-12-

Model T25100 (Mfg. Since 8/12)

Basic Controls &

Components

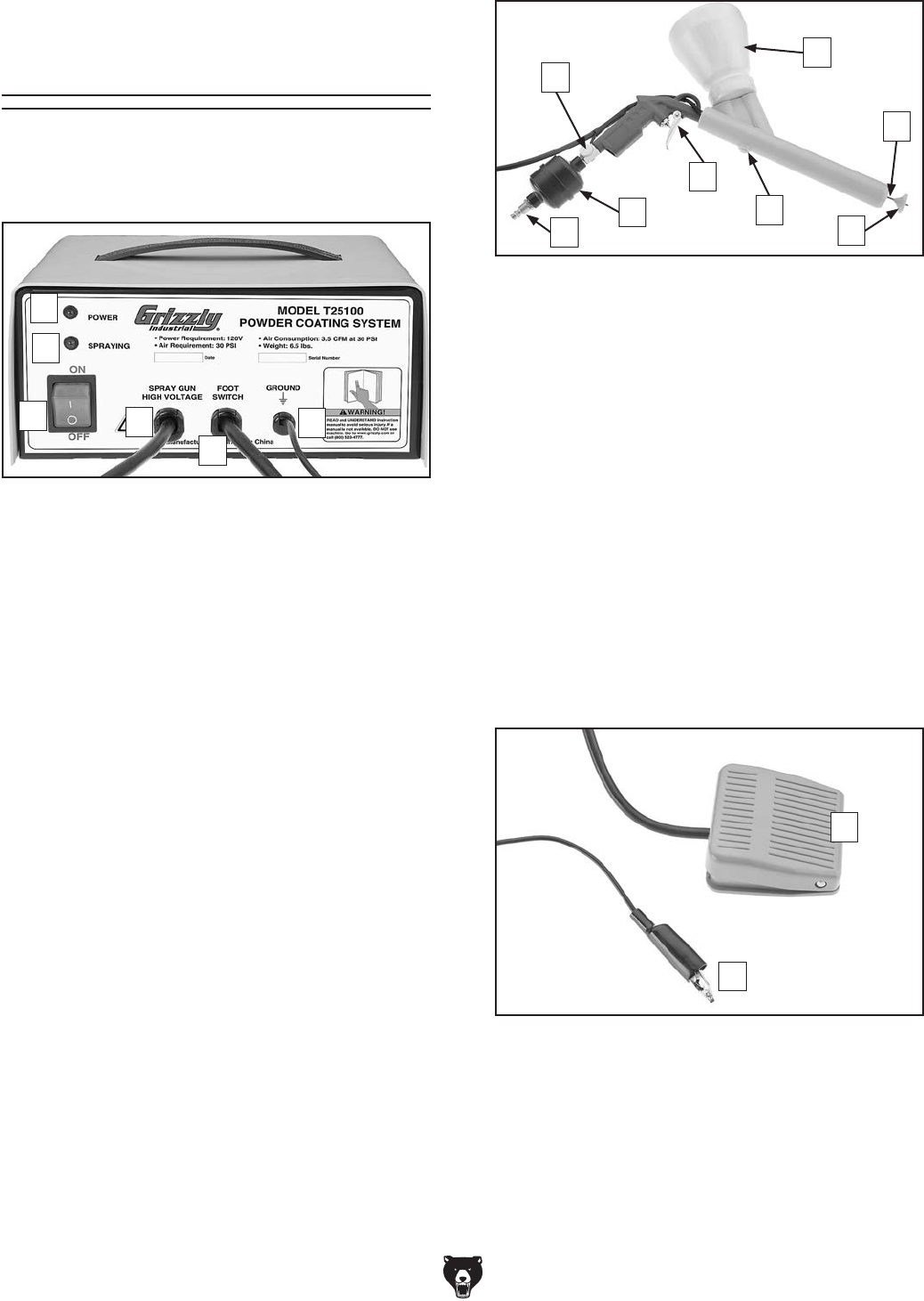

Use Figures 5–7 and the following descriptions to

gain a better understanding of the Model T25100

controls and components.

Figure 5. Control box panel.

A

B

C

D

E

F

A. Power Lamp. Illuminates when power is

enabled to the control box.

B. Spraying Lamp. Illuminates when power is

enabled to the spray gun.

C. ON/OFF Switch. Enables power to the con-

trol box.

D. Spray Gun Cable. Connects the spray gun

to the control box.

E. Foot Switch Cable. Connects the foot switch

to the control box.

F. Grounding Cable. Provides an electrical

ground for the workpiece.

G. Air Quick-Connect. Provides a

1

⁄4" NPT con-

nection for incoming air pressure.

H. Moisture Filter. A disposable unit that

removes moisture from the incoming air. We

recommend that you also use an additional

in-line moisture filter on the air compressor.

I. Air Pressure Regulating Valve. Increases/

decreases air flow to the spray gun.

J. Spray Gun Trigger. Enables air to flow

through the powder cup and gun. To begin

spraying, use the spray gun trigger and the

foot switch simultaneously.

K. Powder Cup. Holds the powder coating

material. Air is circulated inside the cup to

provide a fine dust for spraying.

L. Powder Flow Regulating Screw. Fine tunes

the flow of powder from the gun.

M. Conductor Pole. Electrically charges the

powder dust as it leaves the spray gun.

N. Scatter Tip. Provides the spray pattern for

the powder dust.

Figure 7. Foot switch and grounding clip.

O

P

O. Foot Switch. Enables power to the spray

gun conductor pole. To begin spraying use

the foot switch and the spray gun trigger

simultaneously.

P. Grounding Clip. Provides an electrical

ground for the workpiece.

Figure 6. Spray gun controls.

J

K

N

M

G

H

I

L