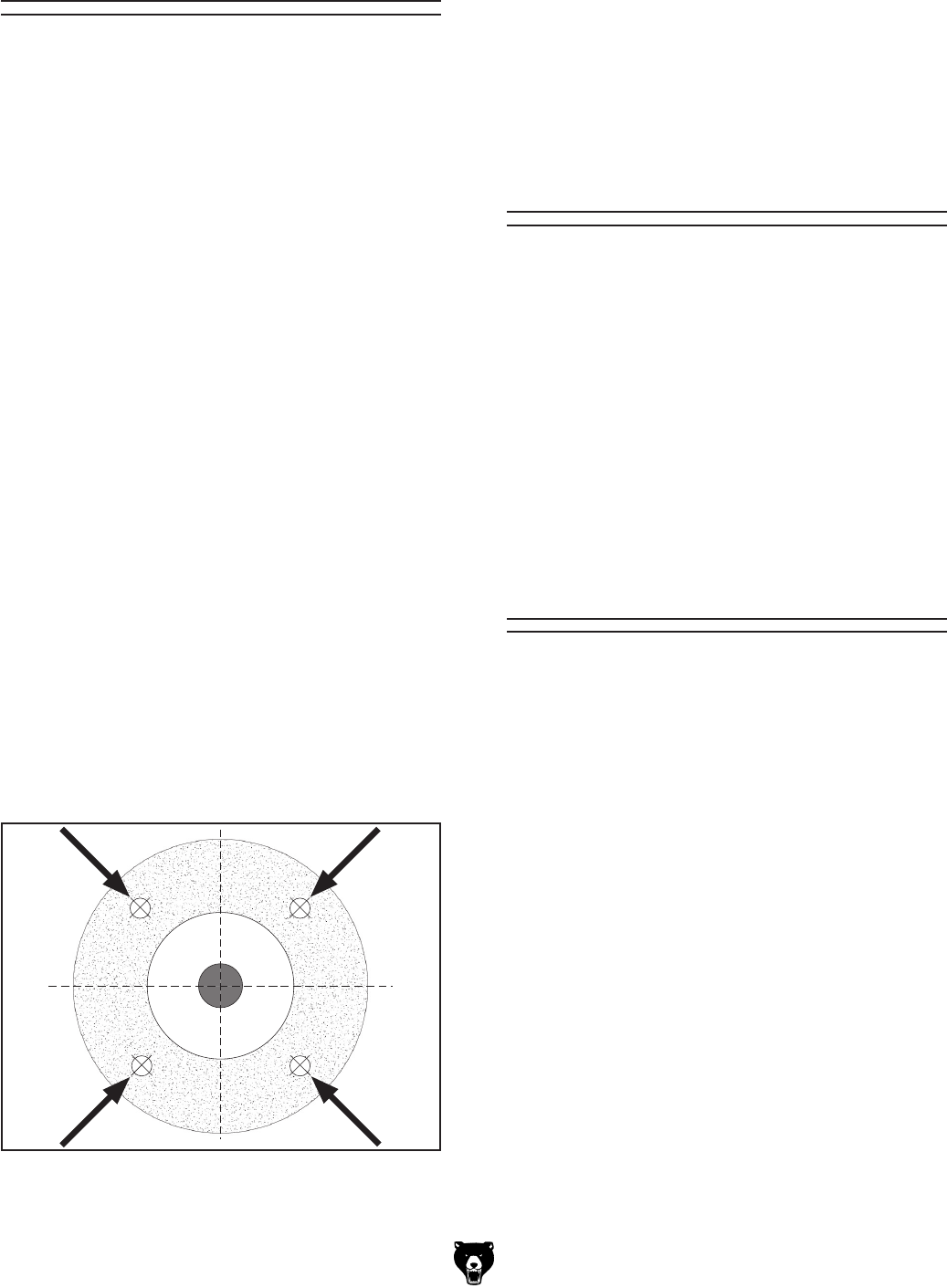

3. At the spots shown in Figure 11, gently tap

the wheel with a light non-metallic device

such as the handle of a screwdriver or a

wooden mallet.

Figure 11. Tapping locations when performing a

ring test.

4. An undamaged wheel will emit a clear metal-

lic ring or “ping” sound in each of these spots.

A damaged wheel will respond with a dull

thud that has no clear tone.

5. If you determine from the ring test that the

wheel is damaged, DO NOT use it!

Wheel Dressing

Depending on the type of grinding you do, the

grinding wheel may require periodic dressing.

Several different kinds of wheel dressing devices

are available (see Page 19). Dressing restores

the abrasive quality of the wheel surface and

squares up the wheel edge.

Refer to the instructions that accompany your

dressing accessory for complete details on how

to properly dress a wheel.

Wheel Replacement

The wheel guard assembly must be removed in

order to mount or dismount a grinding wheel.

To replace a grinding wheel

:

1. DISCONNECT THE GRINDER FROM

POWER!

2. Remove the three Phillips head screws and

nuts that go through the outer guard, and

remove the outer guard.

3. Block the wheel from turning, then remove

the arbor nut that secures the wheel.

Note: The arbor shaft and nut on the left

side of the grinder (as you face front) has

left hand threads; to loosen this nut, turn it

clockwise.